Method for correcting gross error and random error of measurement data

A random error and measurement data technology, which is applied in the direction of electrical digital data processing, special data processing applications, and mitigation of unwanted effects, to achieve the effects of reducing negative effects, reducing missed judgments and misjudgments, and improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

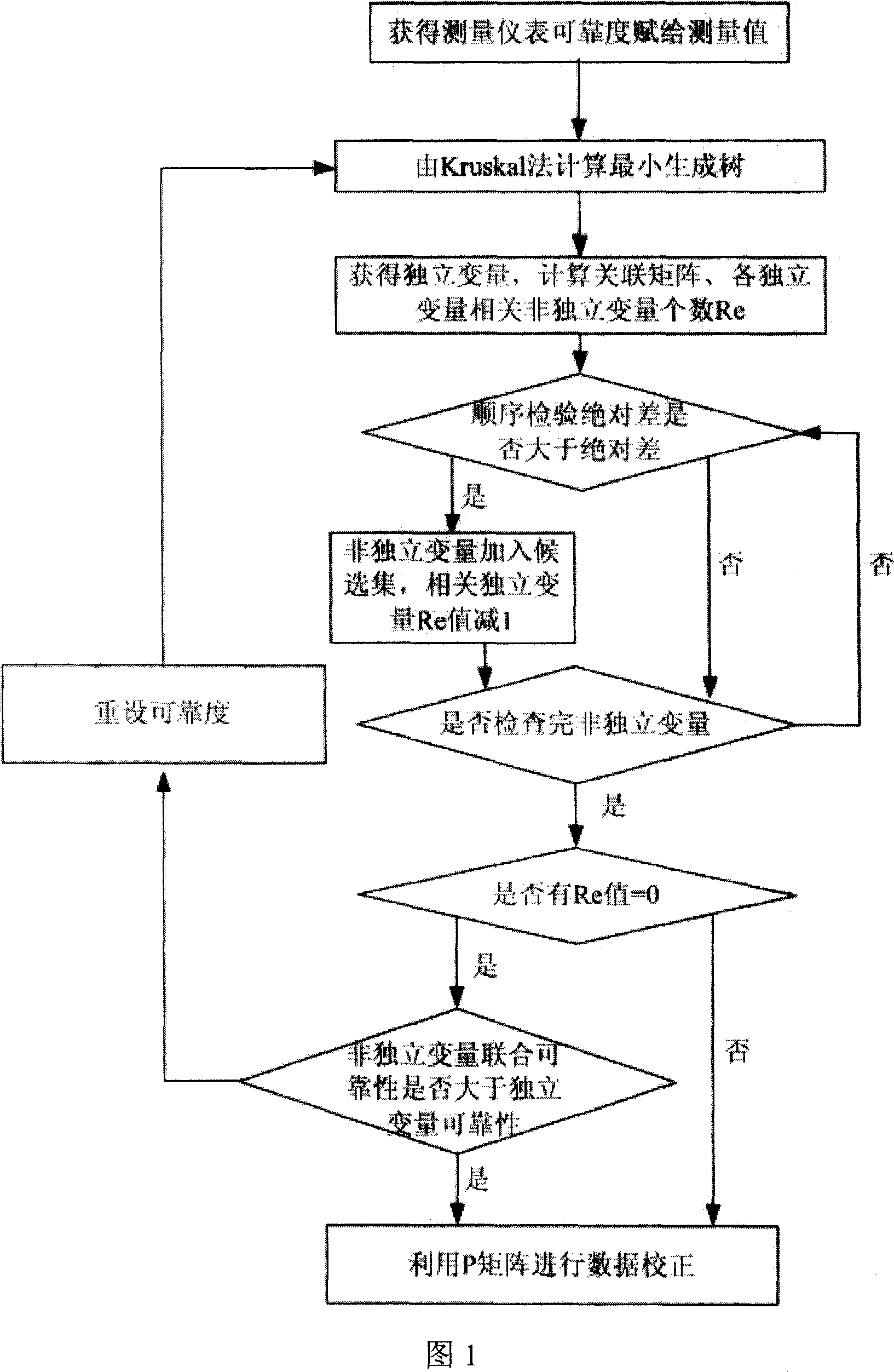

Method used

Image

Examples

Embodiment 1

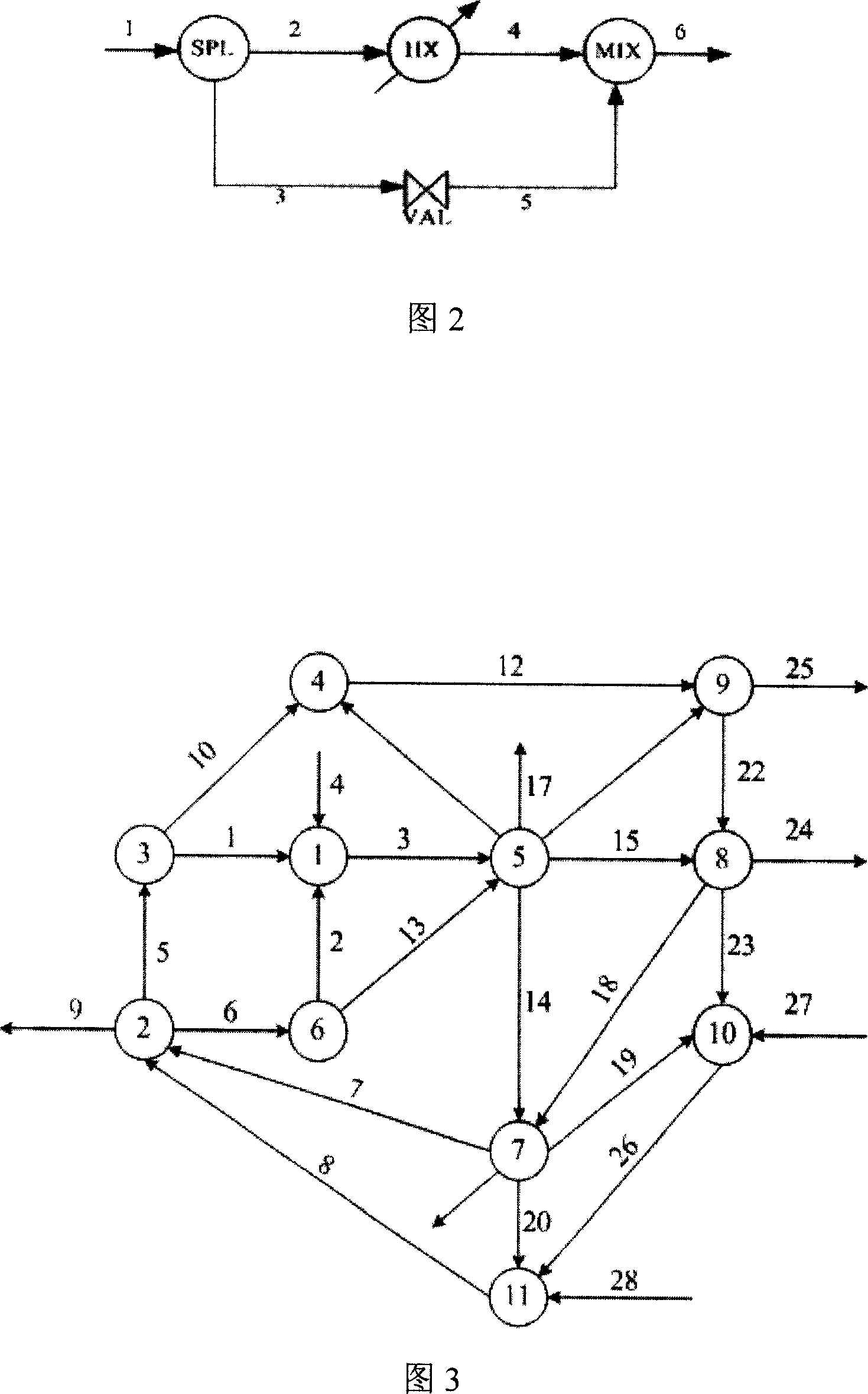

[0054] Taking a certain heat exchange network shown in Figure 2 as an example, there are four devices including a splitter SPL, a heat exchanger HX, a mixer MIX and a valve VAL, and 6 measurement points located at the input and output ends of the device. Table 1 lists the true value, measured value, standard deviation and reliability of the network measurement points.

[0055] Table 1

[0056] Measurement point number

[0057] Note: *--measurement data contains significant error

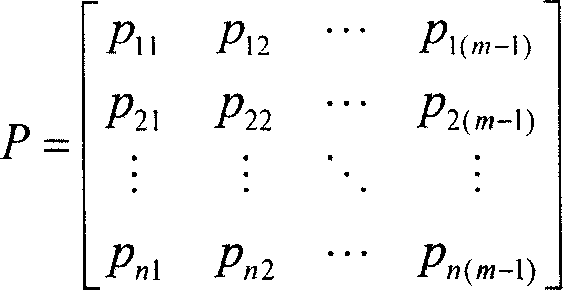

[0058] In the 1# measurement value, because the measurement point F 3 and F 4 The reliability of is higher than other measurement points, they are selected as independent variables, then calculate the P matrix as:

[0059] 1 1 0 1 0 1 ...

Embodiment 2

[0069] The steam system containing 11 nodes and 28 streams shown in accompanying drawing 3 is taken as an example to test the present invention, and the standard widely adopted in the world is introduced:

[0070]

[0071]

[0072] The effectiveness of significant error detection is evaluated. Table 3 shows the effect of the application and the comparison with the commonly used MIMT significant error detection method.

[0073] Table 3. Significant error detection effect

[0074] Number of simulations

[0075] It can be seen from Table 3 that the significant error detection rate of this method is higher than that of MIMT method, and the method of sharing correlation matrix makes data correction benefit at the same time, and improves the efficiency of data correction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com