Modular air-floating type artificial mattress for processing polluted water, its manufacture method and purification method

A sewage biological treatment, modular technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Formation and other problems to achieve the effect of inhibiting algae growth, improving self-purification ability, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

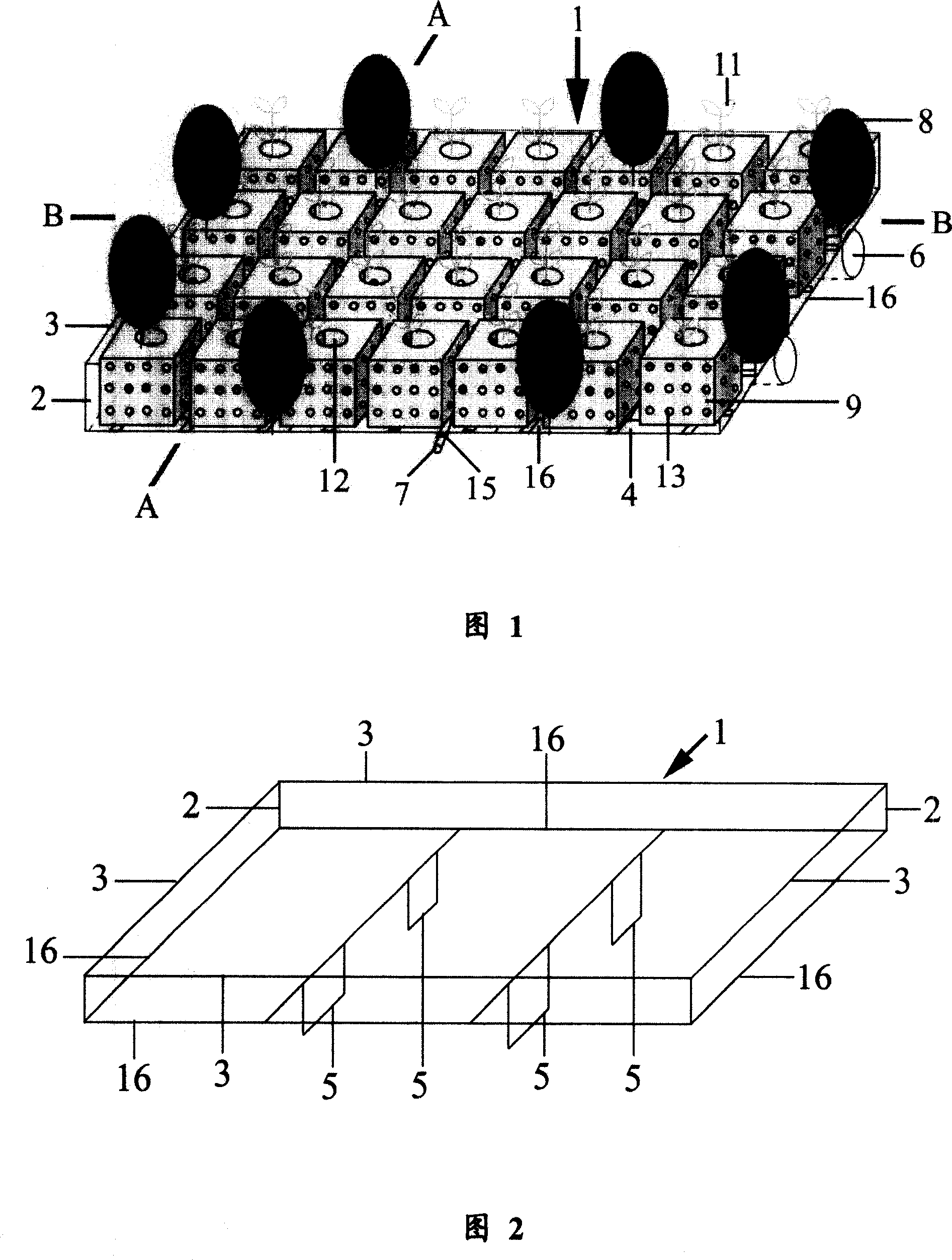

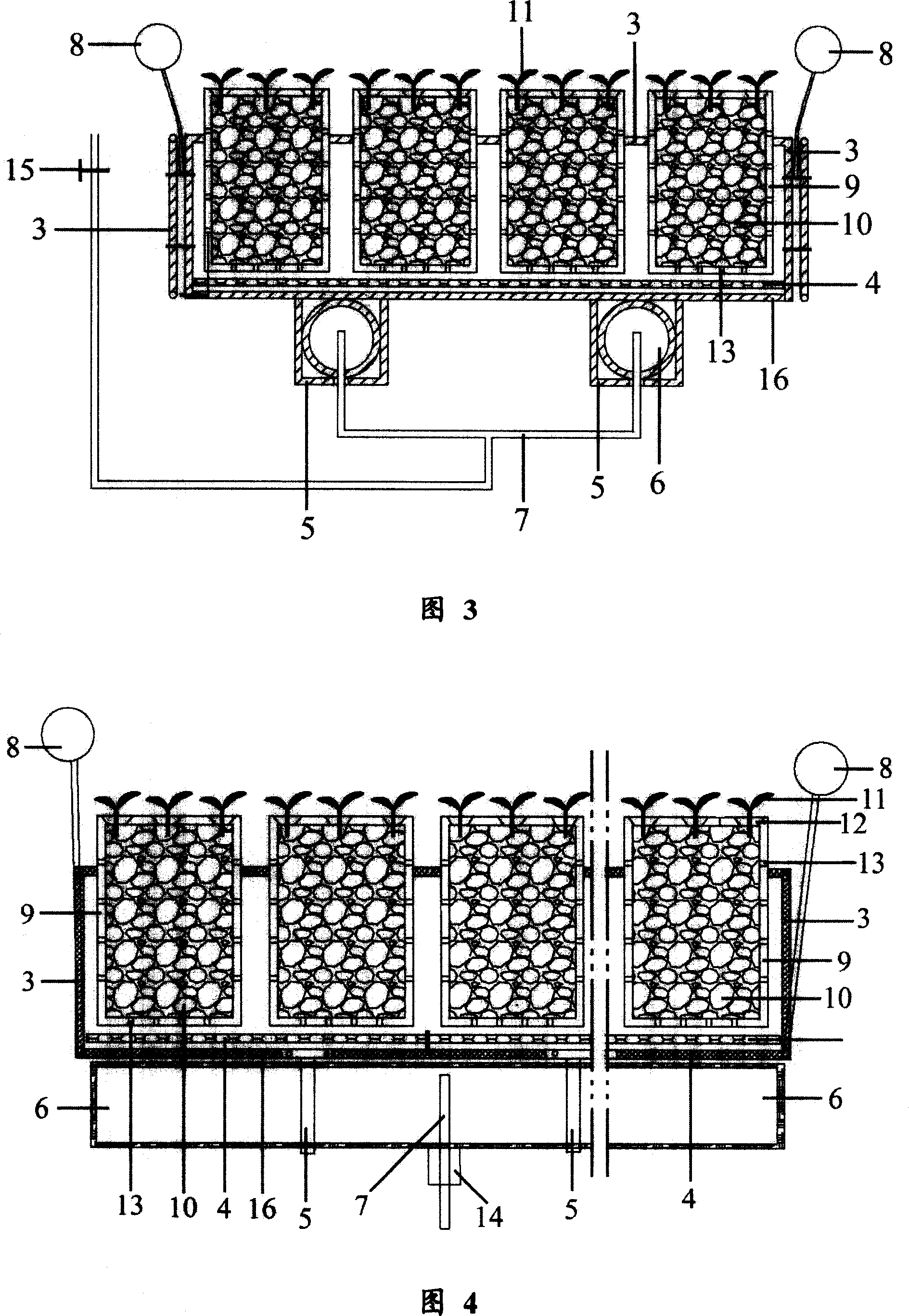

[0035] The main frame bed body (1) is a rod system frame structure, and the whole is a cubic box. The bed bottom (16) of the main frame bed body (1) is connected equidistantly by several columnar pipes, and the main frame bed body (1 ) At least three bed corners (2) are equidistantly arranged around the bottom of the bed (16). 1) is an annular bed side (3) extending upward from the periphery of the bottom of the bed, and the bed side (3) of the main frame bed body (1) is composed of several columnar pipes connected with the bed corners (2), and the main frame bed body ( 1) The top is open, and several U-shaped buoy holders (5) are arranged opposite to the bottom of the bed of the main frame bed (1), and the U-shaped ends of the buoy holder (5) and the main frame bed (1) The bottom of the bed (16) pipes are connected.

[0036] At least one grid plate (4) is placed on the bed bottom (16) of the main frame bed body (1), and the grid plate (4) covers the entire bed bottom (16), a...

Embodiment 2

[0042] The cross-section of the main frame bed body (1) is rectangular, square, circular or polygonal, and at least one type is used. The cross-sectional area of planting box (9) is rectangle or square or circle or polygon, adopts more than one kind at least, as shown in Fig. 1, Fig. 3, Fig. 4.

Embodiment 3

[0044] The filling matrix (2) in the planting box (9) is crushed stone, ceramsite, volcanic basalt, polystyrene balls, and the particle size is 10-15mm. At least one of them is used, as shown in Fig. 1, Fig. 2, Fig. 3, Figure 4 shows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com