Liner making technique for casting lander of blast furnace with single iron notch, and free from baking casting material for iron notch

A technology for blast furnace iron tapping and iron trough castables, which is applied in the direction of discharge devices, etc., to achieve the effects of improving economic benefits, reducing labor intensity, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

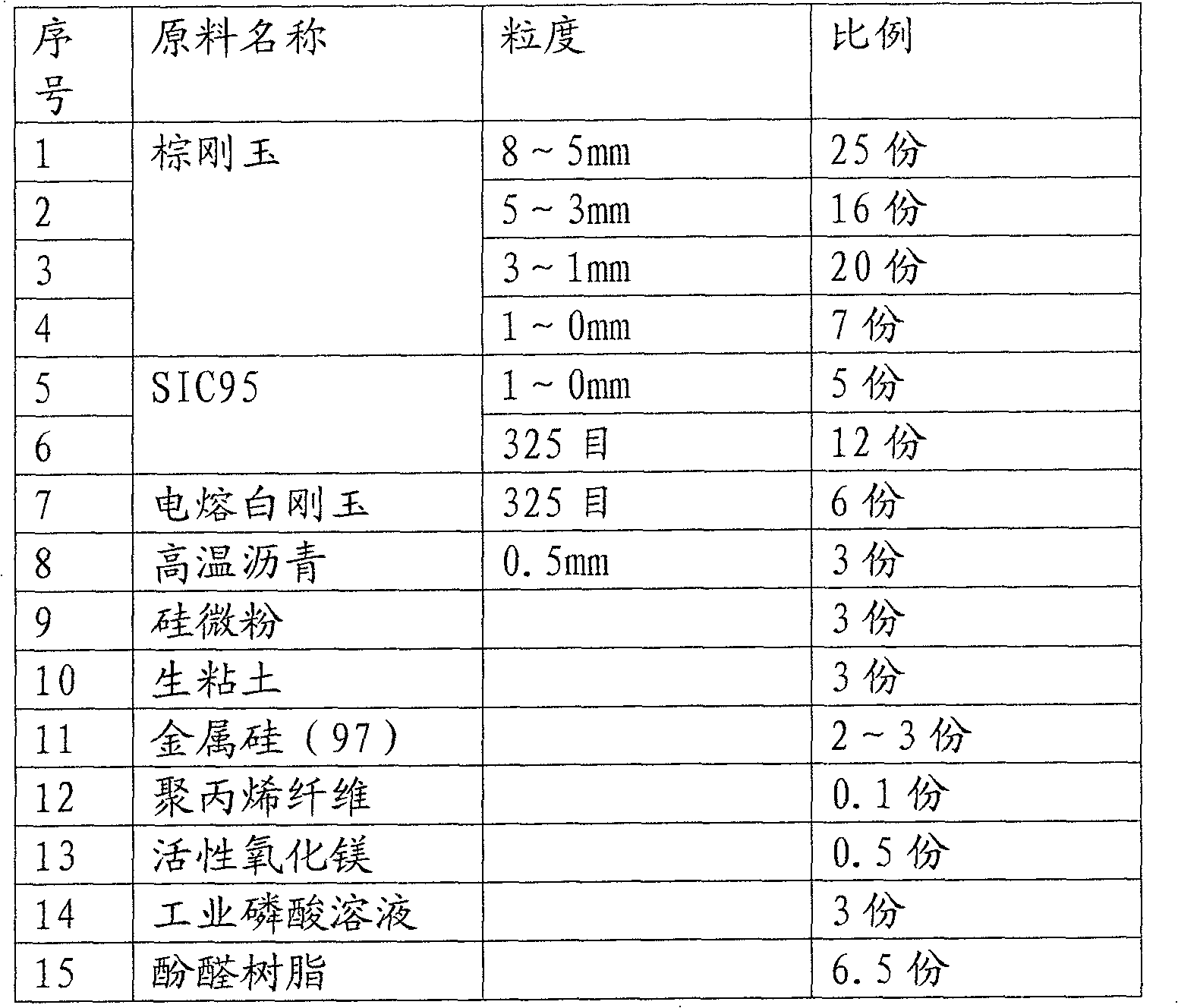

[0067] For a volume of 500m 3 ~1000m 3 Between blast furnaces, the material ratio for main ditch pouring is as follows:

[0068]

[0069] The first 13 materials in the above ingredients are mixed evenly to form a premix for later use. When in use, the premix is mixed with the industrial phosphoric acid solution and phenolic resin referred to in items 14 and 15 to form a mortar for pouring.

