Plasma uniformity control by gas diffuser

A gas dispersion and plasma technology, applied in electrical components, gaseous chemical plating, coatings, etc., can solve problems such as poor center thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

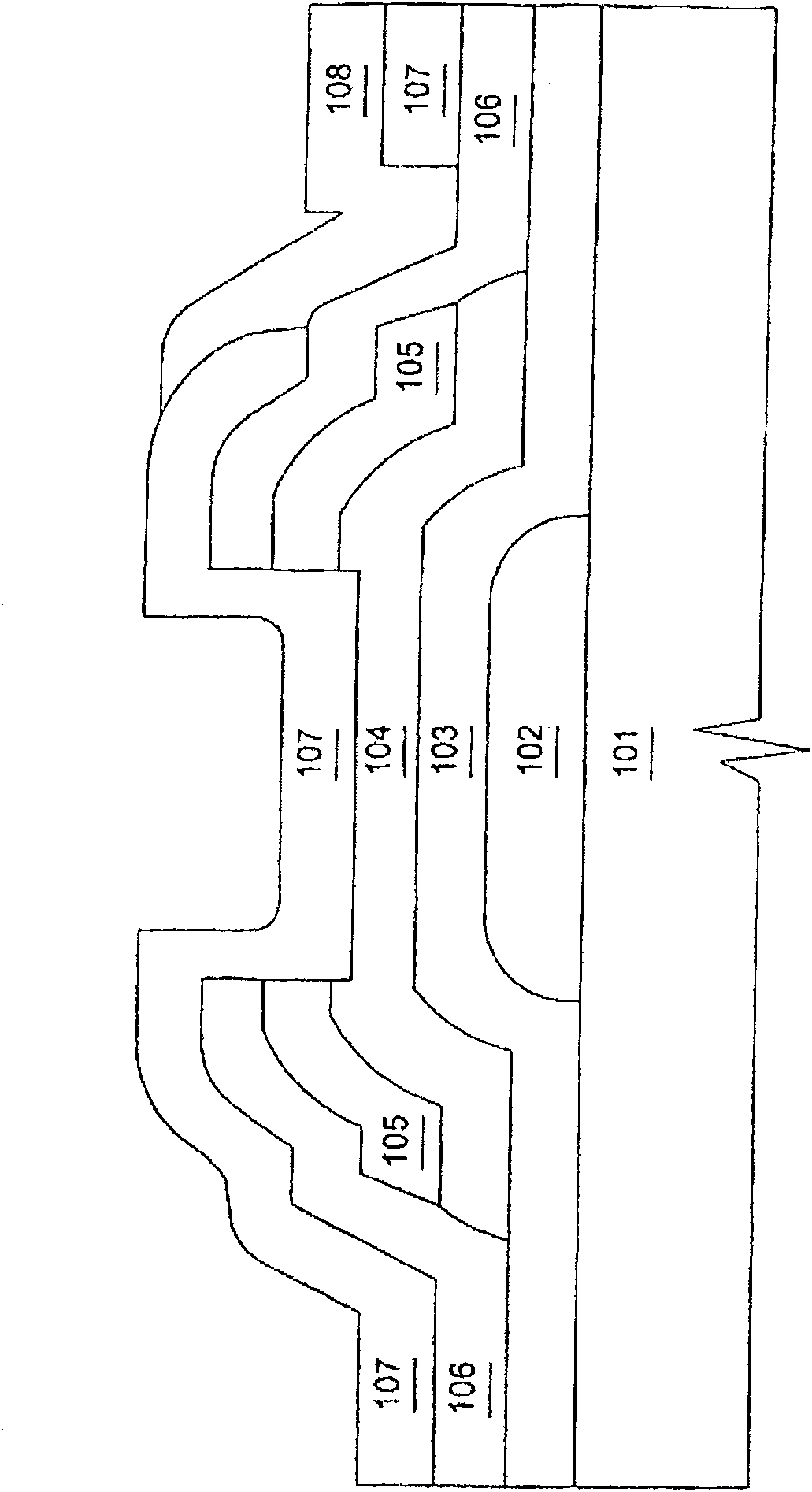

[0092] The present invention generally provides a gas distribution assembly for providing gas delivery within a processing chamber. The present invention will be described below in terms of a plasma-enhanced chemical vapor deposition system for processing large area substrates, such as that available from Applied Materials, Inc. Division AKT of Santa Clara, California, USA ( PECVD) system. However, it must be understood that the present invention can be applied to other configurations (such as etching systems), other chemical vapor deposition systems, and other systems that require the distribution of gas within the processing chamber, including systems that process circular substrates.

