Intensified connection member for cable bridge

A technology for connecting components and cable bridges, which is applied in the field of strong connecting components for cable bridges, can solve the problems of easy to form safety hazards, limited service life, weak fixing strength, etc., and achieve the effects of wide application range, easy adjustment, and convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

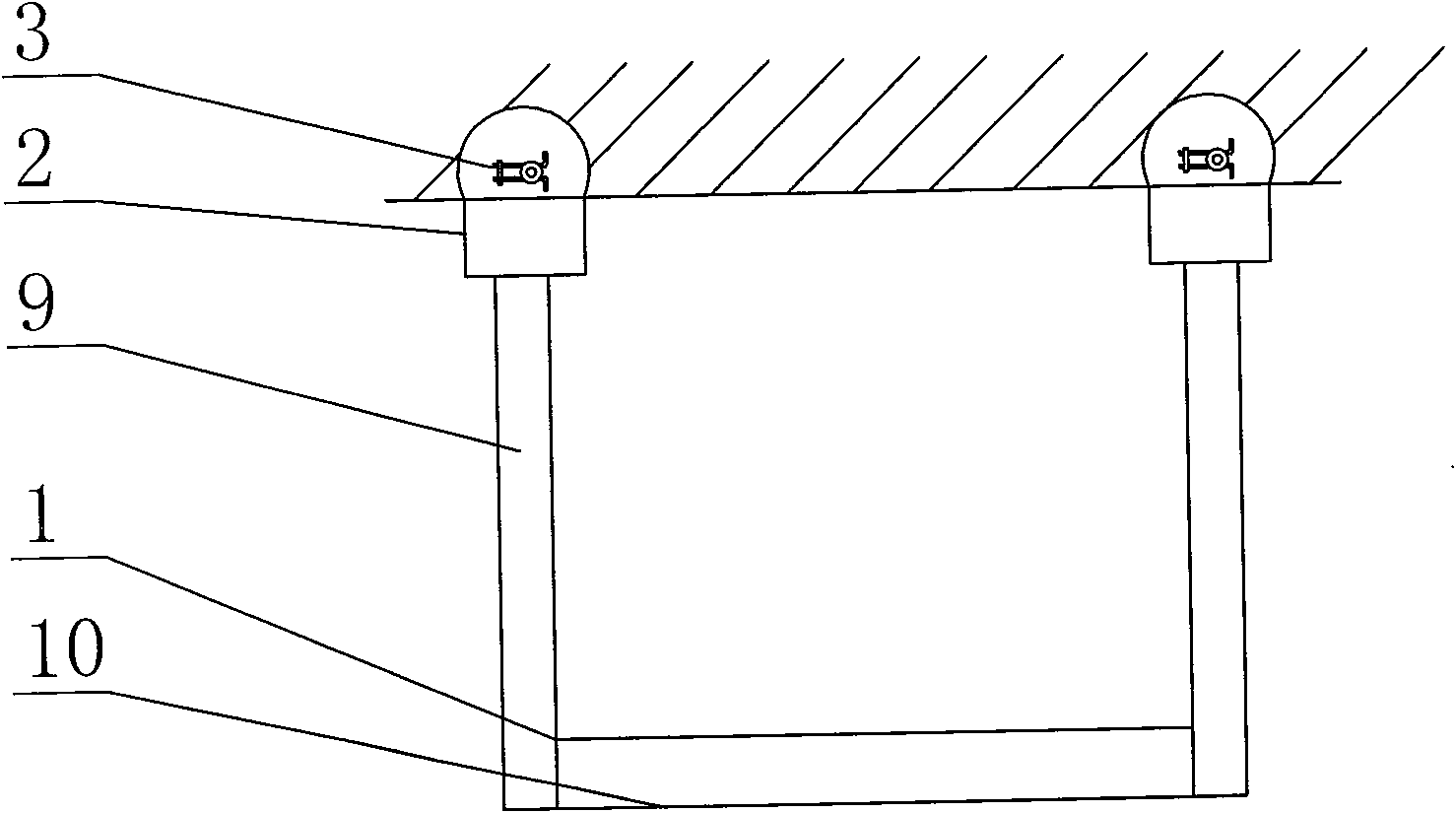

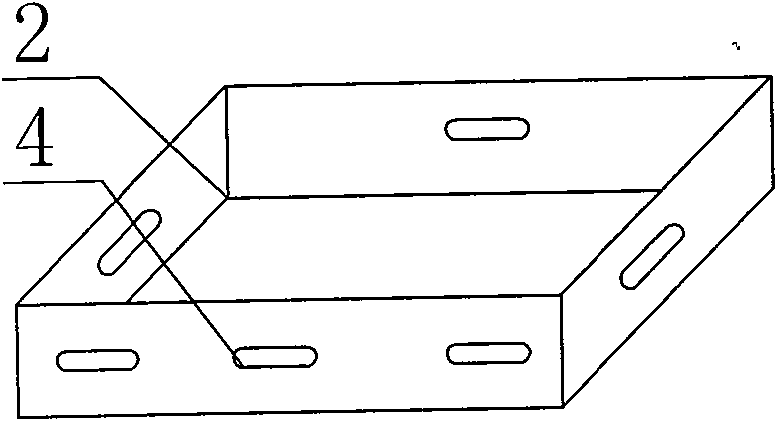

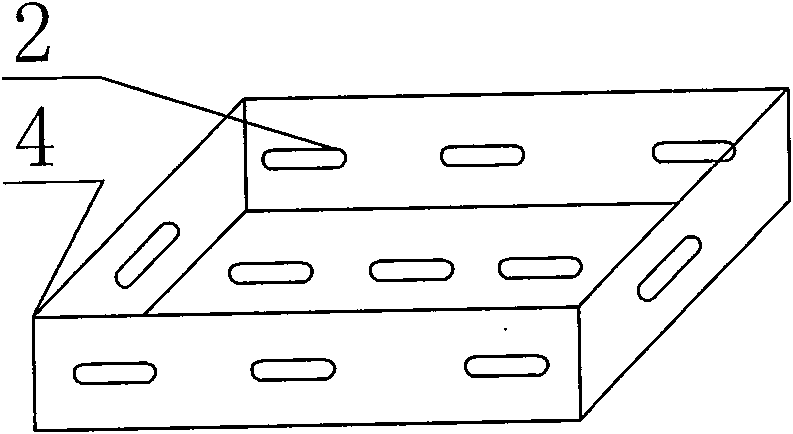

[0031] A cable tray strong connecting member, characterized in that: it is formed by connecting a pair of booms 9 and a cross arm 8 through fasteners to form a bracket 1, and a pair of connectors 2 fix the bracket 3 by fixing the implant 3. The bracket 1 is connected with the fixed wall. The connector 2 is a square cavity with a round hole 4 and one end closed. The fixed implant 3 is formed by two parallel threaded steel bars 5 to form a slideway 6. The middle of the slideway 6 is composed of a fixed bolt 8 that can slide between the two steel bars 5. One end of the two steel bars 5 is fixed together by an inverted U-shaped buckle 7. The cavity of the slideway 6 is filled with a molded lime sand gypsum core. One end of the root steel bar 5 is tilted upwards, and one end is symmetrically inverted L-shaped. The two steel bars 5 are arc-shaped. Flat steel, angle steel or steel plate are bent, the connector 2 is bent or welded from the plate, the oblong hole 4 on the connector 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com