Test device and method of laser induced piston heat fatigue

An experimental device and thermal fatigue technology, applied in measurement devices, thermal analysis of materials, testing of machine/structural components, etc., can solve the problems of long experimental period, inability to test piston laser-induced thermal fatigue, uncontrollable heating area, etc. Short experimental period, easy parameter setting, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

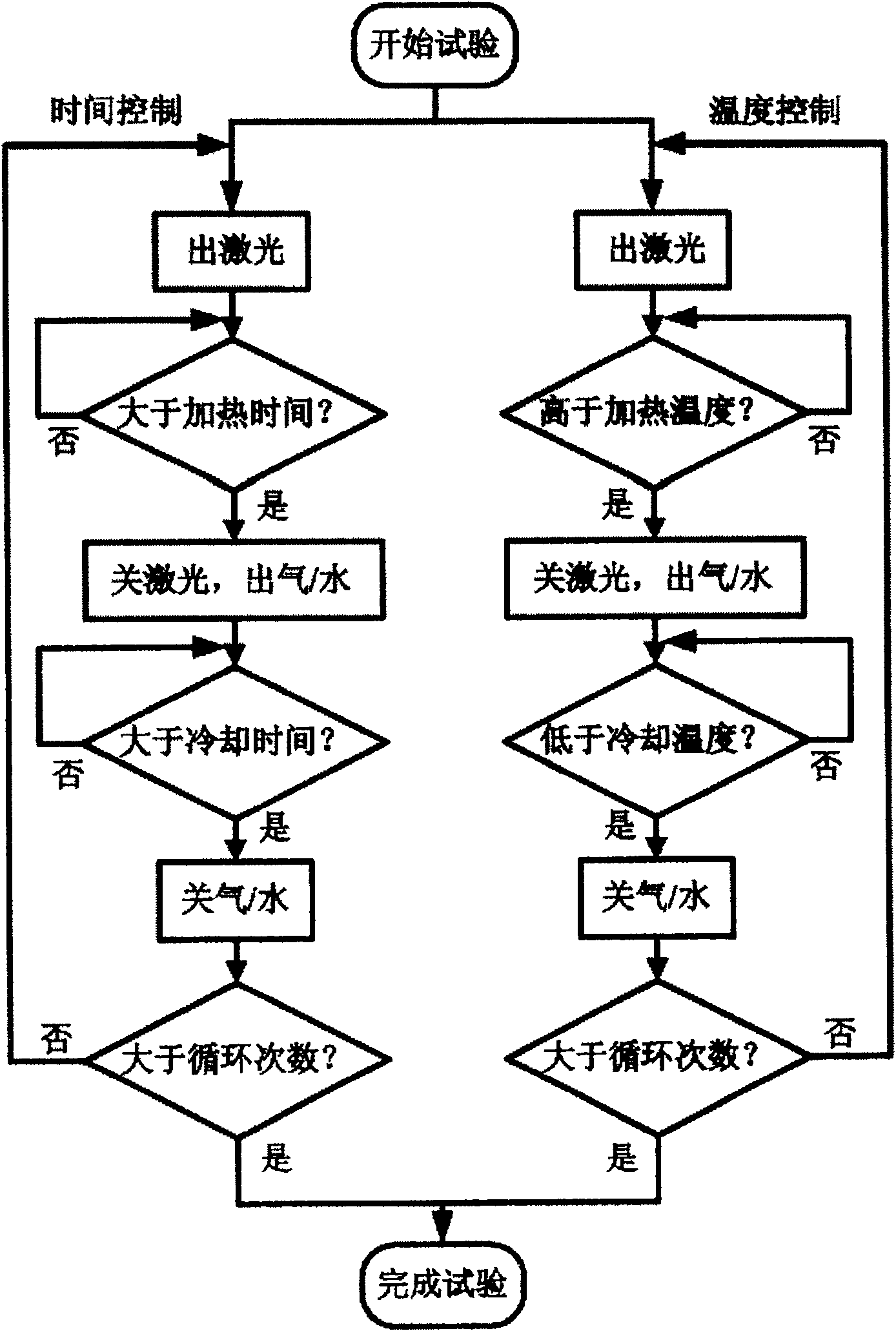

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

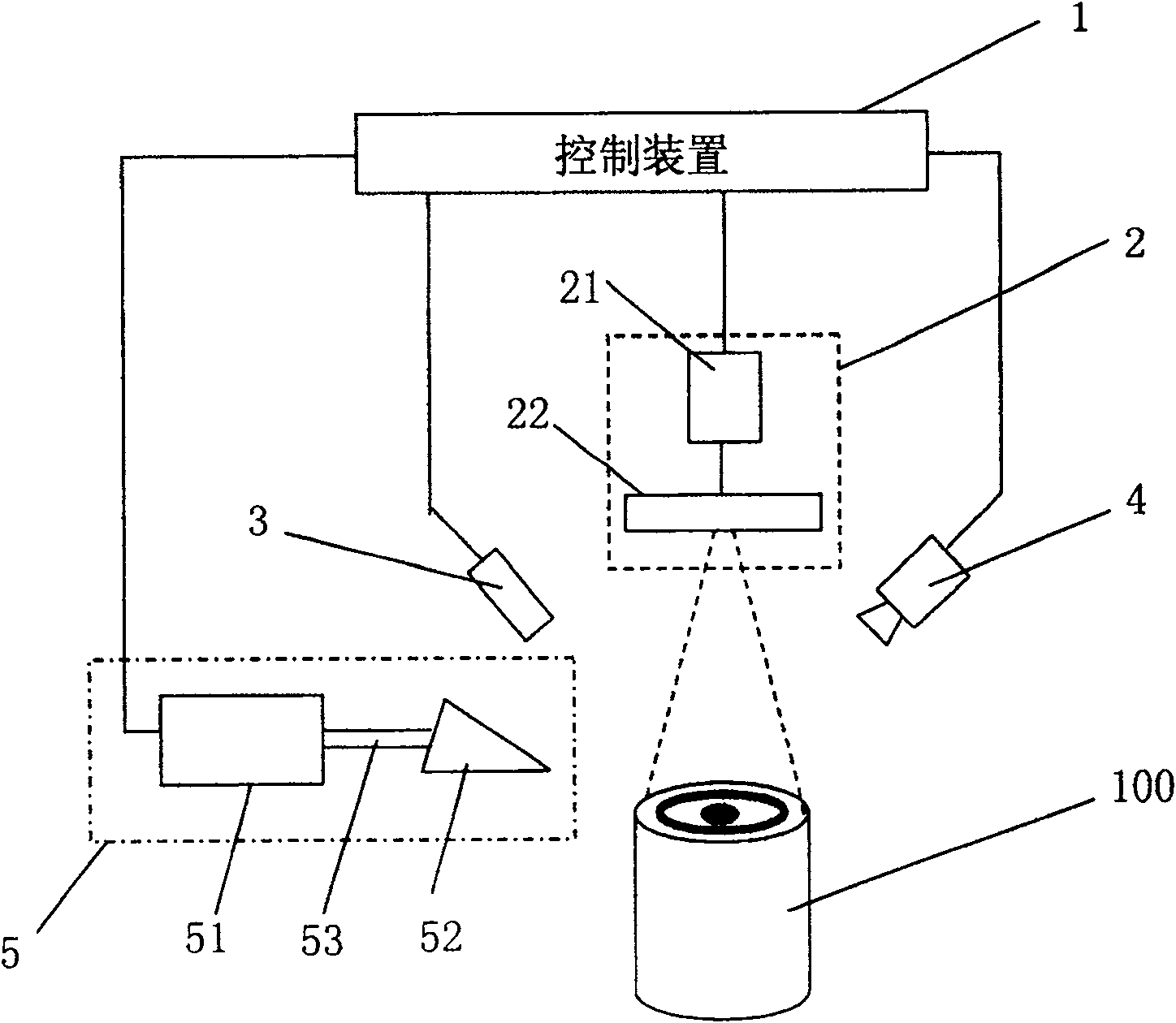

[0043] like figure 1 As shown, the laser-induced piston thermal fatigue experimental device of the present invention was made.

