Corrosion inhibition antisludging agent special for ethylene compression system

A technology of corrosion and scale inhibitor and compression system, applied in the field of corrosion and scale inhibitor, can solve the problems such as difficulty in meeting the requirements of ethylene compression system, no report on corrosion and scale inhibitor, poor corrosion and scale inhibitor effect, etc. The effect of corrosion and scale inhibition is good, the effect of preventing scaling and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Make 100 grams of the corrosion and scale inhibitor of the present invention.

[0016] Add 68 grams of water and 0.4 grams of sodium hexametaphosphate to the container in turn, control the temperature between 50-90 ° C, stir until the sodium hexametaphosphate is completely dissolved, and after cooling to a suitable temperature, add 3.8 grams of imidazoline, 27.8 gram of ethylenediamine, fully stirred, reacted, cooled to room temperature, and filtered to obtain the product. After testing: the corrosion inhibition rate reaches 98.42%, the scale inhibition rate reaches 96.56%, the effect is remarkable, and it is superior to similar products.

Embodiment 2

[0017] Embodiment 2: making 100 grams of the corrosion and scale inhibitor of the present invention.

[0018] Add 71 grams of water and 0.5 grams of sodium hexametaphosphate to the container in turn, control the temperature between 50-90 ° C, stir until the sodium hexametaphosphate is completely dissolved, and after cooling to a suitable temperature, add 2.9 grams of imidazoline, 25.6 gram of ethylenediamine, fully stirred, reacted, cooled to room temperature, and filtered to obtain the product. After testing: the corrosion inhibition rate reaches 99.04%, the scale inhibition rate reaches 97.82%, the effect is remarkable, and it is superior to similar products.

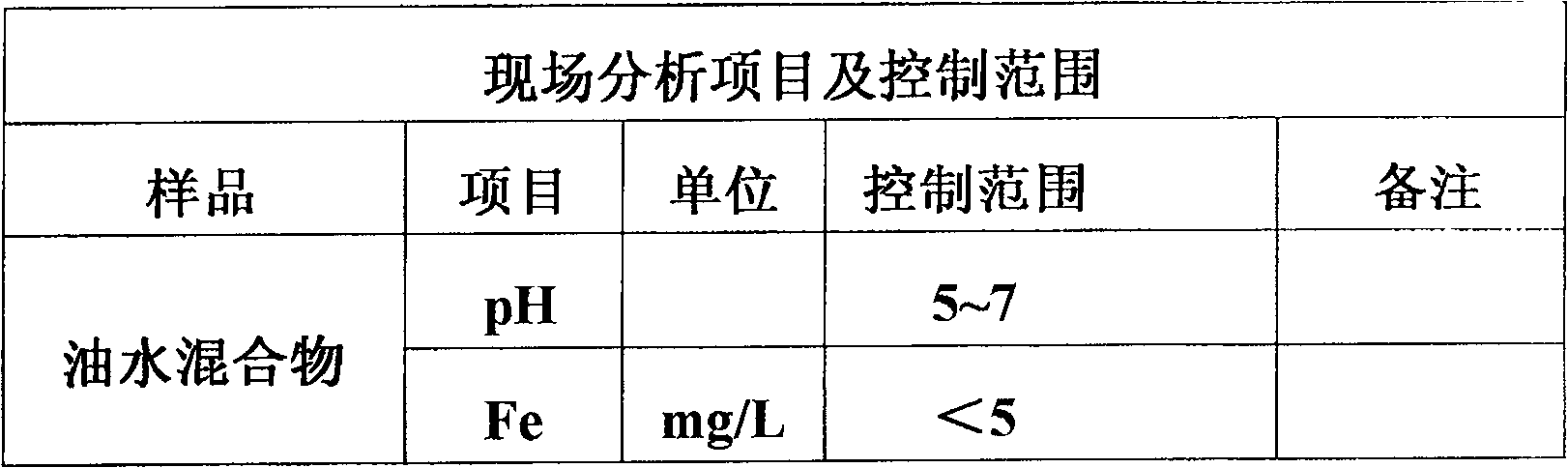

[0019] The using method of corrosion and scale inhibition of the present invention is: 1, set up reagent tank: set up volume > 3M 3 1. A reagent tank for containing the corrosion and scale inhibitor, which communicates with the reagent injection port through a pipeline, and injects the reagent with a reagent pump. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com