Metal surface lacquer with flip-flop effect and its preparing method

A technology of changing color with angle and metal surface, which is applied in the field of metal topcoat with effect of changing color with angle and its preparation, and achieves the effect of enhancing anti-ultraviolet ability, improving weather resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

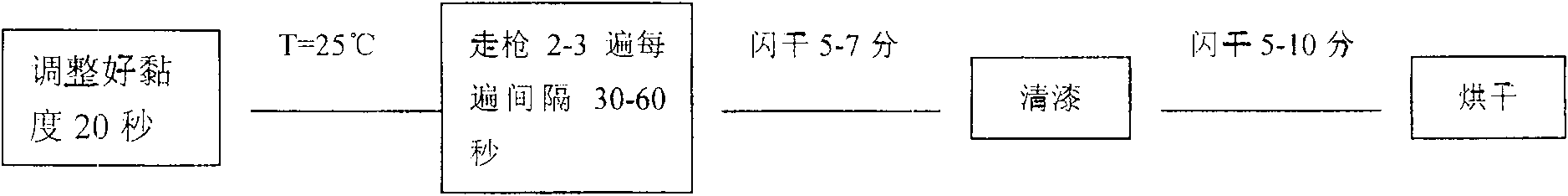

Method used

Image

Examples

Embodiment 1

[0046] Formula 1 for metallic finishes with flop effects

[0047] Ingredient parts by weight wt(%)

[0048] Nano particle dispersion 4.8

[0049] Setal173 (polyester resin) 21

[0050] Setamine138 (amino resin) 5.5

[0051] BI7982 (modified resin) 3.7

[0052] Metallux2154 aluminum powder) 3.5

[0053] CAB381-0.5 (aluminum powder directional agent) 4.7

[0054] Solvent 56

[0055] Auxiliary 0.8

[0056] The above formula is prepared according to the preparation method proposed by the invention, and a metal topcoat with a color-dependent effect can be obtained. The color-dependent effect of the coating (visual inspection): good, stone chip resistance: ≤2 grades, gloss (Gloss 20°) 97, Haze Hlog 95, artificial accelerated aging resistance time ≥ 1500 hours, other coating properties passed GB / T13492-92.

Embodiment 2

[0058] Metallic topcoat formulation with floppy effect 2

[0059] Ingredient parts by weight wt(%)

[0060] Nanoparticle dispersion paste 7.4

[0061] Desmophen 650 (polyester resin) 37

[0062] Setamine133 (amino resin) 21.3

[0063] Metallux2154 (aluminum powder) 1.3

[0064] CAB381-0.5 (aluminum powder directional agent) 3.3

[0065] Solvent 30.6

[0066] Auxiliary 1.1

[0067] The above formula is prepared according to the preparation method proposed by the invention, and a metal topcoat with a color-dependent effect can be obtained. The color-dependent effect of the coating (visual inspection): good, stone chip resistance: ≤2 grades, gloss (Gloss 20°) 95, haze (Haze Hlog) 127, artificial accelerated aging resistance time ≥ 1500 hours, good wear resistance of the coating, other coating properties passed GB / T13492-92.

Embodiment 3

[0069] Metallic topcoat formulation with floppy effect 3

[0070] Ingredient parts by weight wt(%)

[0071] Nano particle dispersion slurry 0.9

[0072] Desmophen 650 (polyester resin) 14

[0073] Setal173 (polyester resin) 12

[0074] Setamine133 (amino resin) 7.1

[0075] C1158 (amino resin) 2.6

[0076] Vestanat BI358A (modified resin) 6.9

[0077] SSP504-AR (aluminum powder) 7.7

[0078] CAB381-0.5 (aluminum powder directional agent) 2.5

[0079] CAB551-0.2 (aluminum powder directional agent) 4

[0080] Pearlescent Pigment 3

[0081] Solvent 36.9

[0082] Auxiliary 2.4

[0083] The above formula is prepared according to the preparation method proposed by the invention, and a metal topcoat with a color-dependent effect can be obtained. The color-dependent effect of the coating (visual inspection): good, stone chip resistance: ≤2 grades, gloss (Gloss 20°) 96, haze (Haze Hlog) 189, artificial accelerated aging resistance time ≥ 1500 hours, other coating properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com