Pre-baked anode for aluminum electrolysis and its preparation method

A pre-baked anode and aluminum electrolysis technology, applied in the field of aluminum electrolysis, can solve the problems of large power consumption gap and low comprehensive energy utilization efficiency, and achieve the effects of improving efficiency, high comprehensive energy utilization rate and good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

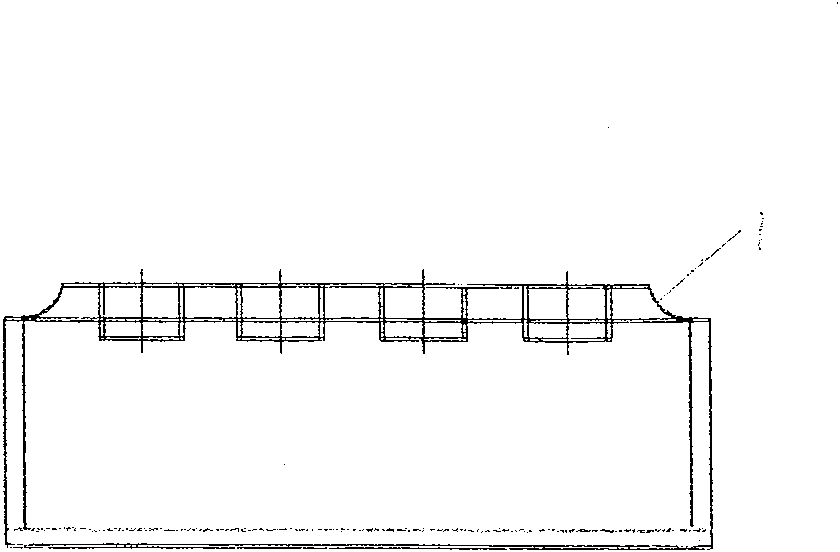

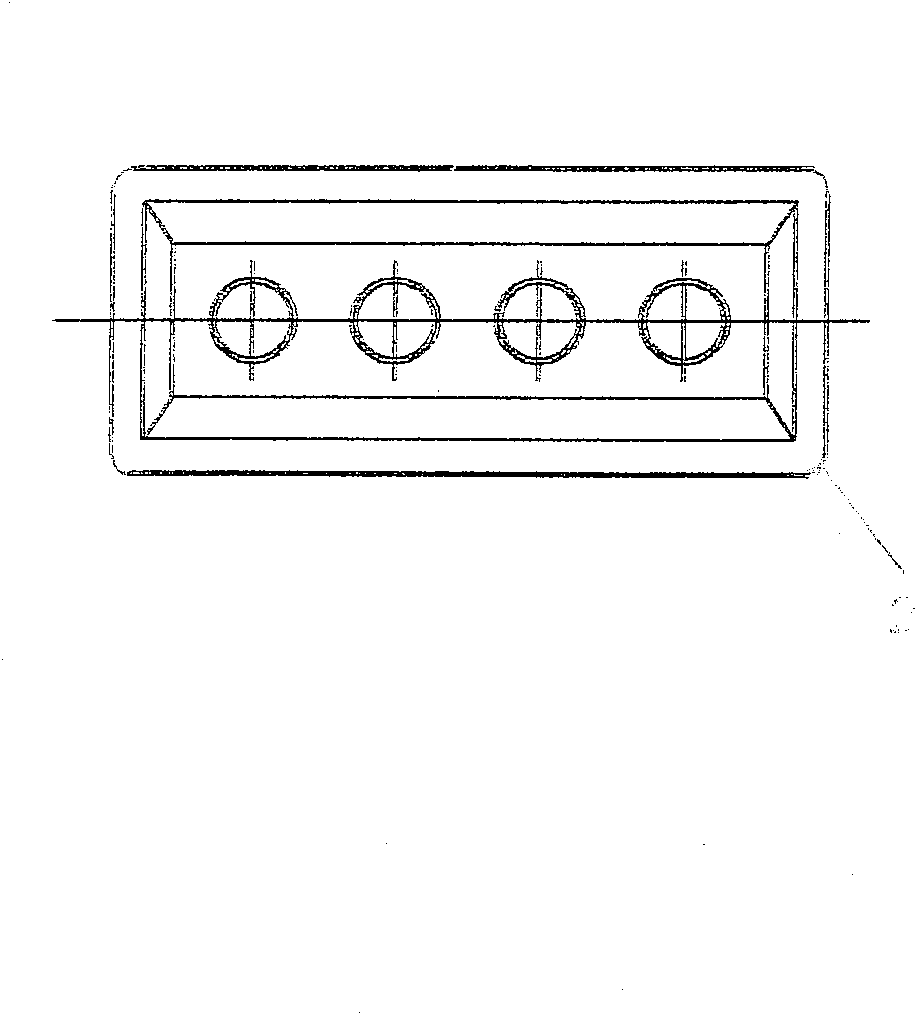

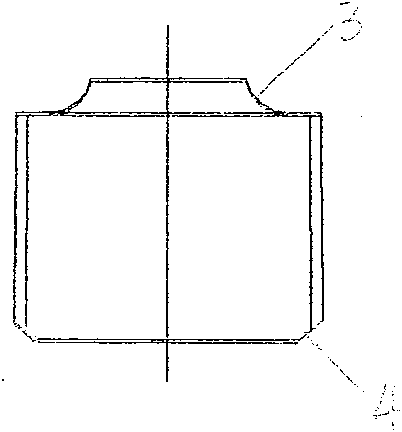

[0021] 1) Optimal design of the prebaked anode shape: the inclined surface of the truss part on the upper part of the carbon anode is a concave surface, such as figure 1 1 in and image 3 As shown in 3; the four corners of the carbon anode are arc-shaped corners, such as figure 2 2 in ; the two long sides at the bottom of the carbon anode are square chamfers, such as image 3 Shown in 4.

[0022] 2) In the production process of the carbon anode (block), the scrap aluminum wire produced in the aluminum processing production process is mixed as an additive to improve the electrical conductivity of the carbon anode, that is, 1.5‰ of the aluminum wire is added in the production process of the carbon anode. During the process, when these aluminum wires change from solid phase to liquid phase, they are filled and compounded into the micropores of carbonaceous particles, so that the carriers of the carbon anode matrix increase, thus increasing the concentration of the carbon anode...

Embodiment 2

[0024] 1) The optimal design of the prebaked anode shape is the same as in Example 1;

[0025] 2) In the production process of carbon anode (block), the scrap aluminum wire produced in the aluminum processing production process is mixed as an additive to improve the electrical conductivity of the carbon anode, that is, 2.0‰ of aluminum wire is added in the production process of the carbon block. During the process, when these aluminum wires change from solid phase to liquid phase, they are filled and compounded into the micropores of carbonaceous particles, so that the carriers of the carbon anode matrix increase, thus increasing the concentration of the carbon anode carriers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com