Mechanical equipment fault on-line diagnostic equipment and method

A technology for mechanical equipment and diagnostic devices, applied in electrical testing/monitoring, etc., can solve the problems of large size, high power consumption, poor anti-interference performance, etc., and achieve the effect of strong anti-interference, low power consumption and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

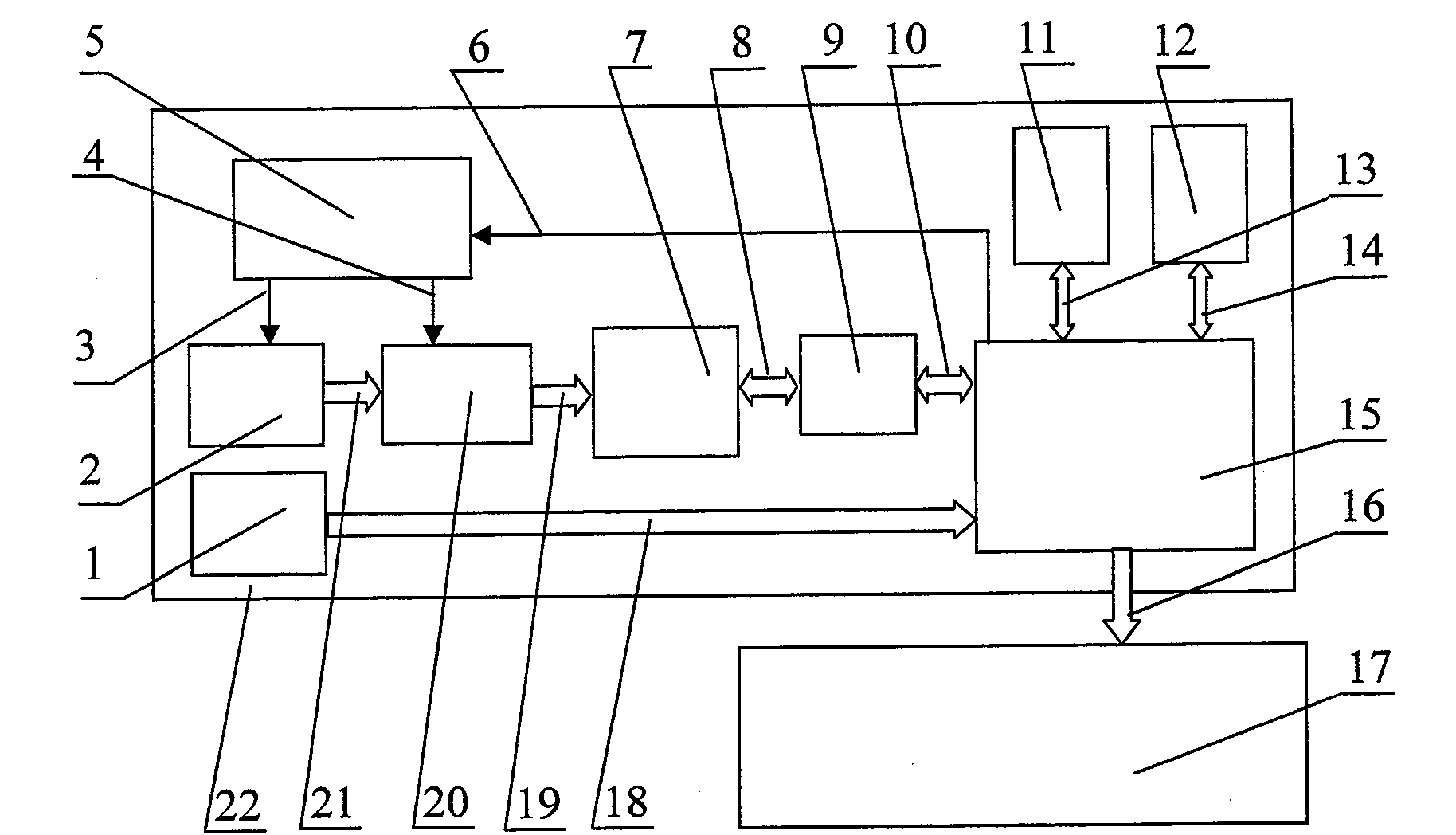

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0012] In the embodiment, the analog-to-digital conversion chip 2 whose model is AD7656AST is connected with the first-in-first-out memory chip 20 whose model is IDT72V235L15PF; The memory chip 20 is connected to control high-speed data acquisition; the microprocessor chip 15 of ARM9-S3C2440 is connected to the complex programmable logic device chip 5 to start data acquisition; the digital signal processing chip 7 of ADSP-TS201S is connected with the first-in-first-out Memory chip 20 links to each other, reads the data that collects; Digital signal processing chip 7 links to each other with microprocessor chip 15 through the dual-port RAM chip 9 that model is IDT70V24, carries out data exchange; Model is that the analog-digital conversion chip 1 of MAX1290ACEI and micro Processor 15 links to each other, transmits the data collected at low speed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com