Standby preheating device and method for molten steel refining vacuum channel

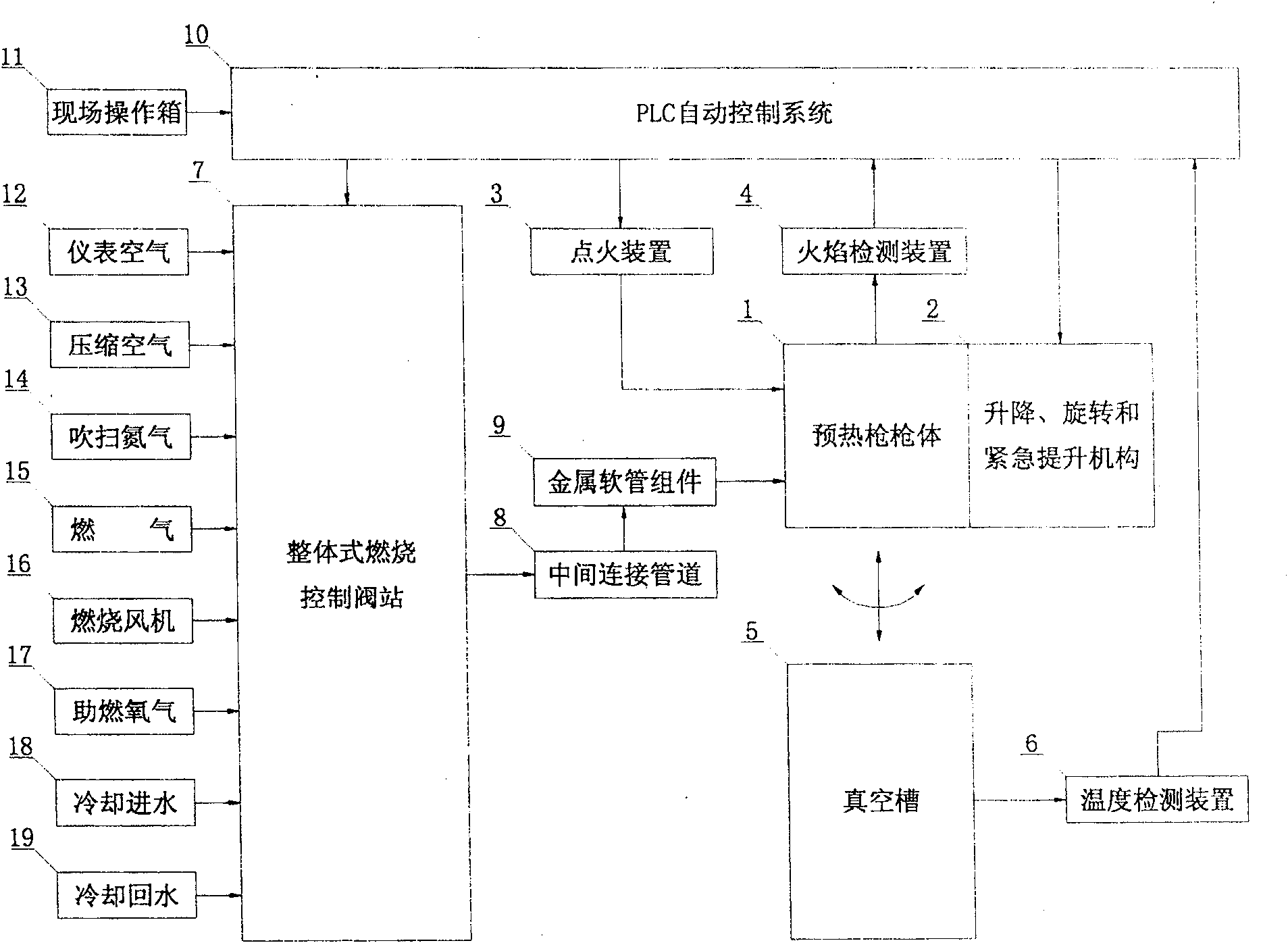

The technology of a preheating device and a vacuum tank is applied in the field of molten steel refining, which can solve the problems of short service life of the vacuum tank, cumbersome operation and high cost, and achieve the effects of satisfying the requirements of preheating treatment, simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

