Ventilation device for internal combustion engine

A technology of a ventilator and an internal combustion engine, which is applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problem of lubricating oil sucking into the combustion chamber, and achieve the effects of long passage path, improved removal effect, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

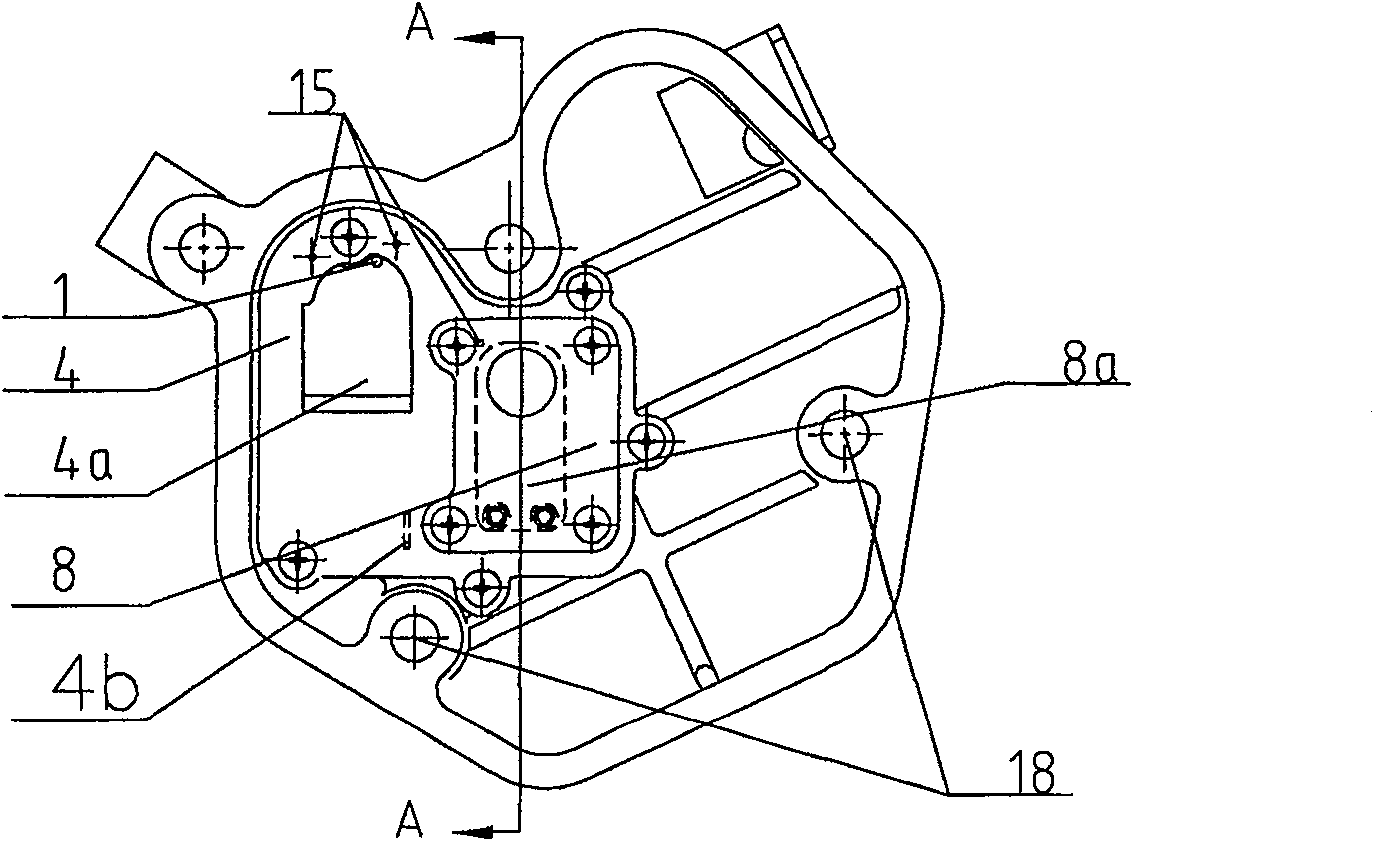

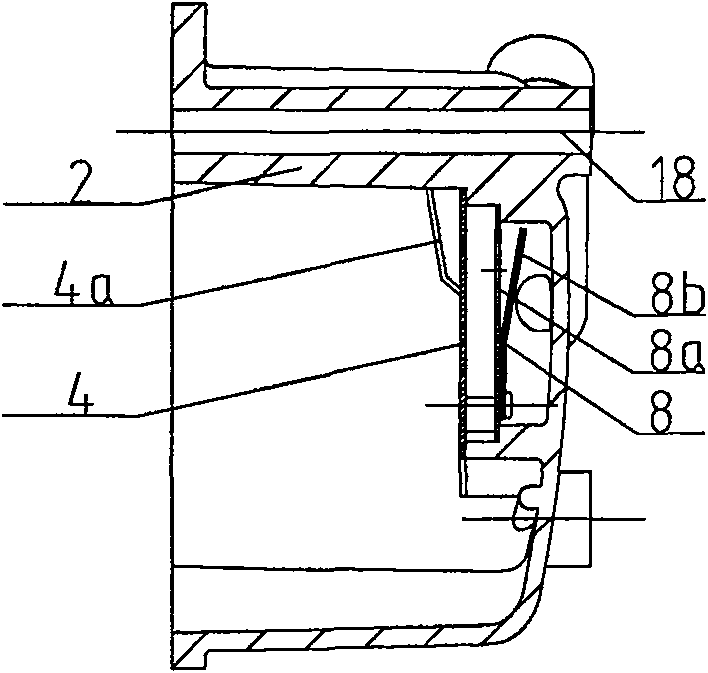

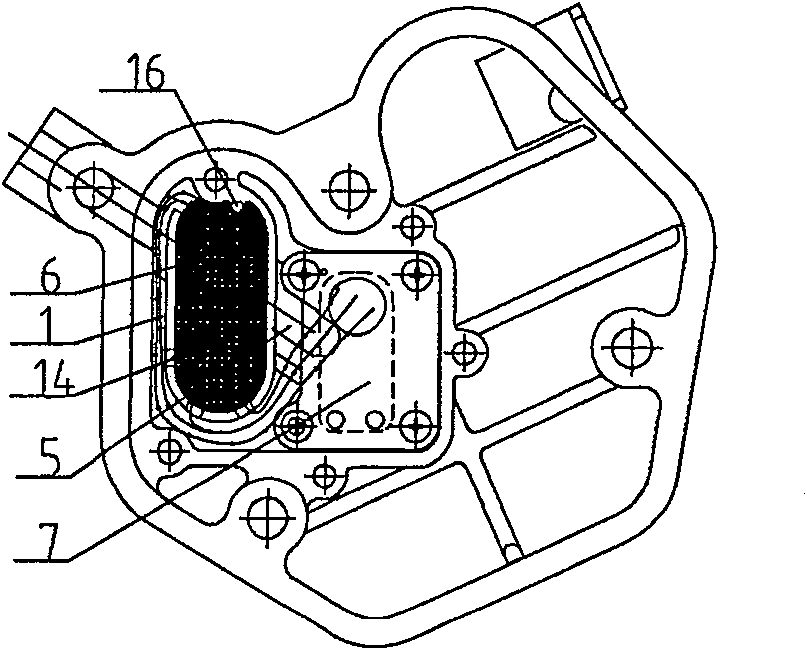

[0024] The present invention mainly consists of a cylinder head cover 1, a second cover plate 2, a rocker arm 3 for operating intake and exhaust valves, a first cover plate 4, a cavity 5, an oil-gas separation chamber 6, a control switch chamber 7, and a one-way valve component 8 (breathing shrapnel 8a, breathing sheet pressing plate 8b), pipeline system 9, cylinder head 10, intake manifold 11, filter screen 12, through hole 13, opening 14, oil drain hole 15, pillar 16, exhaust manifold 17, The cylinder head cover hole 18, the cavity 19 on the intake manifold and the rocker arm chamber 20 etc. are composed.

[0025] Such as Figure 1 ~ Figure 4 Shown: the present invention comprises a cylinder head cover 1, and a rocker arm 3 for operating intake and exhaust valves is included in the cylinder head cover 1. In the cylinder head 10 are provided an inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com