Laser beam machine

A laser instrument and laser beam technology, applied in the field of laser instruments, can solve the problems of difficult to divide workpiece processing failure areas, and the degraded layer cannot be uniformly exposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

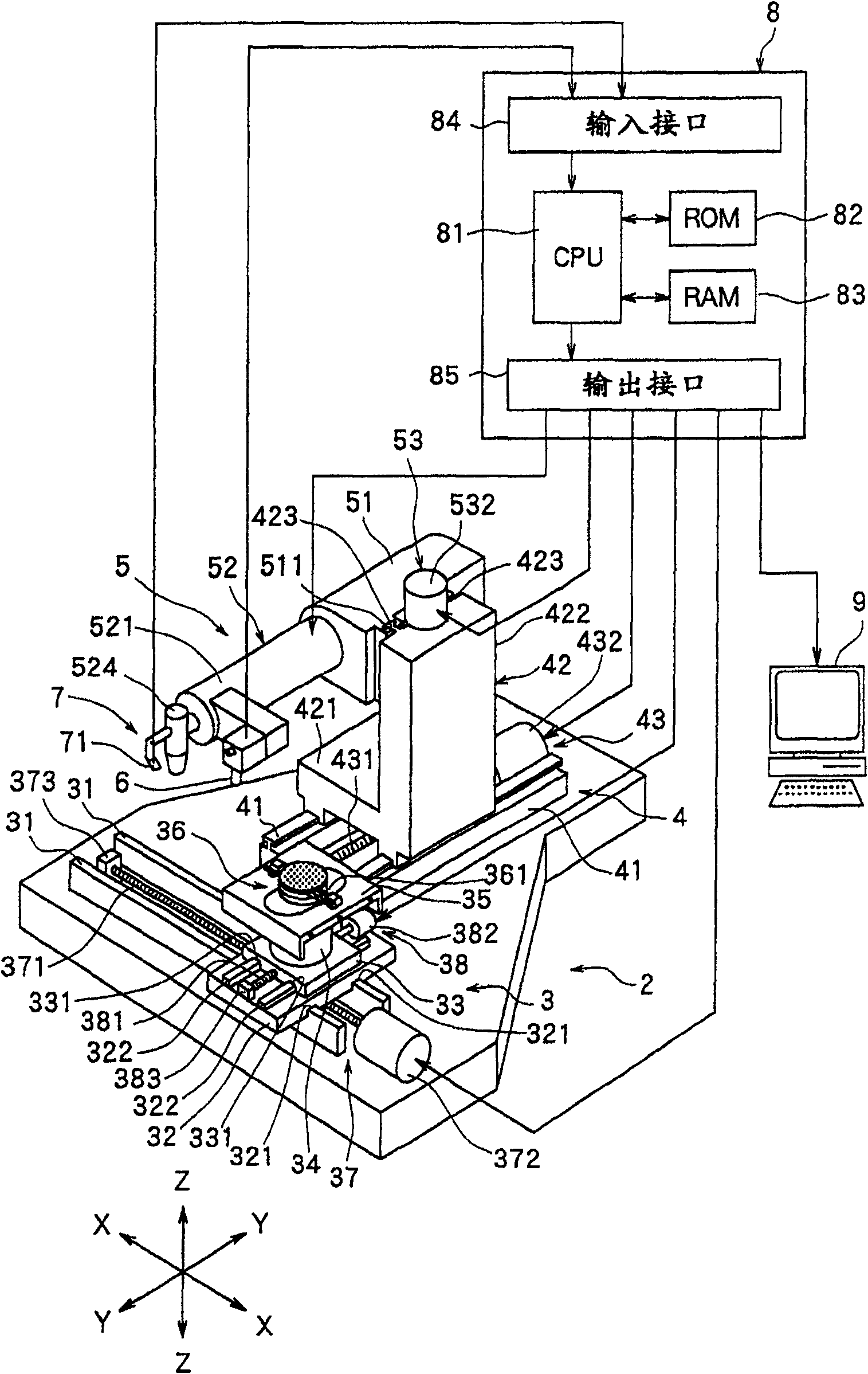

[0022] The laser apparatus according to the preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] figure 1 It is a perspective view of a laser instrument manufactured according to the present invention. figure 1 The laser instrument shown in includes: a fixed base 2; a chuck table mechanism 3 for clamping a workpiece, which is mounted on the fixed base 2 in a movable manner along the processing and feeding direction indicated by arrow X; and the laser beam application unit supports The mechanism 4 is mounted on the fixed base 2 in a movable manner along the indexing feed direction indicated by the arrow Y, the direction indicated by the arrow Y is perpendicular to the direction indicated by the arrow X; and the laser beam application unit 5, which It is mounted on the laser beam application unit support mechanism 4 in a movable manner in the direction indicated by arrow Z.

[0024] The above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com