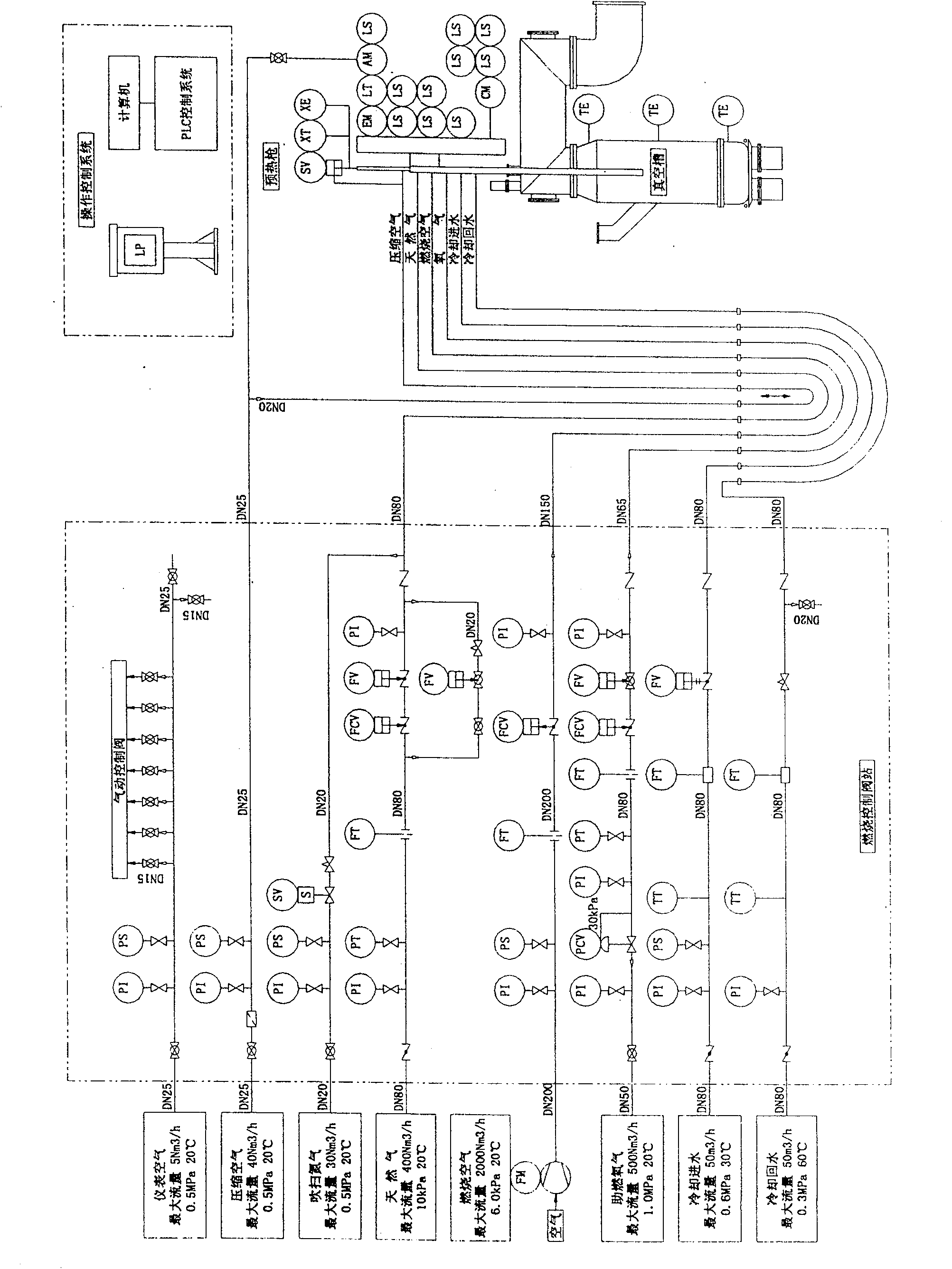

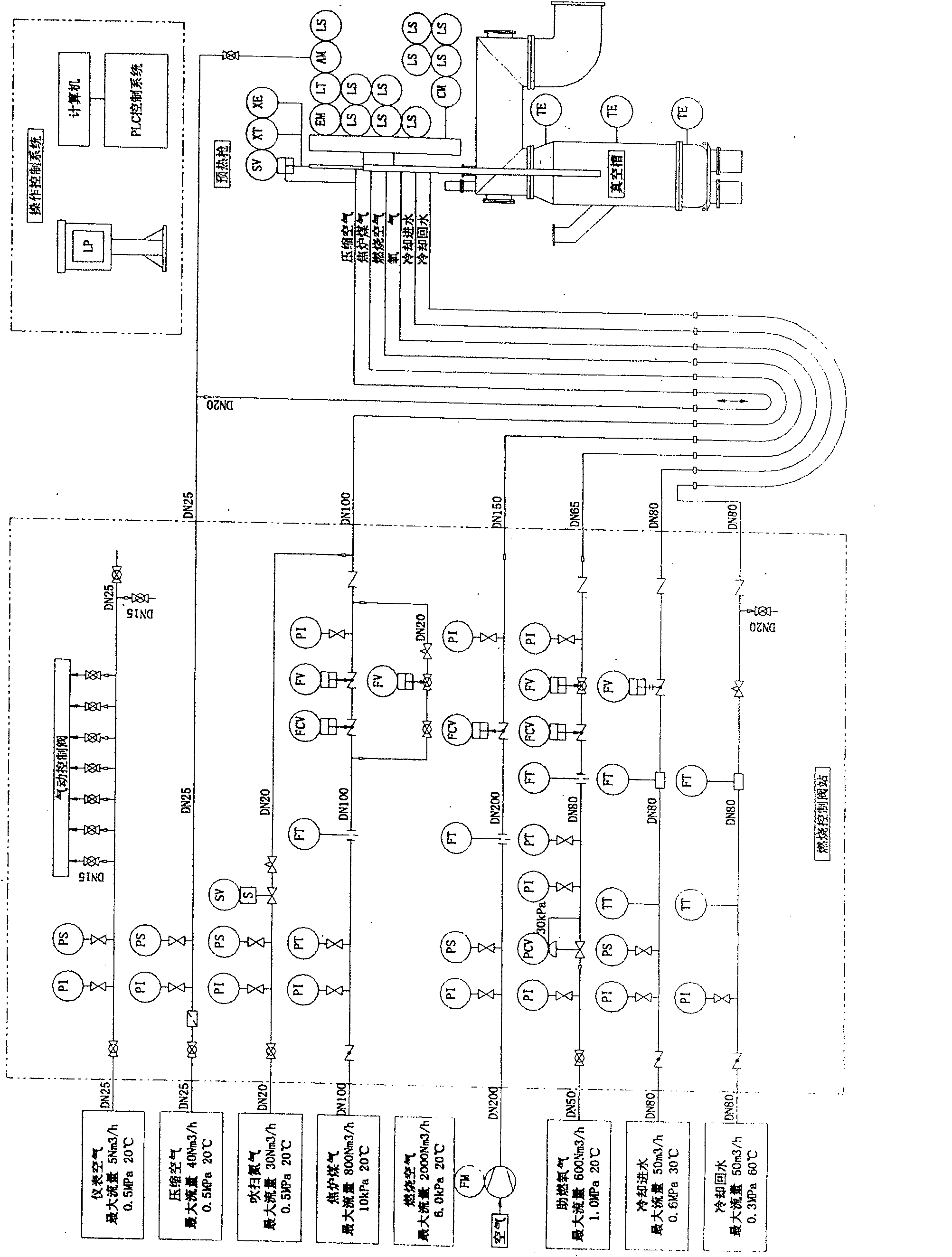

[0014] Below are two typical process schemes of the present invention.

[0015] The first is the 150-ton RH molten steel refining vacuum tank standby preheating device using natural gas as the gas, as attached figure 2 As shown, the main process design data are as follows: the preheating rate of vacuum tank 5 is 50°C / hour, and the maximum heating temperature is 1200°C; the maximum lifting stroke of preheating gun 1 is 10 meters; the maximum flow rate of natural gas is 400Nm 3 / h, the working pressure is 10kPa, the main gas piping of the valve station and the gas piping of the preheating gun are both DN80; the bypass ignition natural gas flow rate is 20Nm 3 / h, the bypass piping is DN20; the maximum flow of combustion air is 2000Nm 3 / h, the working pressure is 6.0kPa, the combustion air piping of the valve station is DN200, and the combustion air piping of the preheating gun is DN150. The maximum flow rate of combustion oxygen is 500Nm 3 / h, the primary interface pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com