Process of producing alkyd resin using waste oil

A technology of alkyd resin and waste oil, applied in the field of fine chemicals, can solve the problems of high product cost, poor gloss, poor hardness and dryness, etc., and achieve stable and reliable product quality, eliminate table pollution, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

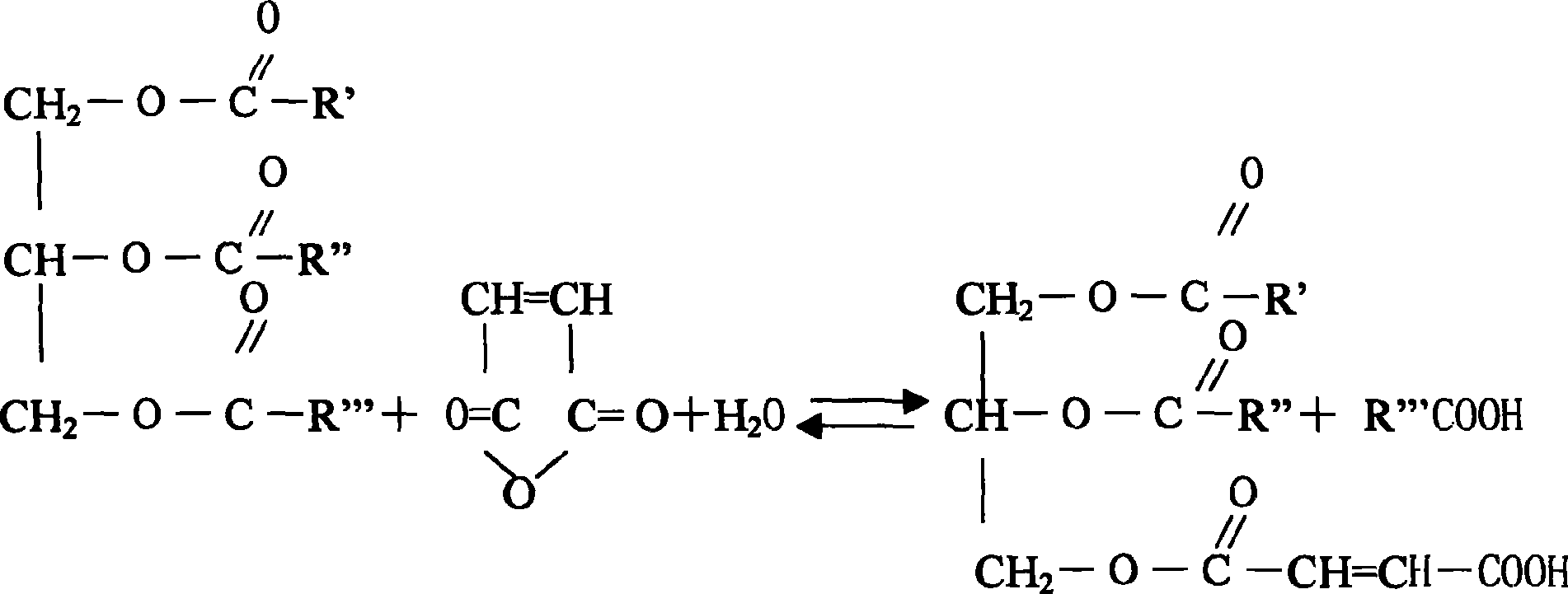

Method used

Image

Examples

Embodiment

[0017] a. Using gutter oil to produce alkyd resin raw material formula: use pentaerythritol as polyhydric alcohol, phthalic anhydride as polybasic acid, xylene as reflux solvent, tall oleic acid as monobasic acid, 200 # The solvent is used as a diluting solvent, and the formulations of raw and auxiliary materials are as follows.

[0018] raw material

Feeding amount, Kg

Specification

1000-1200

/

tall oil acid

200-300

Industrial products

Auxiliary

1-5

Chemicals

30-70

Industrial products

300-500

Industrial products

300-460

Industrial products

150-200

Industrial products

200 # solvent

1500-2000

Industrial products

[0019] b. Production process

[0020] Put waste oil and tall oil acid into the pot, add additives when the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com