Magnetic conversion motor

A technology of engines and motors, applied in the direction of magnetic circuit rotating parts, electric components, electromechanical devices, etc., can solve problems such as failure to meet design requirements, and achieve the effects of good dynamic response, adjustable speed, and large speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

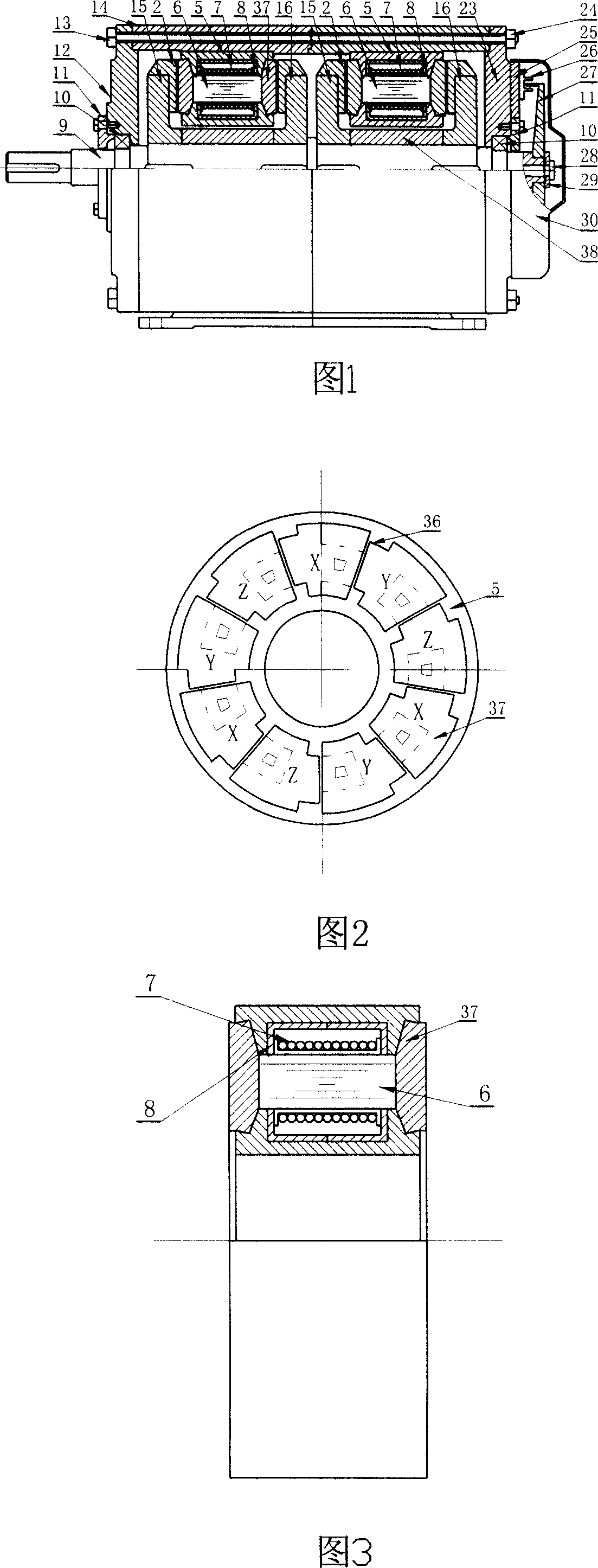

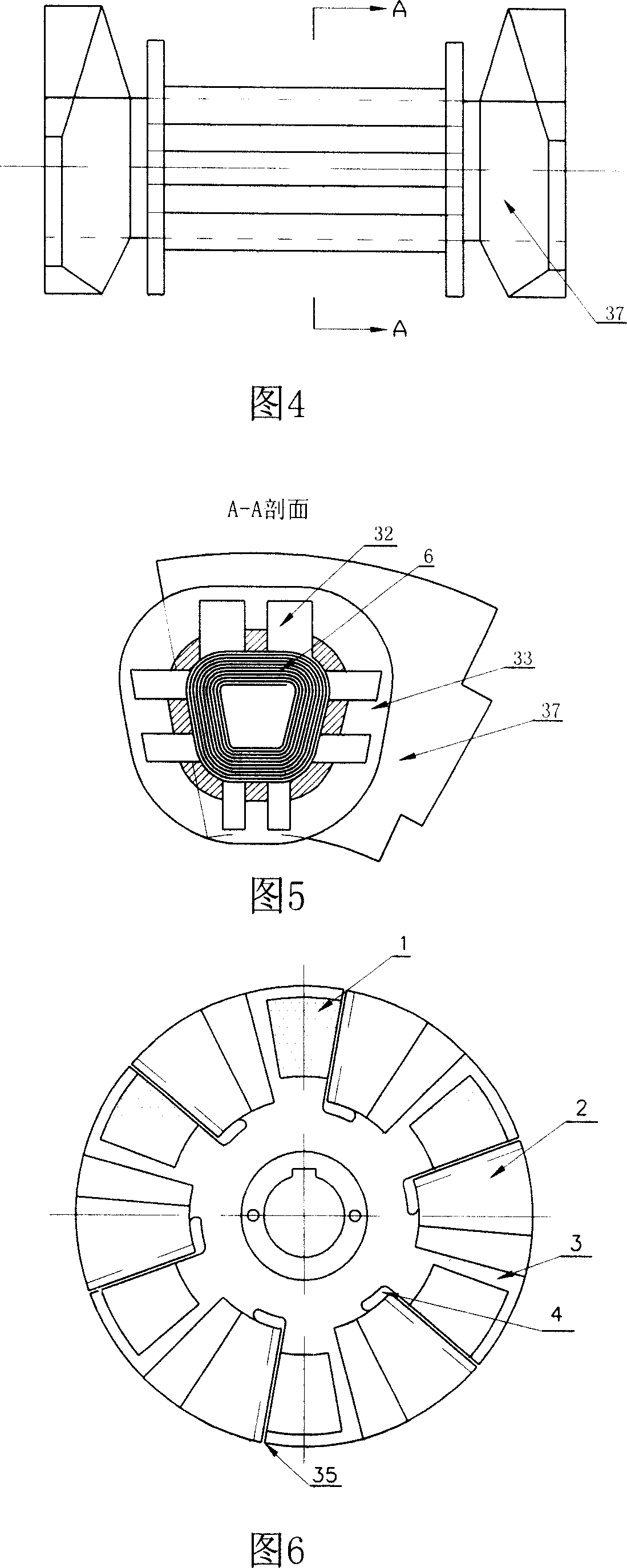

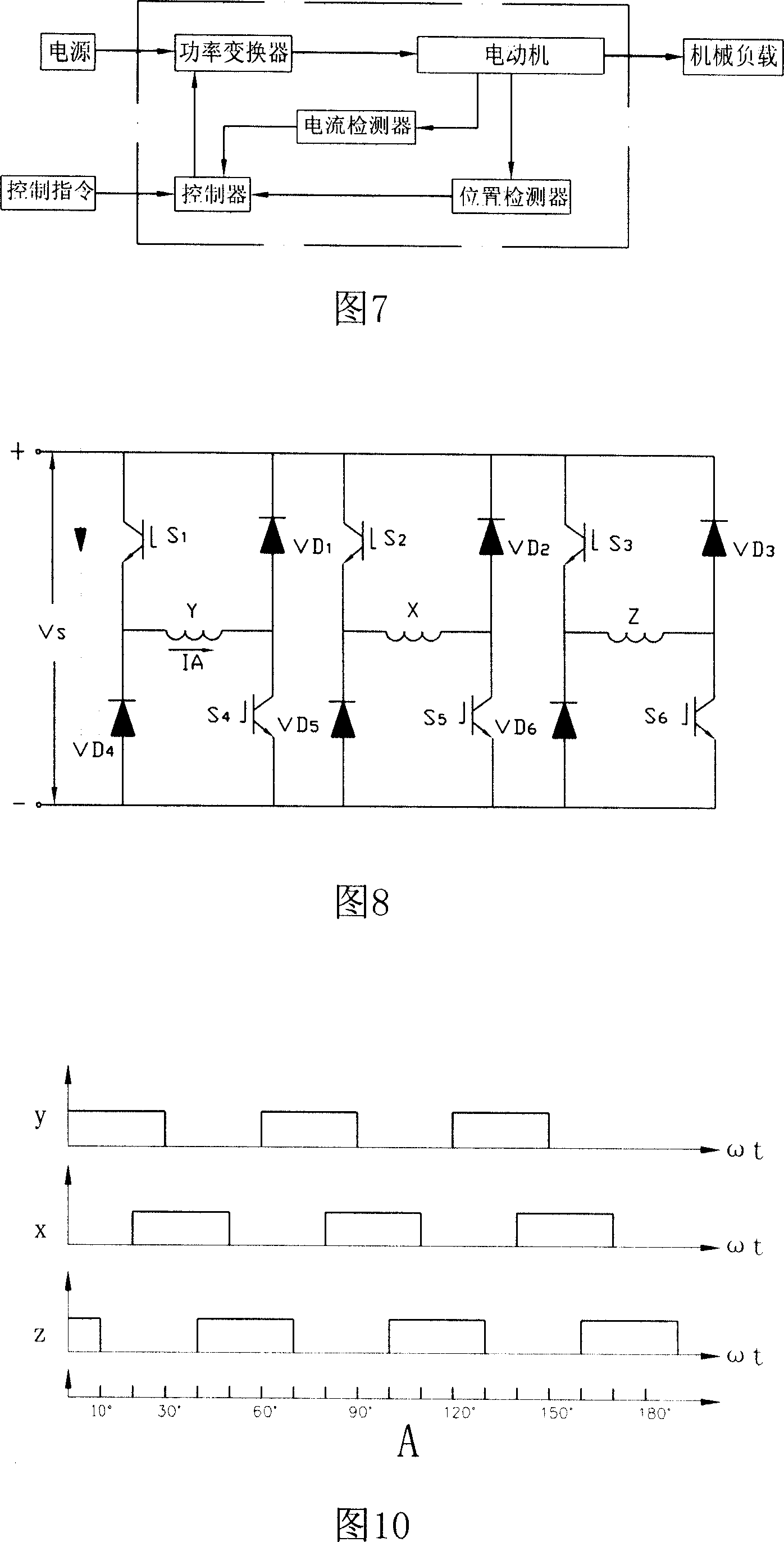

[0042] The overall structure of the magnetic conversion motor according to the present invention is shown in Figure 1, wherein 1 is a permanent magnet, 2 is a rotor soft magnetic pole, 3 is a rotor, 4 is a rotor gap, 5 is a stator, 6 is a winding core, 7 is Winding coil, 8 is an inner mold, 9 is a shaft, 10 a bearing, 11 is a bearing end cover, 12 is a left end cover, 13 is a bolt, 14 is a machine base, 15 is a left rotor, 16 is a right rotor, and 17 is a dividing plate, 18 is the generator stator winding, 19 is the generator stator, 20 is the generator rotor, 21 is the generator rotor winding, 22 is the slip ring, 23 is the right end cover, 24 is the nut, 25 is the photoelectric device fixing plate, 26 is the photoelectric Devices, 27 is the light chopper, 28 is the fastening bolt of the light chopper, 29 is the washer, 30 is the shield, 31 is the ventilation hole, 32 is the oil circuit, 33 is the winding frame, 34 is the commutator, 35 is the soft The gap between the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com