Lightweight aggregate pretreatment method and its device

A pretreatment device and light aggregate technology, applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of inability to maintain free water in concrete mixture, poor pumpability of light aggregate concrete, light aggregate The problem of slow material pretreatment speed is solved, and the effect of improving pumping construction performance, improving pretreatment efficiency, and good workability of pumping is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Example: Preparation of Light Aggregate

[0019] Serial number

[0020] In this light aggregate pretreatment method, the light aggregate is shale ceramsite, clay ceramsite, natural pumice particles or natural vermiculite particles, which is characterized by the following steps:

[0021] Step 1, pre-wetting the light aggregate, putting the light aggregate into the container and adding water to make the water absorption rate of the light aggregate 60%-80%; the light aggregate pre-wetting is a pressurized pre-wetting method. The above-mentioned pressurized pre-wetting method is to put the light aggregate into a light aggregate concrete pretreatment device, which is a closed pressure vessel whose volume can be customized according to needs.

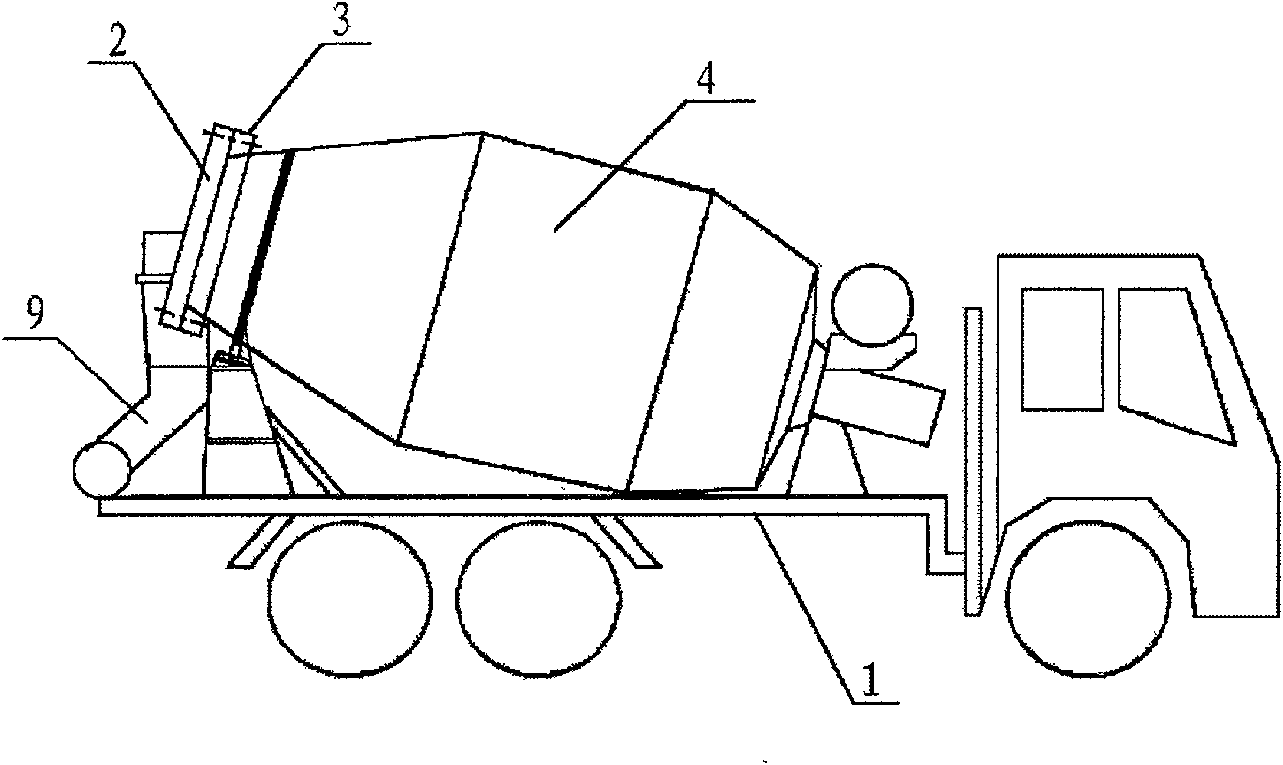

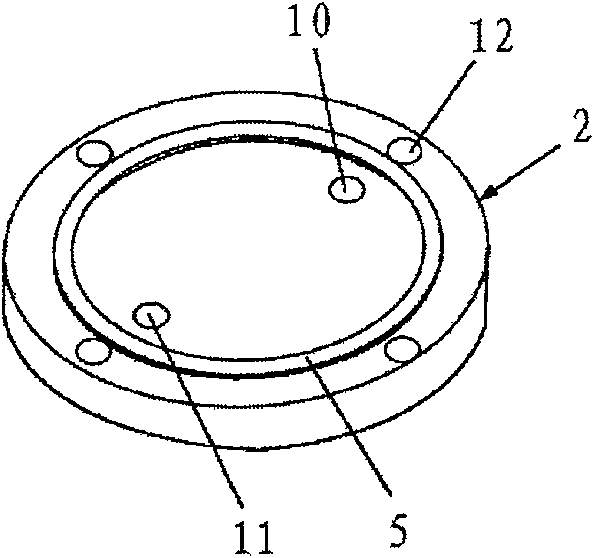

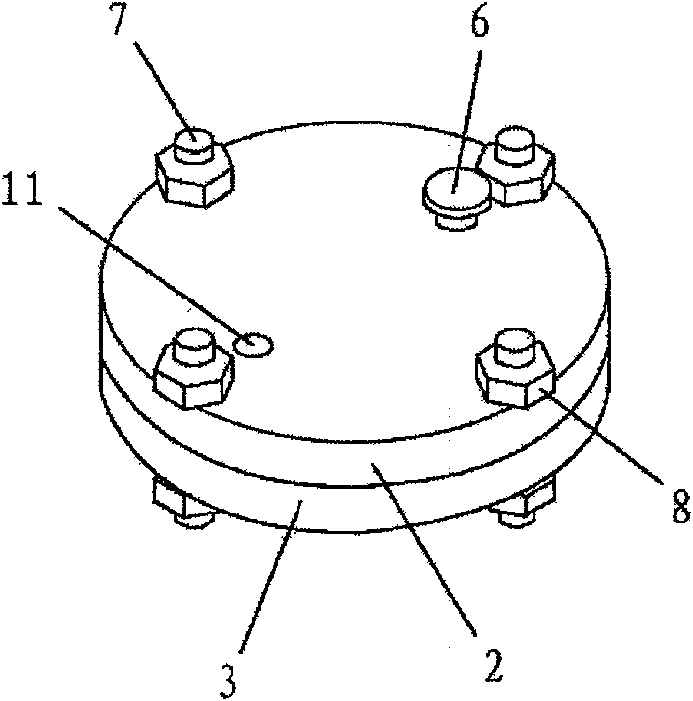

[0022] See Figure 1-3 The above-mentioned closed pressure vessel is in the shape of a tank, and the tank body 4 of the closed pressure vessel is supported on the chassis 1 of the concrete mixer truck. A ring plate 3 is welded aro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com