Process for producing glucal

A technology of glucosinolate and glucose, which is applied in the direction of organic chemistry, can solve the problems of cumbersome operation, high cost, and low yield, and achieve the effects of shortening the process flow, low cost, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

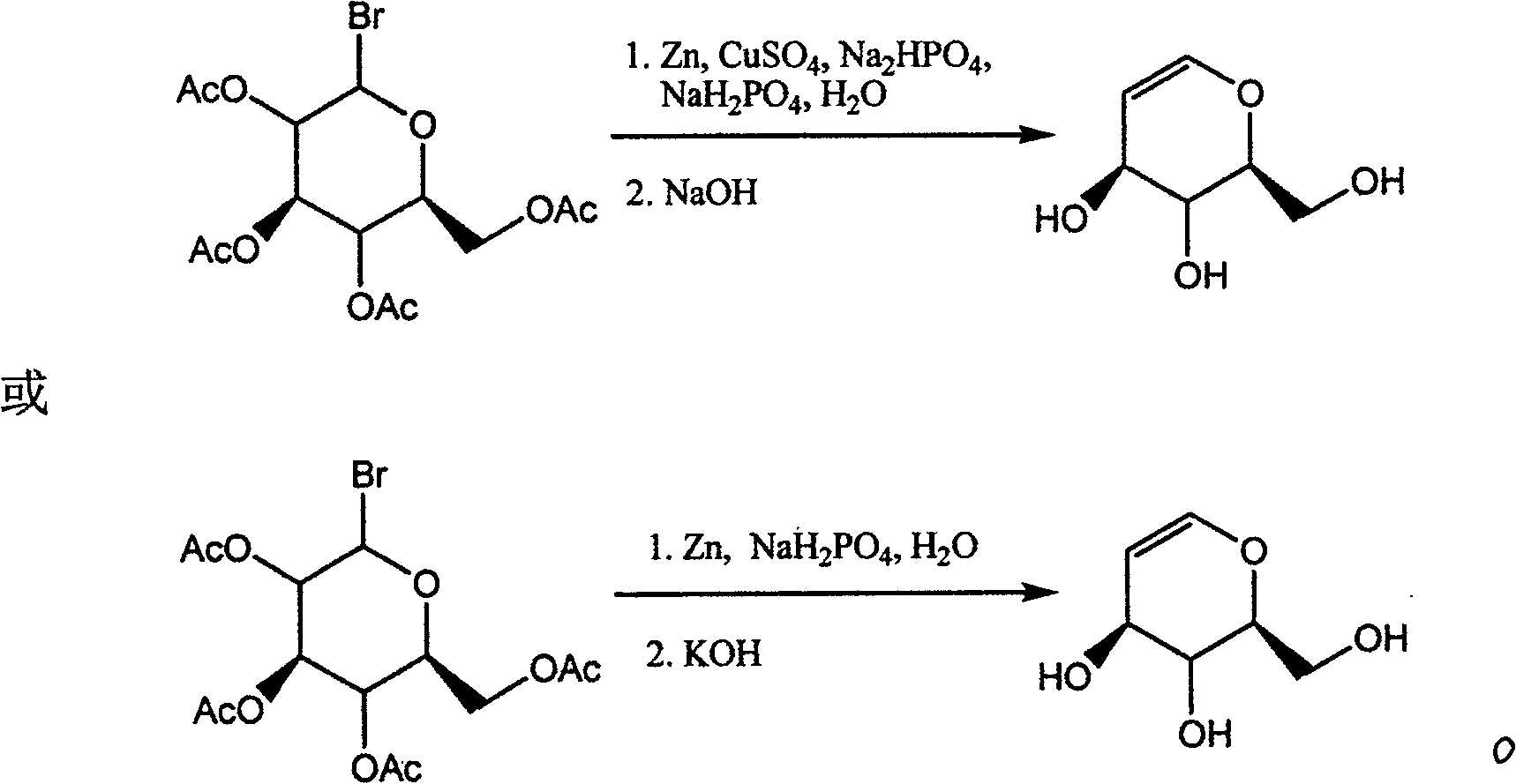

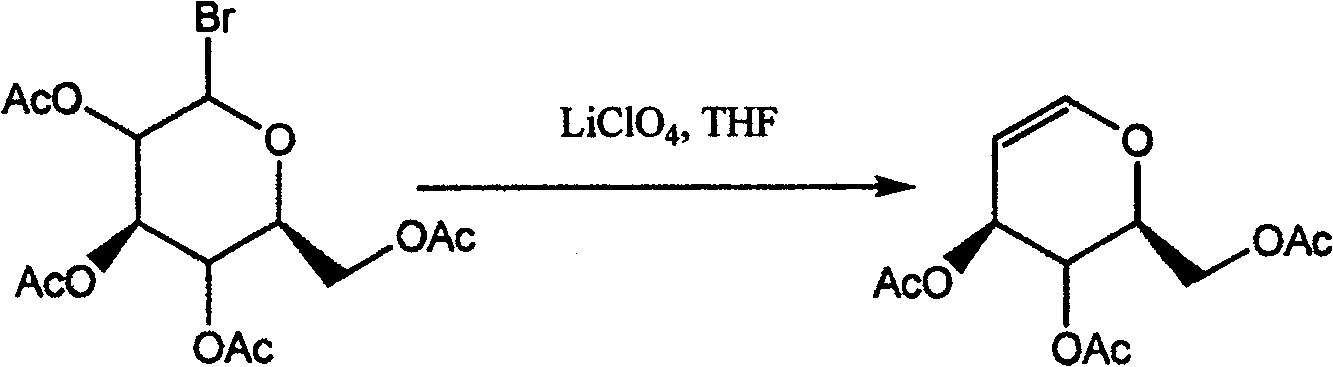

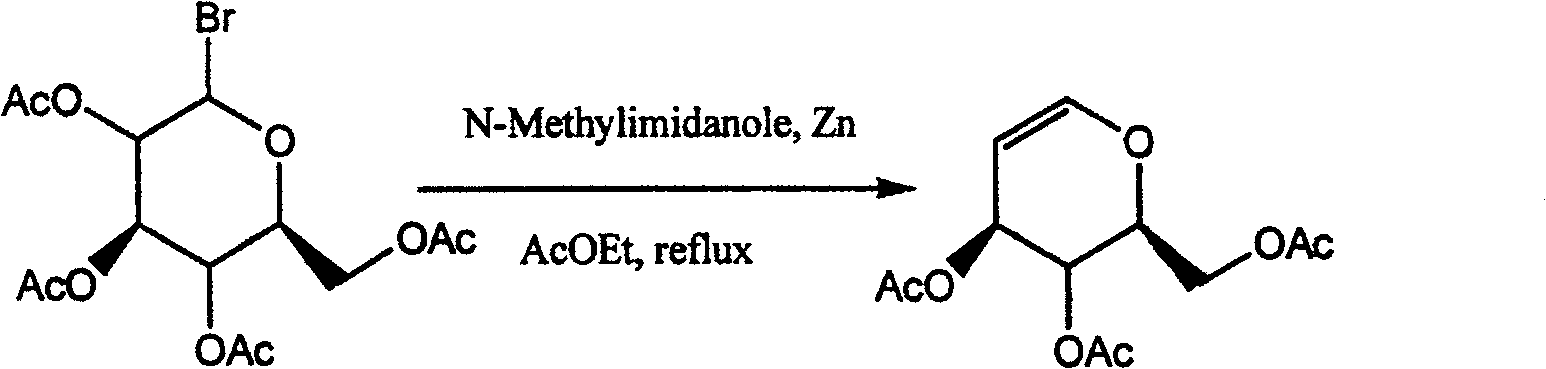

Method used

Image

Examples

example 1

[0026] Example 1: Add 40mL phosphate buffer solution (the weight ratio of disodium hydrogen phosphate, sodium dihydrogen phosphate to water is 11:14:100) in a 100mL round bottom flask, add 2.1g zinc powder, 0.21g copper sulfate , stirred, then added 2.1g 1-bromoacetylglucose, stirred at room temperature for 8 hours, after TLC detected that the reaction was complete, added 2.1g NaOH to the above reaction solution, and stirred at room temperature for 3 hours. After purification by silica gel column, 0.717 g of pure glucal sugar was obtained with a yield of 96%.

example 2

[0027] Example 2: Add 20mL phosphate buffer solution (the weight ratio of disodium hydrogen phosphate, sodium dihydrogen phosphate to water is 11:14:100) in a 100mL round bottom flask, add 1.0g zinc powder, 0.1g copper sulfate , stirred, then added 1.0 g of 1-bromoacetylglucose, and stirred at room temperature for 5 hours. After the reaction was complete as detected by TLC, 1.0 g of KOH was added to the above reaction solution, and stirred at room temperature for 1.5 hours. Purified by a silica gel column to obtain 0.334 g of pure glucuronose with a yield of 94%.

example 3

[0028] Example 3: Add 2.0g of sodium dihydrogen phosphate, 10mL of water, and 1.0g of zinc powder into a 50mL round bottom flask, stir, then add 1.0g of 1-bromoacetylglucose, stir at room temperature for 0.5 hours, and detect the reaction by TLC After completion, 1.0 g of KOH was added to the above reaction solution, and the reaction was stirred at room temperature for 0.5 hours. Purified by a silica gel column to obtain 0.312 g of pure glucal sugar with a yield of 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com