Shaped vulcanizing method of vibrating rubber tire and exciting device

The technology of an excitation device and rubber tires is applied in the direction of vibrating fluids, tires, household appliances, etc., which can solve the problems of not seeing the vulcanization and setting process of rubber tires, so as to promote full stretching, save lanugo hair removal process, and simplify The effect of mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

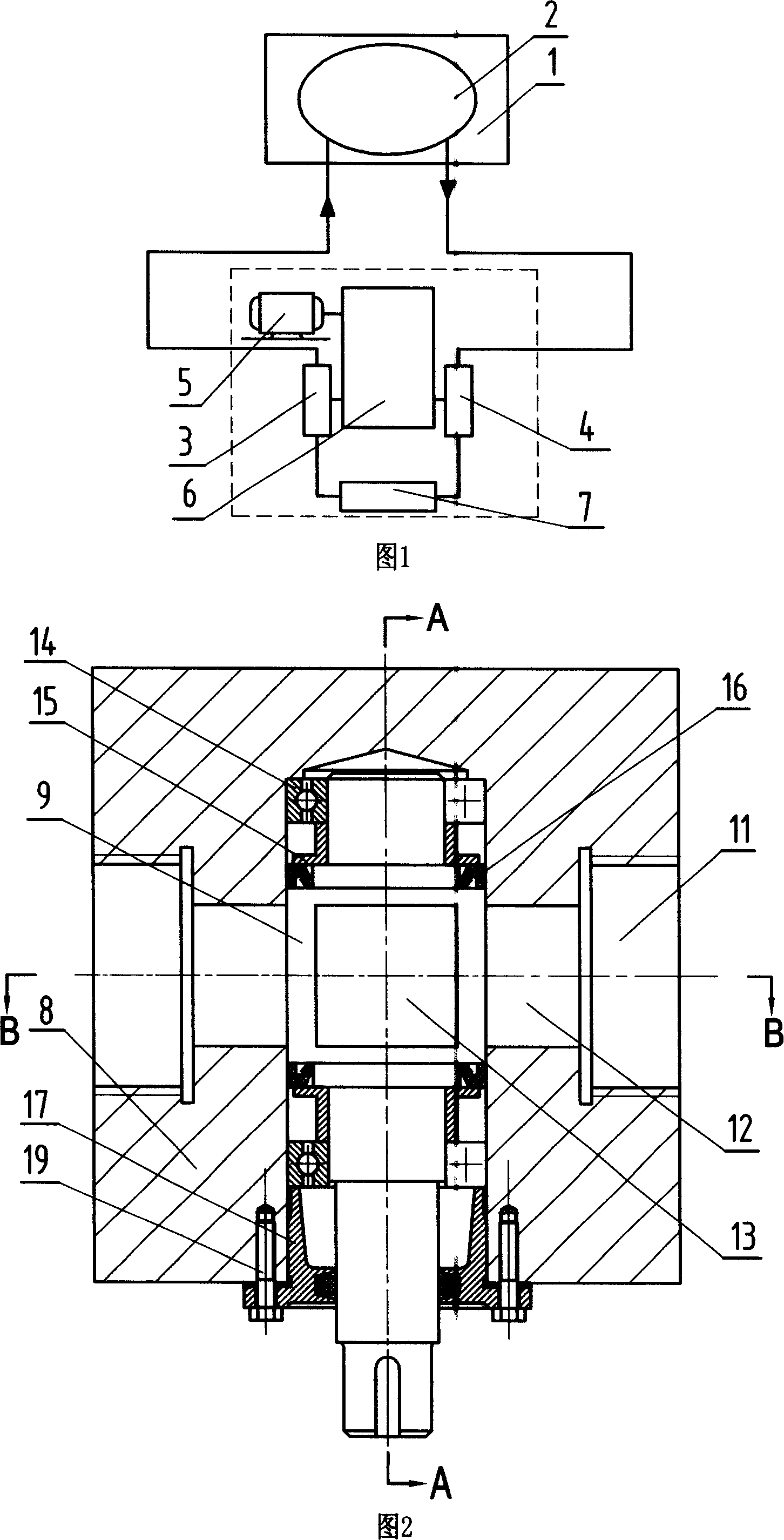

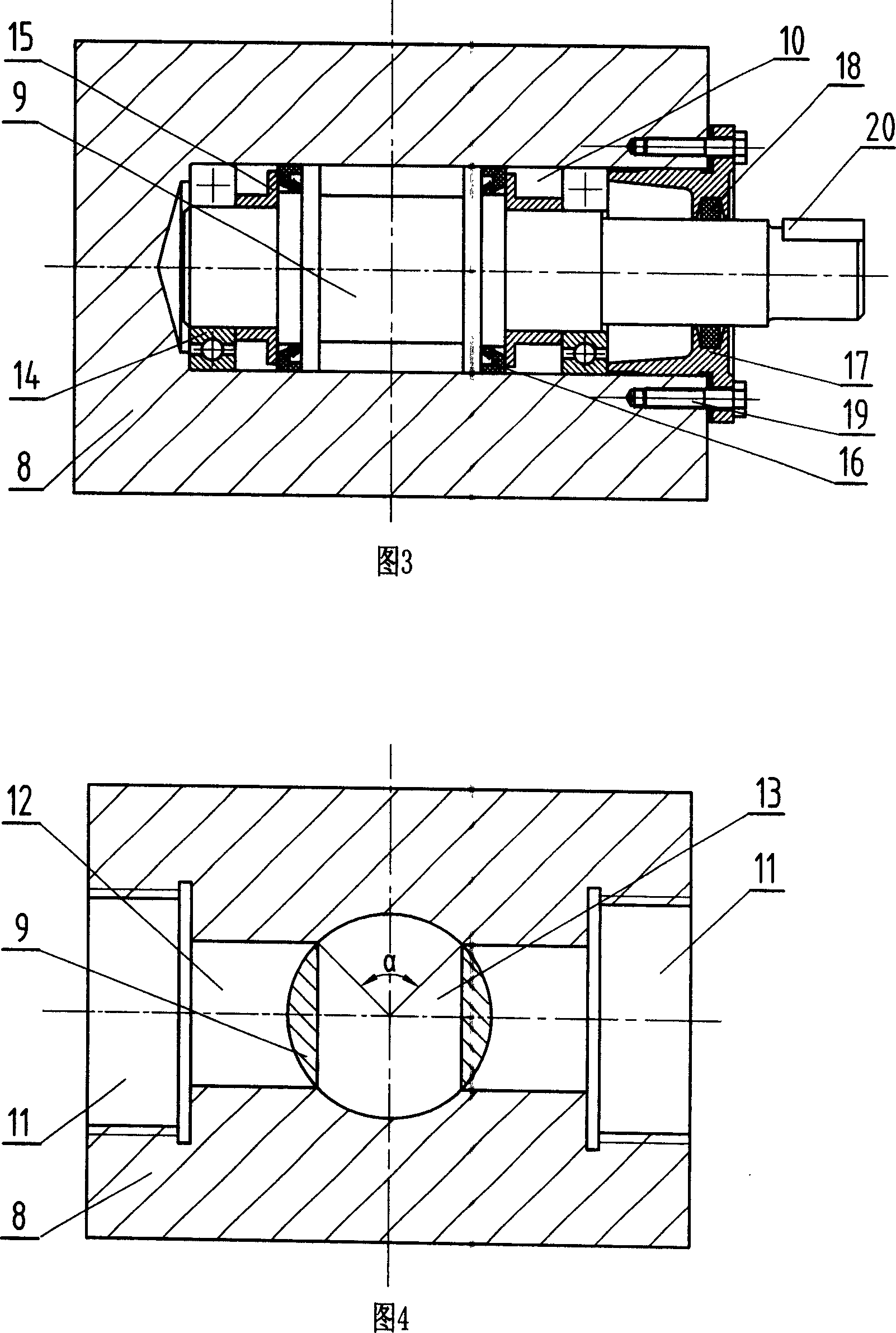

[0024] Install the vibration excitation device on the thermal pipeline system of the vulcanizer, as shown in Figure 1, the thermal pipeline system communicates with the capsule 2 in the mold 1 of the vulcanizer, and the vibration excitation device passes through the thermal pipeline system in the vulcanizer. The fluid medium vibrates the tire in the vulcanizer, and the vibration excitation is applied to the vulcanization process of the rubber tire.

[0025] The vibration excitation device of the present invention is a kind of mechanical vibration excitation device, as shown in Figure 1, it is made up of inlet vibration valve 3, outlet vibration valve 4, motor 5, speed changer 6 and stepless speed regulation pump 7, inlet The excitation valve 3 and the outlet excitation valve 4 are connected with the motor 5 through the transmission 6 . The transmission 6 can be a gear-driven ZDY transmission, its assembly type is VI, one of its input ends is connected with the motor 5, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com