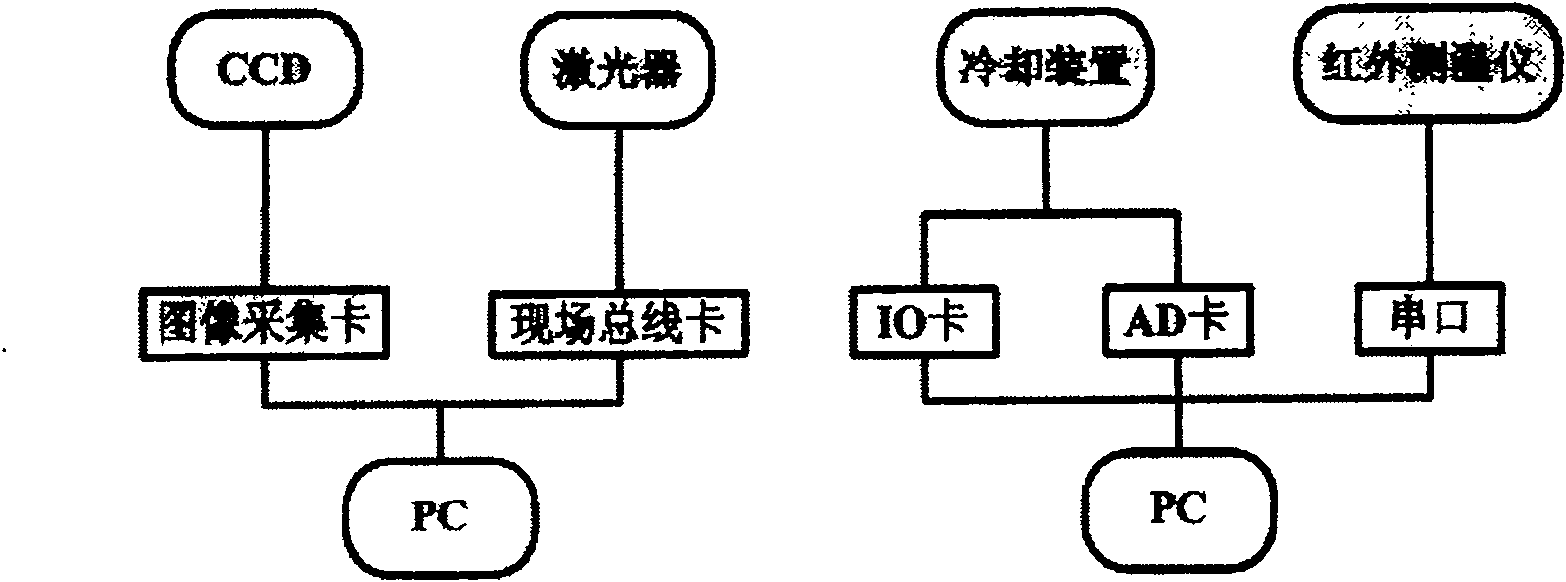

[0044] Wherein, the control device 1 includes an image acquisition card, an IO card, a PROFIBUS field bus card and two PCs.

[0045]The heating device 2 mainly includes a laser 21 and a beam shaper 22 . In this embodiment, the HL 3006D industrial Nd-YAG continuous laser produced by HAAS Company of Germany is used, and the maximum power is 3000W. The built-in Winlas software can control the laser 21 through the network cable, and also supports the development of control software based on the Profibus-DP protocol. The light output time and intensity of the laser 21 are controlled by the control device 1 . The laser device 21 that this embodiment selects supports Profibus-DP, the present invention adopts the linear ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com