Production method for series of biologic compound fertilizer from deep processing dreg of marsh

A compound fertilizer and production method technology, applied in the direction of organic fertilizer preparation, organic fertilizer, bio-organic part treatment, etc., to achieve the effect of loose aggregate structure, good fertilization effect and high investment benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

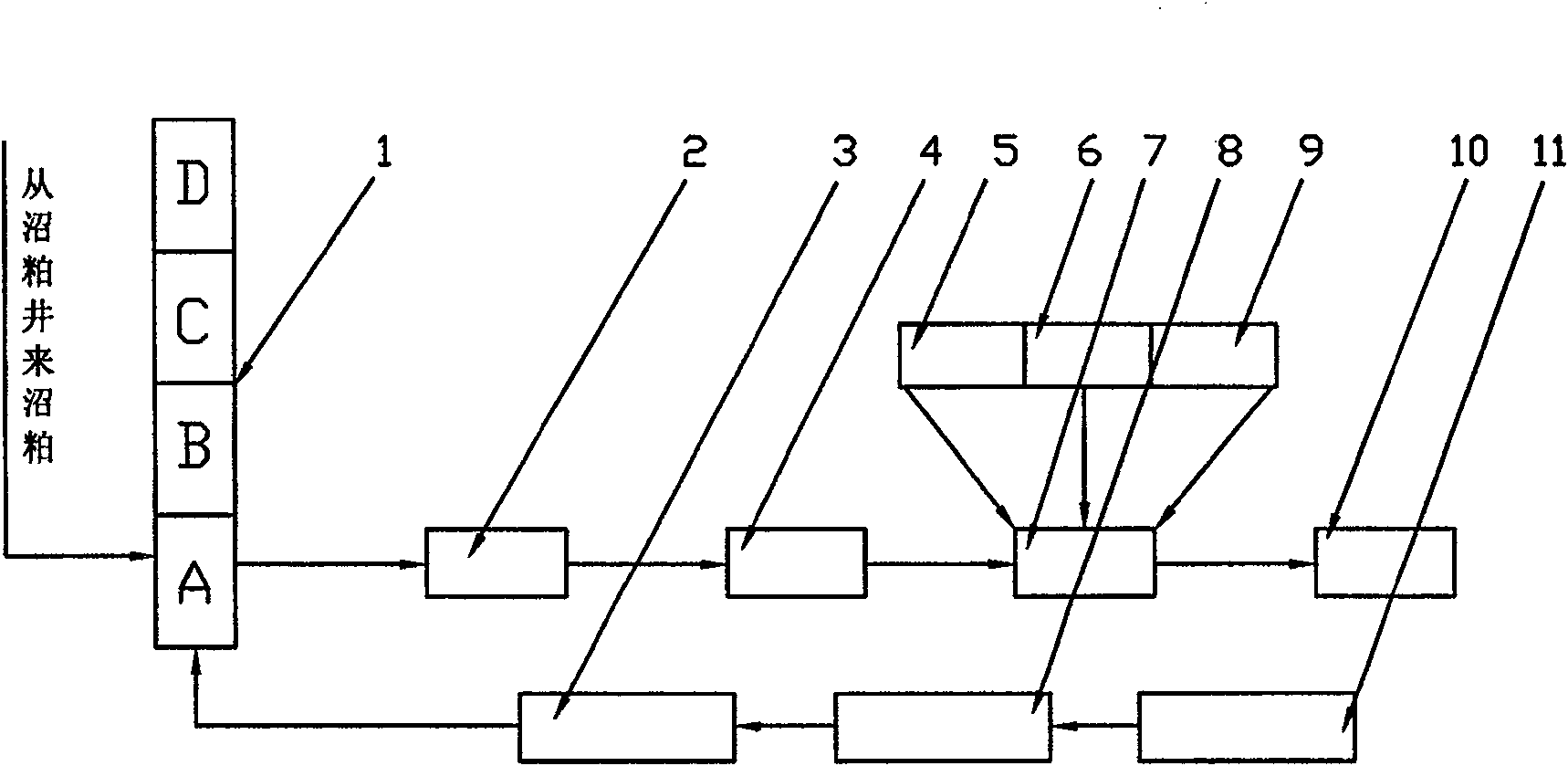

[0013] A production method for the production of a series of biological compound fertilizers through the deep processing of biogas dregs, using a three-stage multi-microbial biochemical enzyme system modulation method, that is: the first, second, and third-stage culture medium is continuously expanded and expanded to expand the multi-population microbial strain community to produce enzymes for deep processing biogas The method of the meal, the first-level medium adopts whole grains and miscellaneous grains to carry out single-species culture of multiple microorganisms as the first-level production mother bacteria for standby; the second-level medium uses sugar filter mud, which can also be replaced by poultry farm feces, and the first-level multi-population Microbial production mother bacteria are put in, and mixed piles are fermented at high temperature for 30-60 days, and the secondary production mother strain community carrier is obtained for use; High-grade multi-population...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com