Underwater grouting shaping type submarine pipeline vertical tube fixing device

A subsea pipeline and underwater grouting technology, which is applied in the direction of pipeline support, pipeline laying and maintenance, pipe/pipe joint/pipe fitting, etc. It can solve problems such as economic loss, loosening of pipe clamp bolts, loss of pipe fixing effect, etc., and achieve cost saving , The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

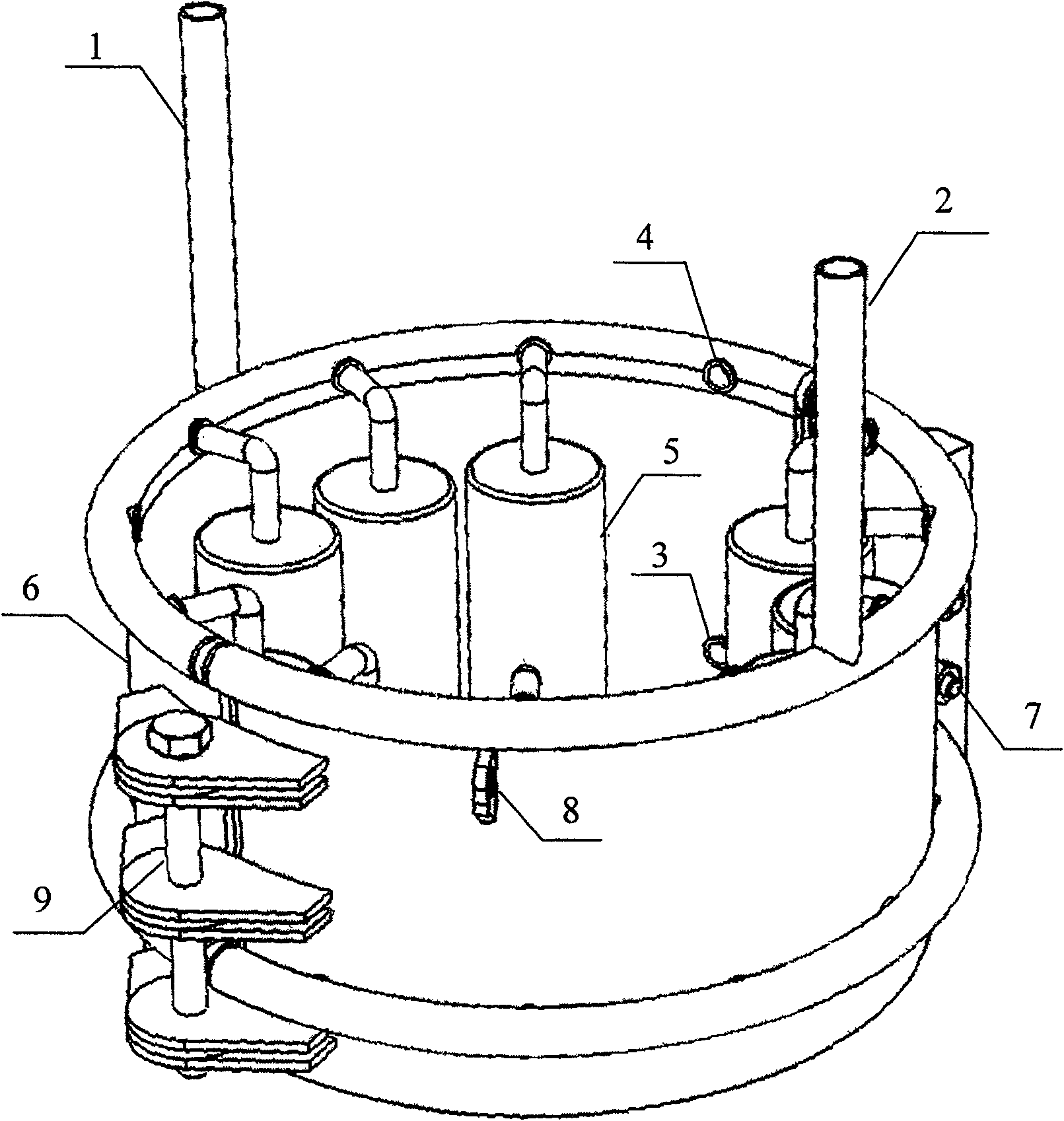