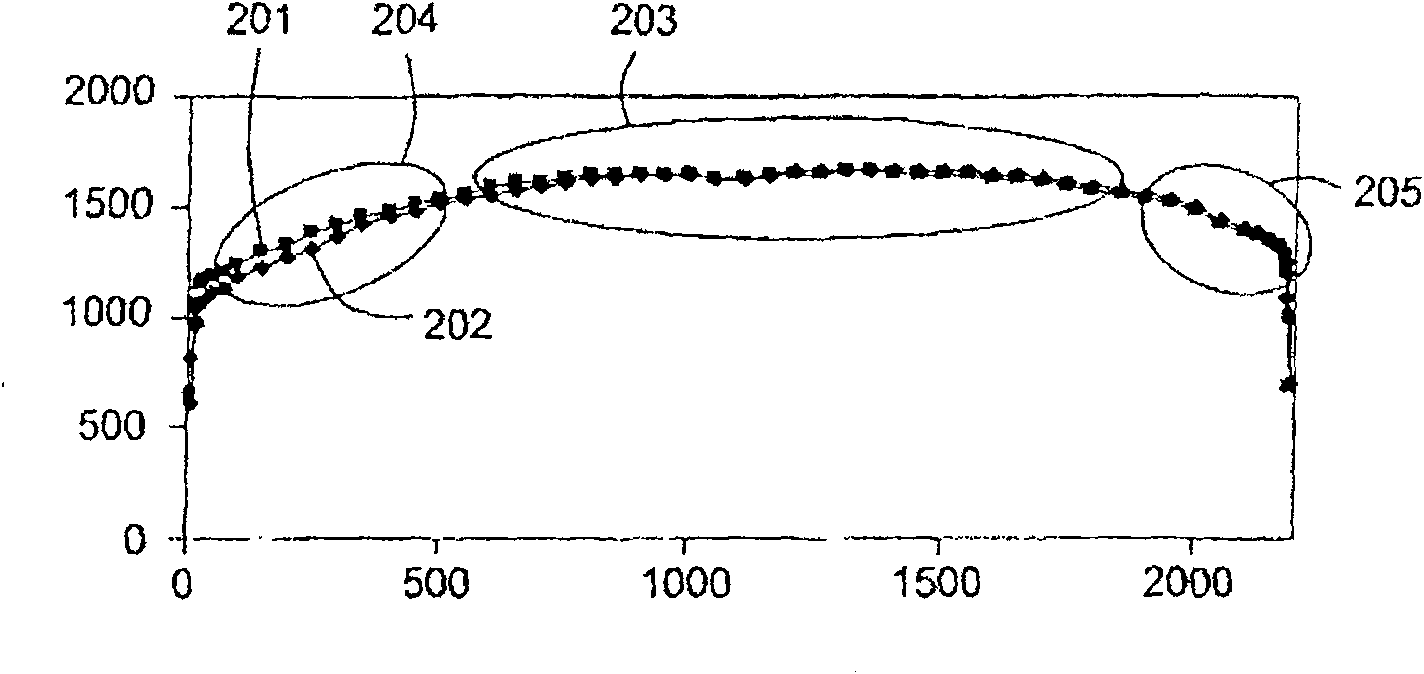

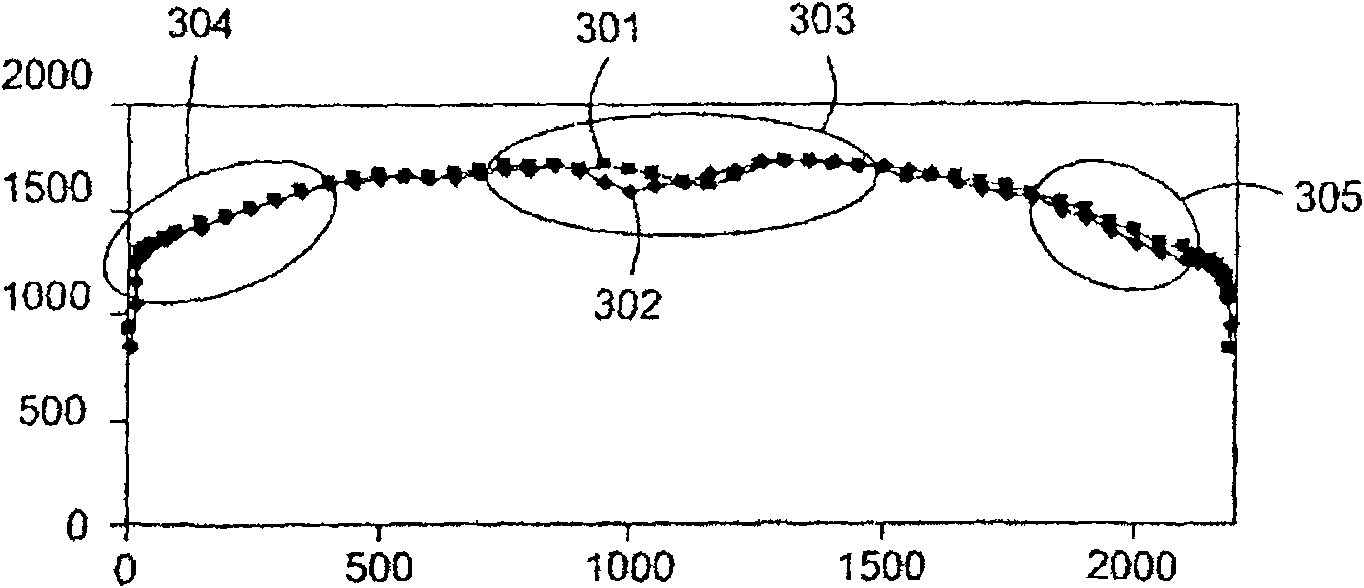

[0093] For silicon nitride films, the central thickness uniformity issue has been addressed by varying the size and / or distribution of the cathode cavities on the downstream surface of the PECVD gas diffuser plate. The cathode cavity enhances plasma ionization in the PECVD chamber. Because ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com