[0070] The process of using non-baking iron ditch castables for iron ditch lining is as follows:

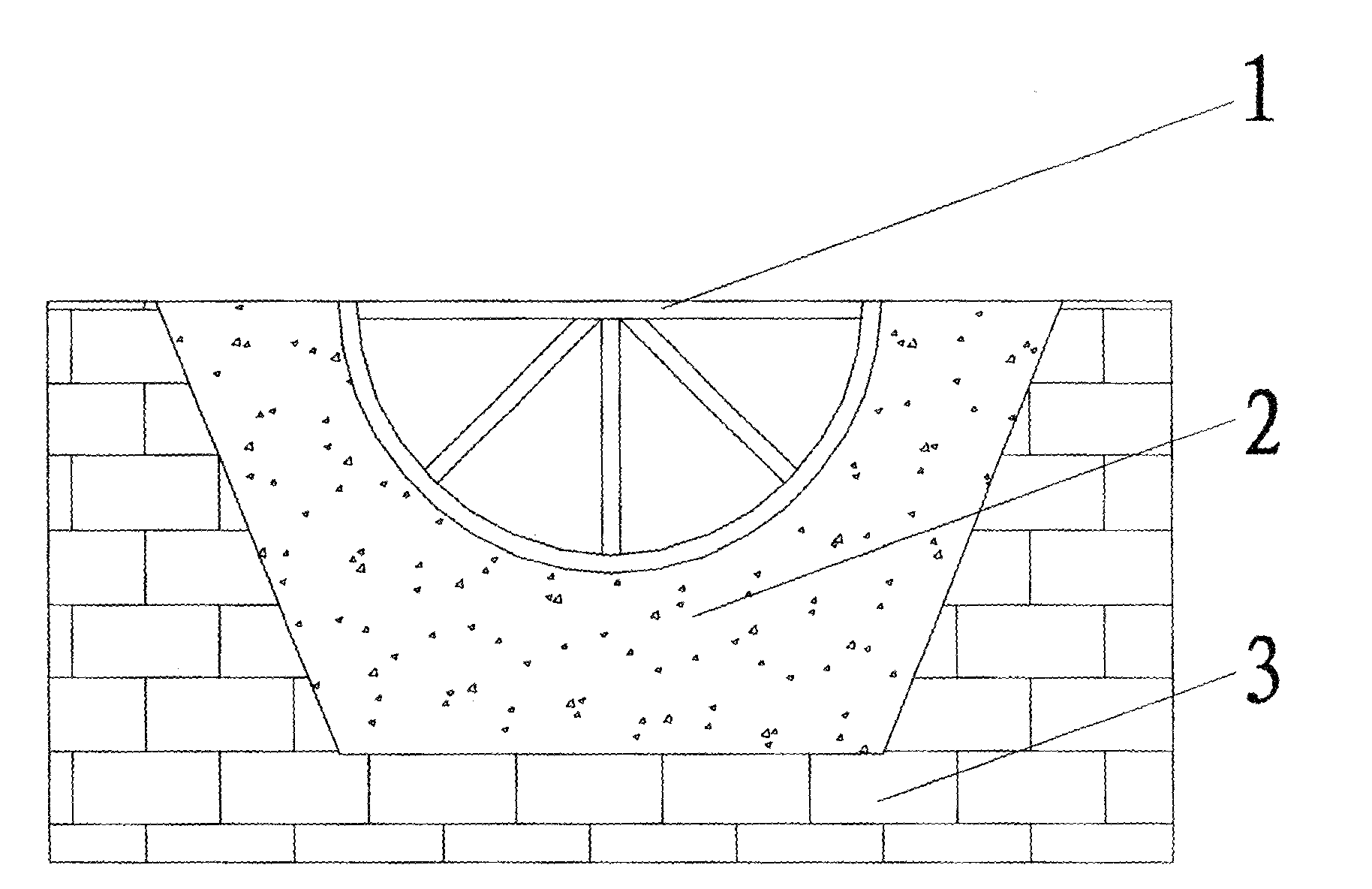

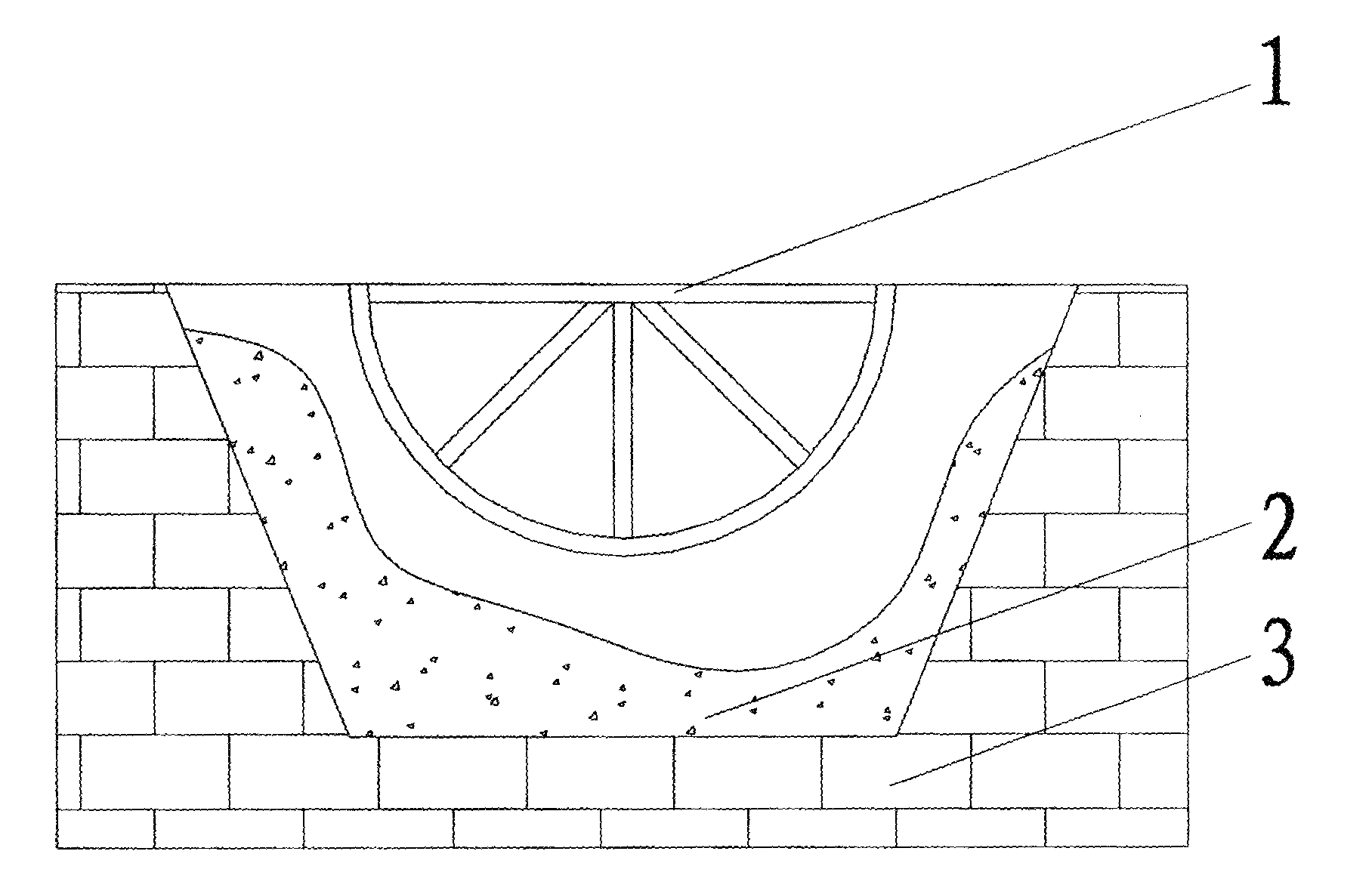

[0071] The cross-section of the iron ditch is shown in figure 1 shown. figure 1 Among them, 1 is the formwork, 2 is the non-baking main ditch castable, and 3 is the permanent refractory brick at the bottom of the ditch.

[0072] When pouring iron trenches, first clean up the residue at the bottom of the trench; support the mold in advance (wooden mold or steel mold, the inner wall of the formwork should be pre-brushed with engine oil to facilitate demoulding), and then put the mixed ...

Embodiment 2

[0080] For a blast furnace with a volume of 500m 3 For the following blast furnaces, the material ratio for main ditch pouring is as follows:

[0081]

[0082] The first 13 materials in the above ingredients are mixed evenly to form a premix for later use. When in use, the premix is mixed with the industrial phosphoric acid solution and phenolic resin referred to in items 14 and 15 to form a mortar for pouring.

[0083] The process of using non-baking iron ditch castables for iron ditch lining is as follows:

[0084] The cross-section of the iron ditch is shown in figure 1 shown. figure 1 Among them, 1 is the formwork, 2 is the non-baking main ditch castable, and 3 is the permanent refractory brick at the bottom of the ditch.

[0085] When pouring iron trenches, first clean up the residue at the bottom of the trench; support the mold in advance (wooden mold or steel mold, the inner wall of the formwork should be pre-brushed with engine oil to facilitate demoulding), an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com