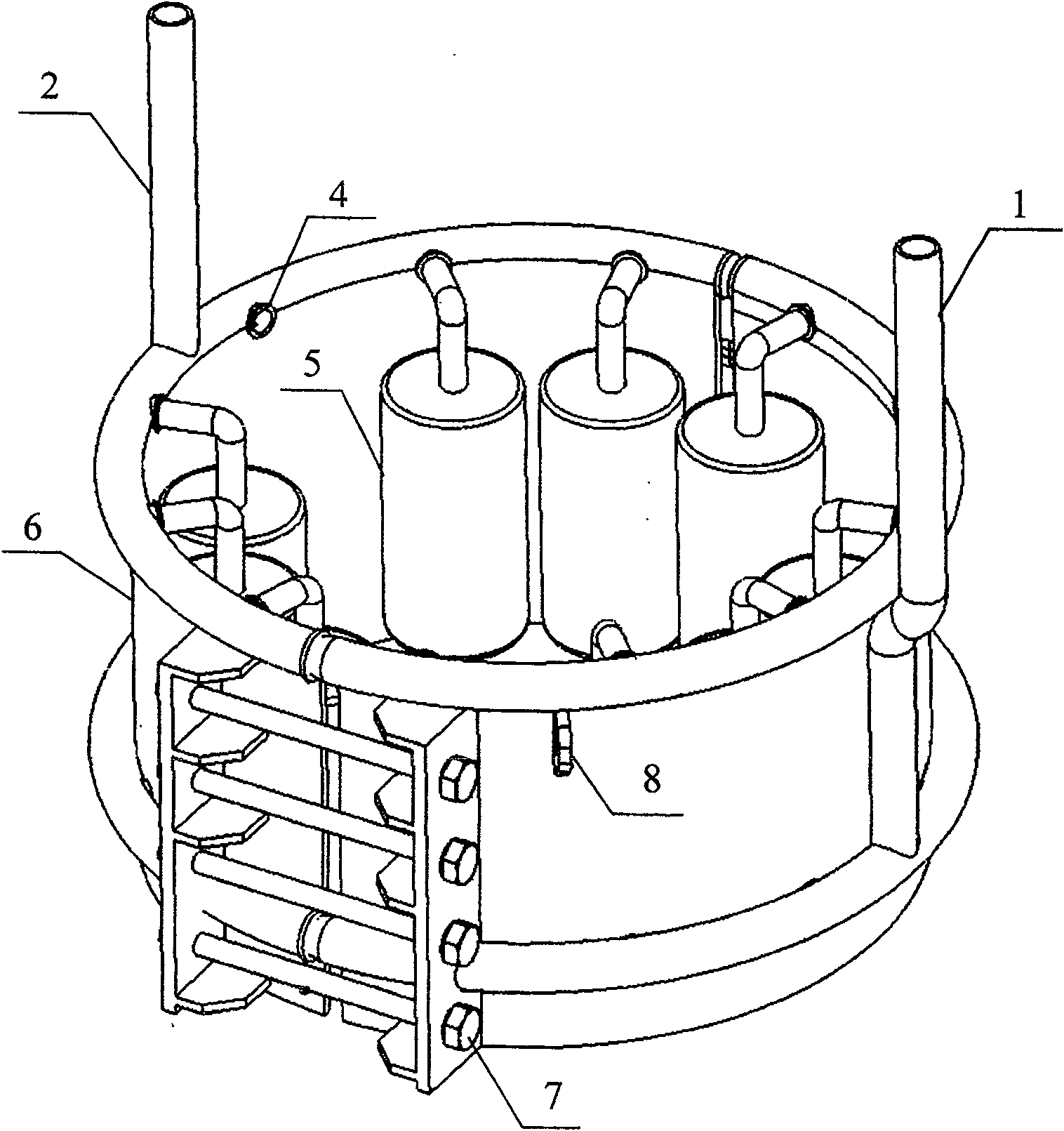

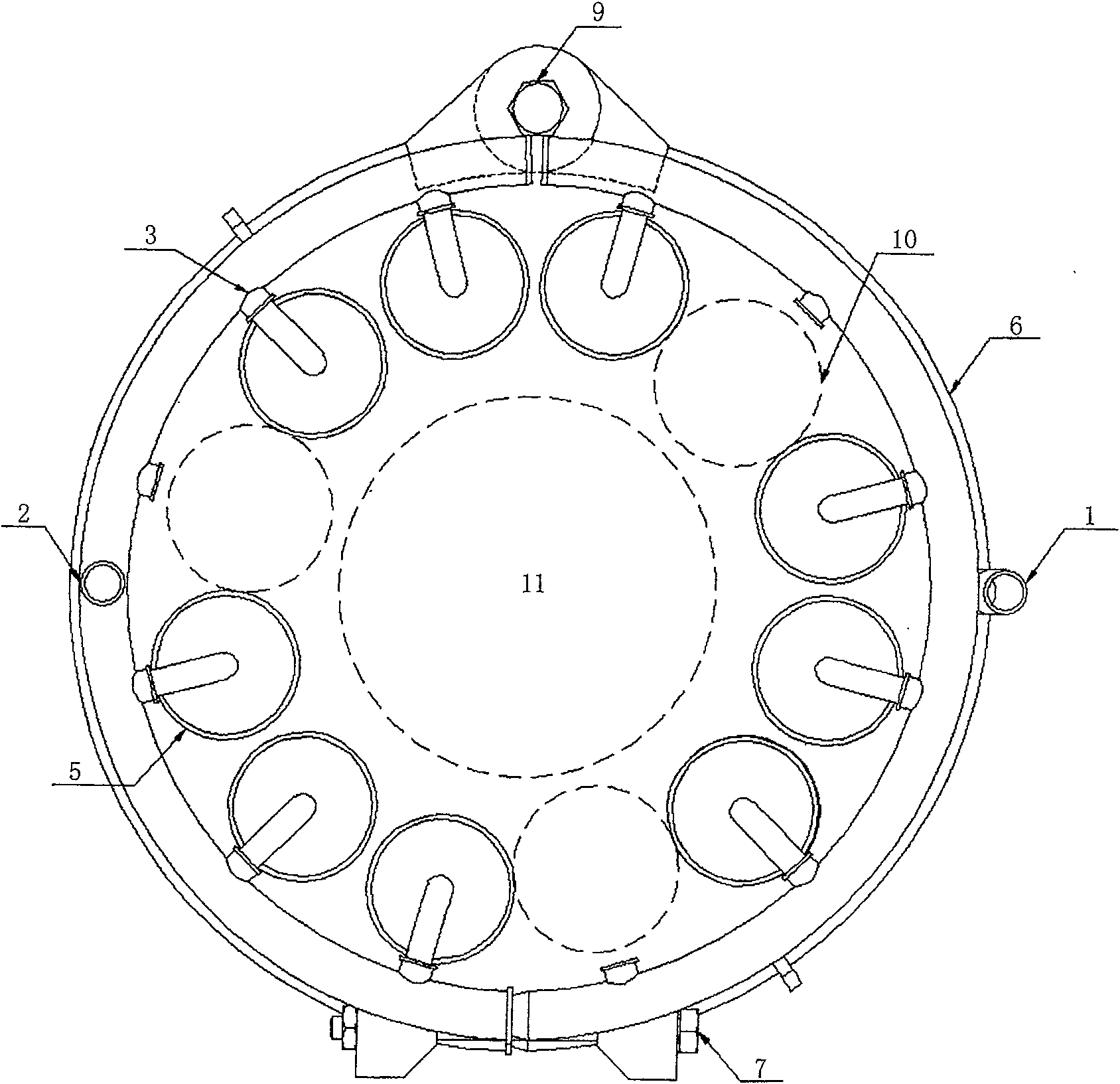

[0011] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0012] The present invention is composed of a clasp 6 and an elastic capsule 5, and is characterized in that the clasp is set in a cylindrical shape and is composed of two symmetrical circular arc bodies, and a pin shaft connection mechanism is correspondingly provided on both sides of the symmetrical line of the two petal arc bodies 9 and the bolt connection mechanism 7, symmetrical round tubes are arranged on the upper and lower ends of the two-lobed arc bodies, and plug-in sealing joints are provided between the round tube counterparts, and the symmetrical round tubes are welded together with the two-lobed arc bodies respectively; Several cylindrical elastic capsules are arranged vertically within the 3 angles of 120° on the inner side of the 360° circle formed by the two-petal arc bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com