Modified four-section water-feeding A/O deep denitrogenation device and process control method

A technology for deep denitrification and control methods, which is applied in water treatment parameter control, chemical instruments and methods, biological water/sewage treatment, etc. It can solve the problem of limited total nitrogen removal rate, high requirements for deep denitrification control, and high operating costs. problems, to achieve the effect of reducing TN removal rate, reducing carbon source dosage, and avoiding control failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

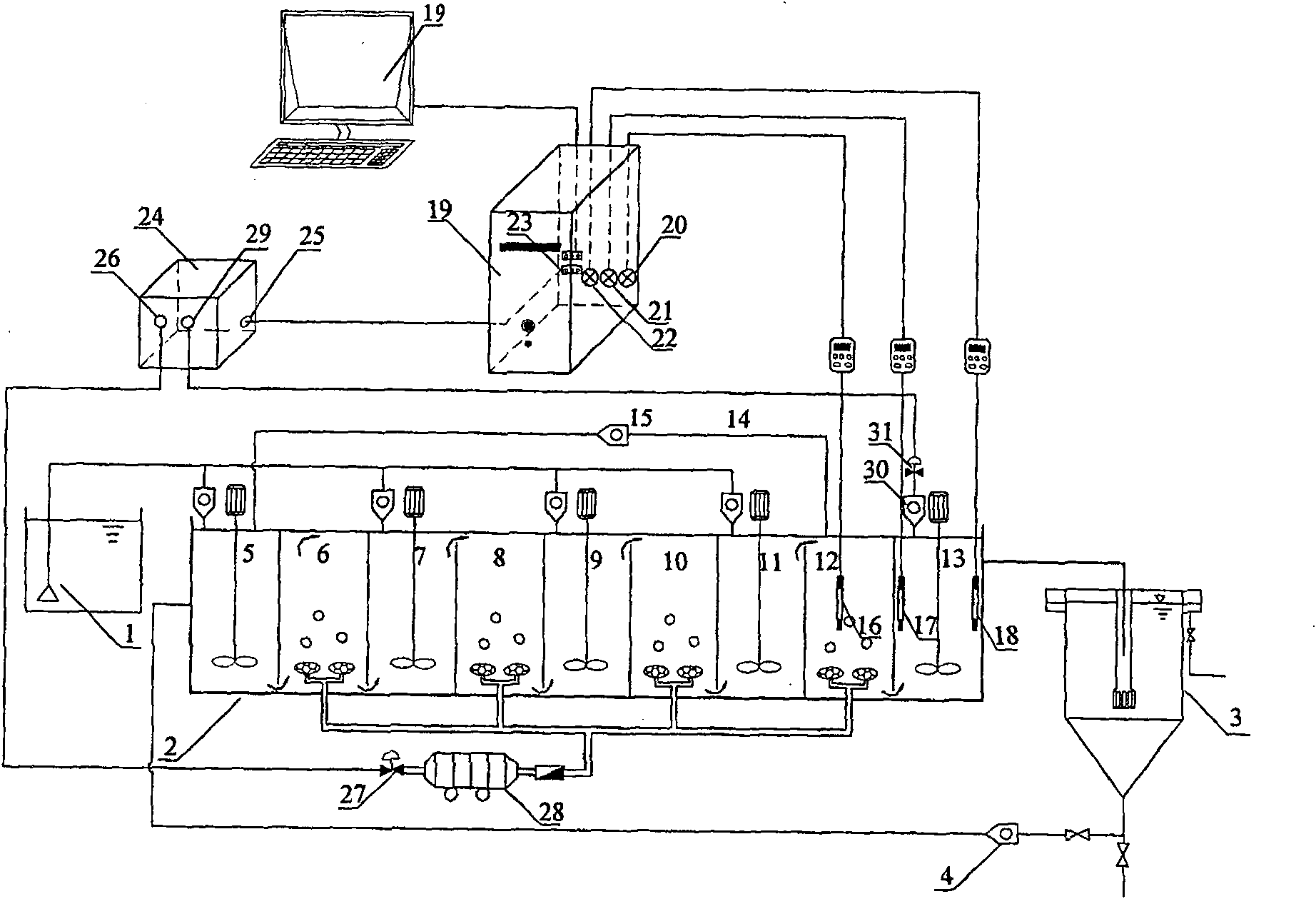

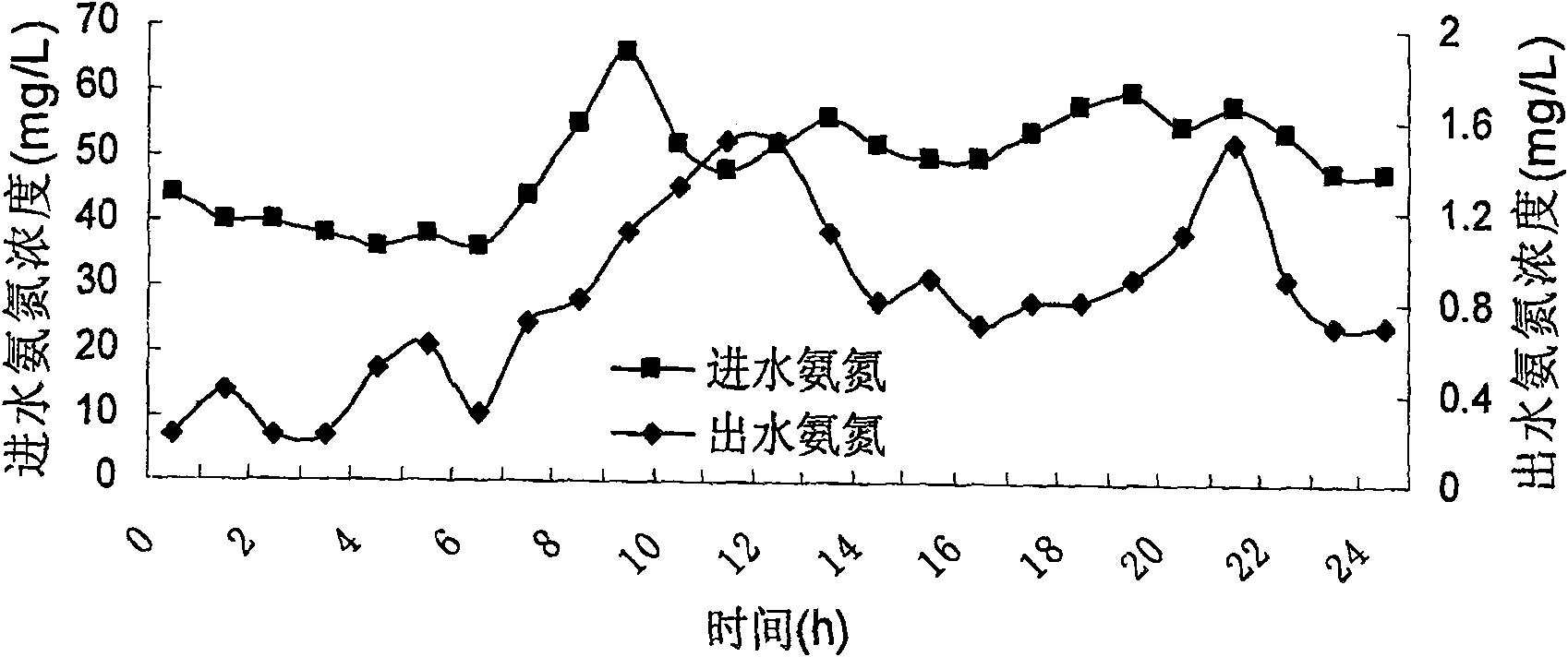

[0032] The actual domestic sewage discharged from a family area of a university was used as the experimental object (COD=220~350mg / L, TN=44~75mg / L). The multi-stage influent A / O bio-denitrification reactor used dissolves 320L, adopts four-stage improved A / O process, each stage has a volume of 80L, and dissolves 30L in the anoxic zone of the first, second, and third stages, and dissolves 30L in the aerobic zone. The solution volume is 50L; the anoxic zone in the fourth section is 30L, the aerobic zone is 40L, and the volume of the post-anoxic zone is 10L. Install nitrate nitrogen internal circulation facilities in the fourth aerobic zone. The system is equipped with 1 air compressor, the maximum air volume is 8m 3 / h, the minimum air volume is 0. The reactor is first subjected to sludge cultivation and domestication. After the domestication, the sludge concentration in each section is: 5-5.5g / L in the first section, 4-4.5g / L in the second section, and 2.8-3.2g / L in the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com