A kind of silicone adhesion promoter and preparation method and application thereof

An adhesion promoter and silicone technology, applied in the direction of adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of inability to meet the needs of use, decrease in bonding strength, flow, etc., and improve the adhesion. Effects of performance and mechanical properties, mechanical strength enhancement, cohesion enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

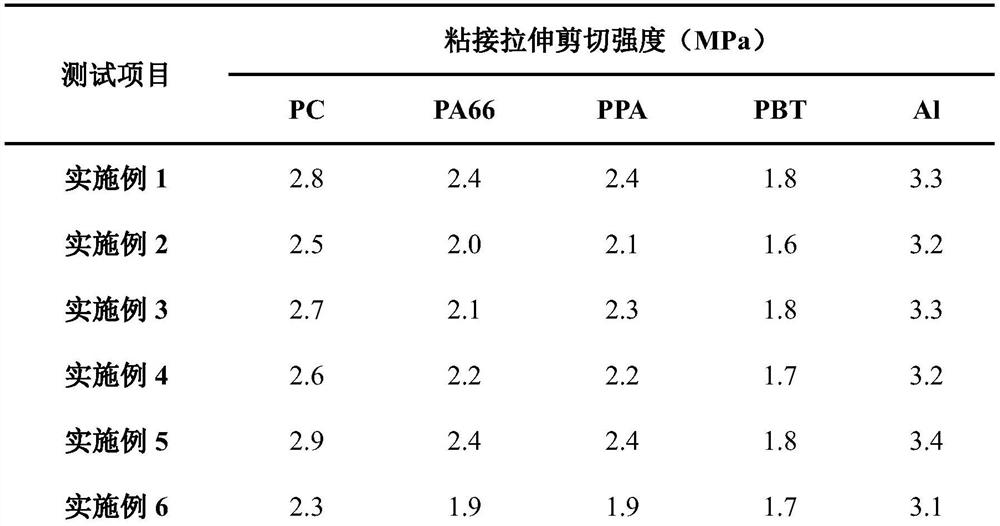

Embodiment 1

[0053] A kind of organosilicon adhesion promoter, its preparation method comprises the following steps:

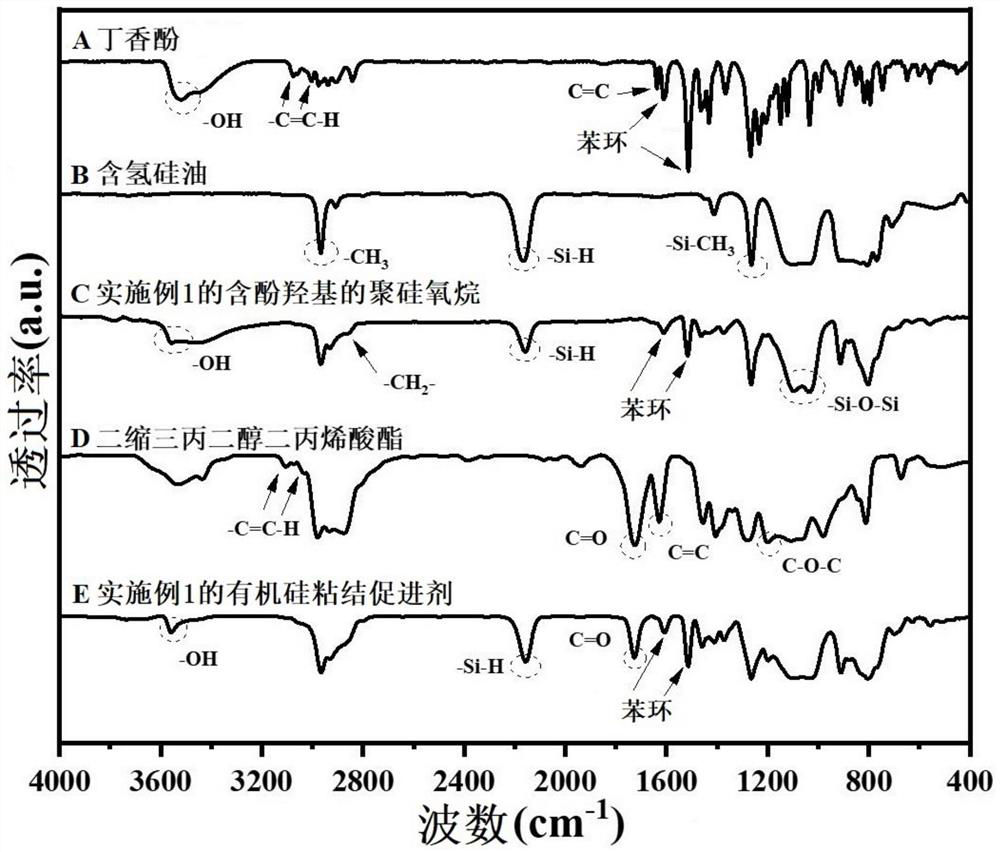

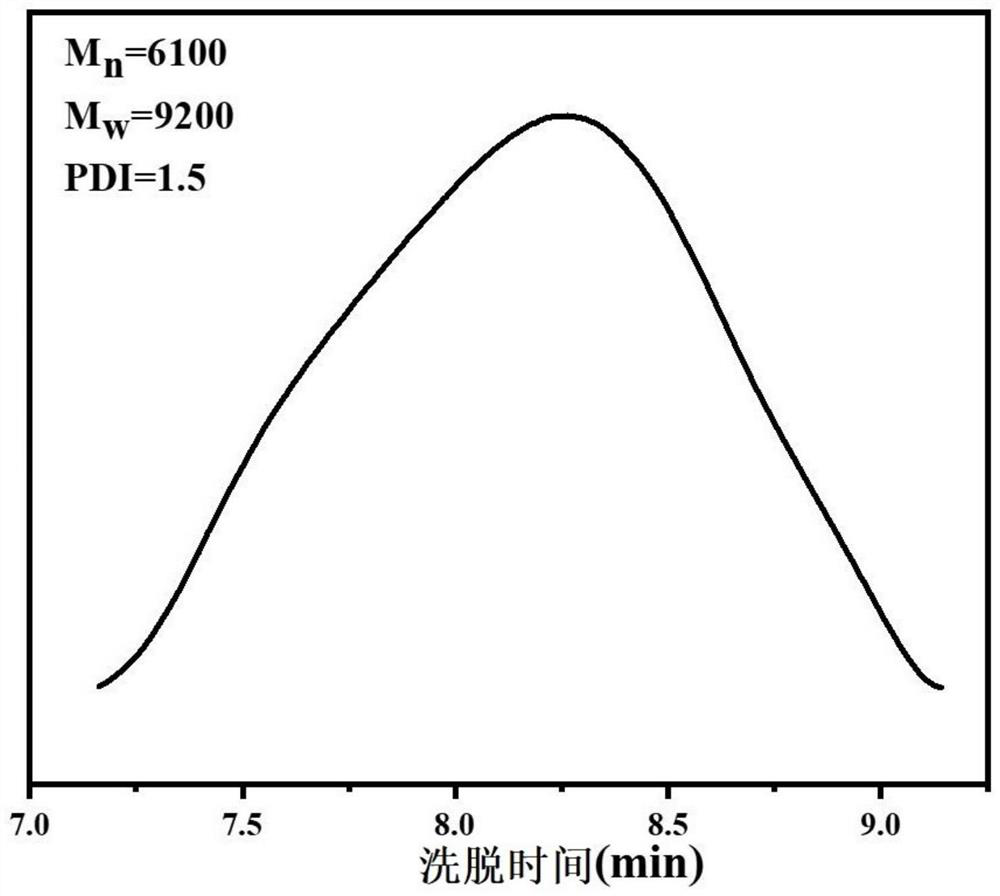

[0054] 1) Add 10g of isopropanol, 1.64g of eugenol (containing 0.01mol of C=C) and 3.78g of hydrogen-containing silicone oil (containing 0.03mol of Si-H) at 25°C 100mL reaction kettle, stirred for 30min, then slowly added 0.01g of Karstedt platinum catalyst with a platinum concentration of 2000ppm into the reaction kettle, raised the temperature to 80°C after the addition, and reacted for 3h to obtain polysiloxane containing phenolic hydroxyl groups;

[0055] 2) 10 g of isopropanol, 0.02 g of Karstedt platinum catalyst with a platinum concentration of 2000 ppm, and 3.01 g of tripropylene glycol diacrylate (containing 0.02 mol of C=C) were mixed and stirred for 20 minutes at 20° C. to prepare a mixed solution, Slowly add it dropwise to the phenolic hydroxyl-containing polysiloxane in step 1) at 60°C, finish adding in 1 hour, then continue to react for 3 hours, then add activa...

Embodiment 2

[0070] A kind of organosilicon adhesion promoter, its preparation method comprises the following steps:

[0071] 1) At 40° C., 10 g of tetrahydrofuran, 1.34 g of 2-allylphenol (containing 0.01 mol of C=C) and 1.34 g of hydrogen-containing MQ silicone resin with a hydrogen content of 1.5 wt % (containing 0.02 mol of Si -H) Add a 100mL reaction kettle, stir for 40min, then slowly add 0.06g of tetrahydrofuran solution of chloroplatinic acid with a platinum concentration of 4000ppm into the reaction kettle, heat up to 60°C after the addition, and react for 3h to obtain polysilicon containing phenolic hydroxyl groups Oxygen;

[0072] 2) Mix 10 g of tetrahydrofuran, 0.09 g of tetrahydrofuran solution of chloroplatinic acid with a platinum concentration of 4000 ppm, and 12.10 g of tripropylene glycol diacrylate (containing 0.04 mol of C=C) at 25°C for 30 minutes to prepare a mixed solution , and then slowly added dropwise to the polysiloxane containing phenolic hydroxyl groups in st...

Embodiment 3

[0076] A kind of organosilicon adhesion promoter, its preparation method comprises the following steps:

[0077] 1) Mix 10g of ethanol and 1.33g of 3',5-di-2-propenyl-1,1'-biphenyl-2,4'-diphenol (containing 0.01mol of C=C) at 10°C Add 3.03g of hydrogen-containing silicone oil (containing 0.03mol of Si-H) with a hydrogen content of 1.0wt% into a 100mL reactor, stir for 30min, then slowly add 0.05g of Karstedt platinum catalyst with a platinum concentration of 3000ppm into the reactor, and finish adding Afterwards, the temperature was raised to 50°C and reacted for 2 hours to obtain polysiloxane containing phenolic hydroxyl groups;

[0078] 2) Mix 10 g of ethanol, 0.04 g of Karstedt platinum catalyst with a platinum concentration of 3000 ppm, and 2.26 g of 1,6-hexanediol diacrylate (containing 0.02 mol of C=C) at 40°C for 40 minutes to form a mixture Solution, then slowly added dropwise to the polysiloxane containing phenolic hydroxyl group in step 1) at 75°C, the addition was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com