Silicon oil coating device of conveyor belt plate vulcanizer

A technology of flat vulcanization and conveying belt, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of uneven spraying of silicone oil on the surface of the tape, affecting product quality, and difficulty in cleaning nozzles, achieving simple structure and high performance. Good, the effect that meets the requirements of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

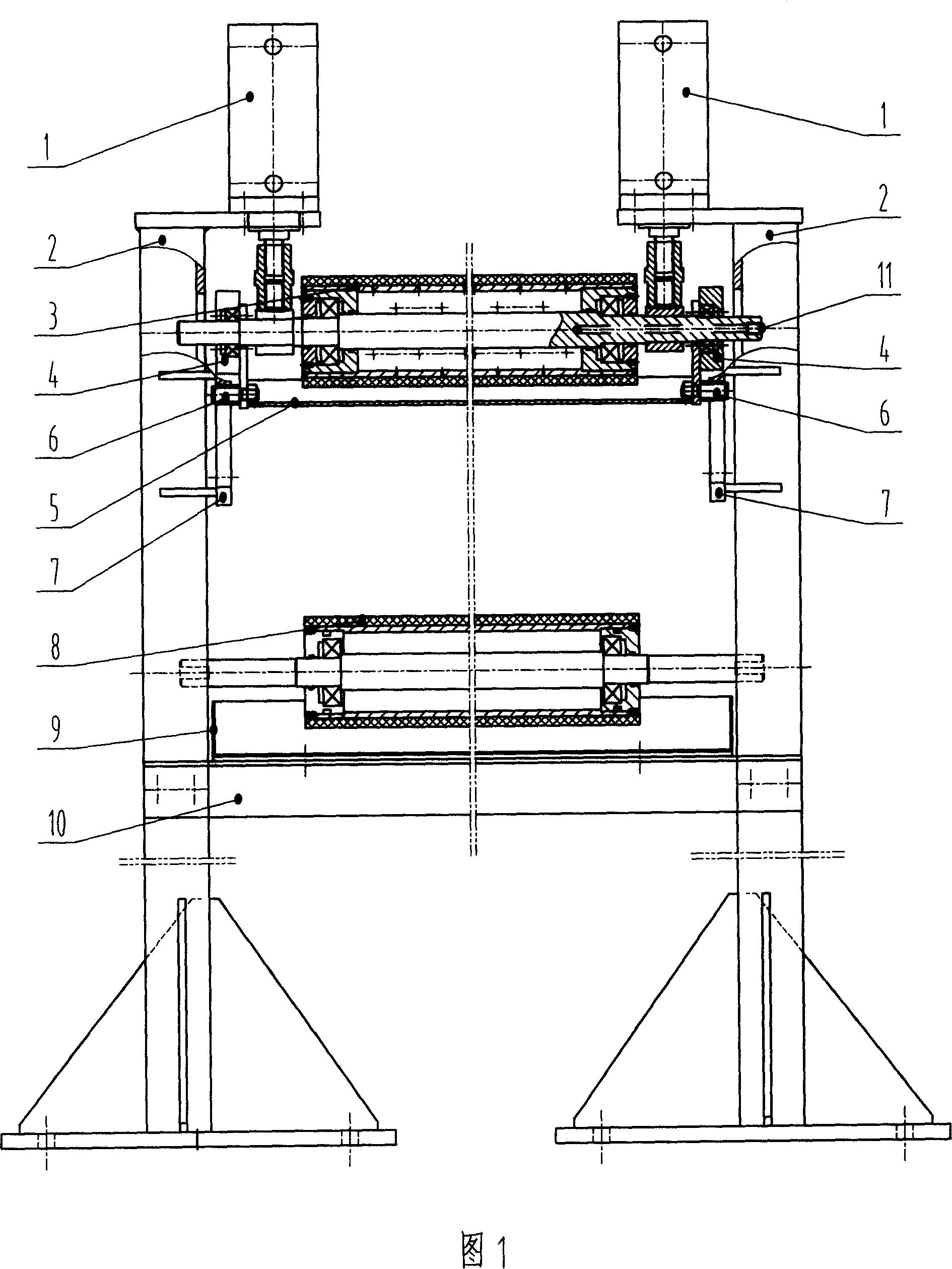

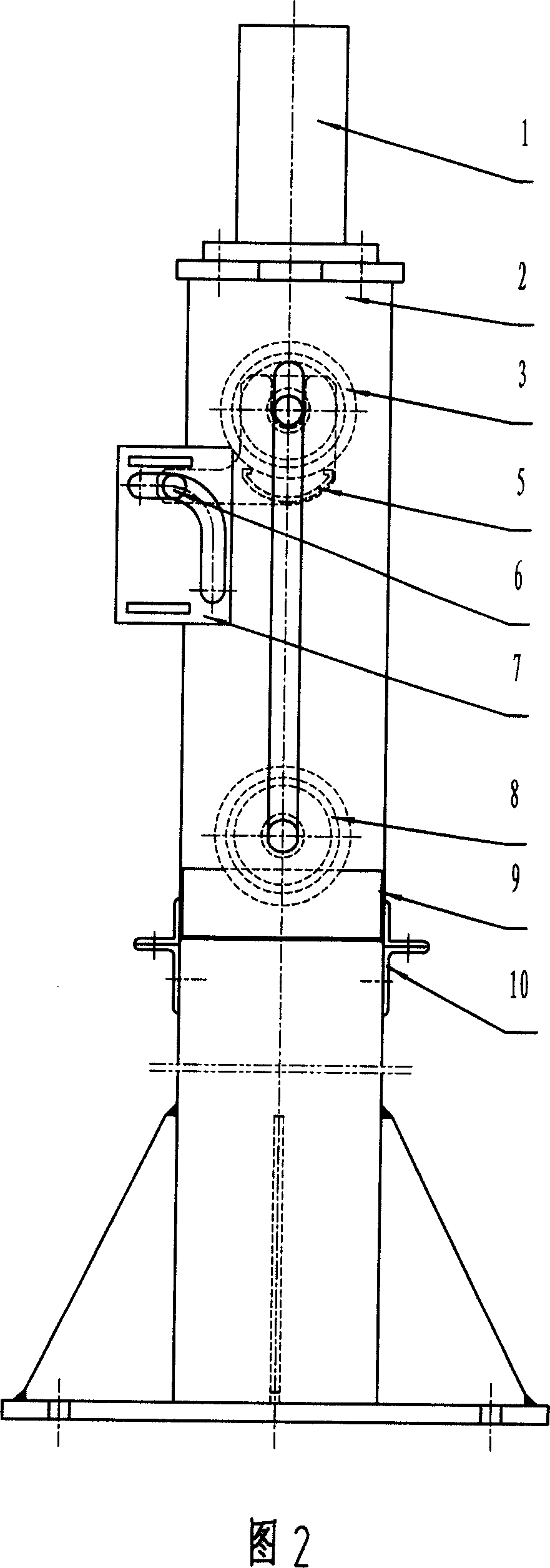

[0010] It can be seen from Fig. 1 and Fig. 2 that a silicone oil coating device for a conveyor belt plate vulcanizer includes a frame 2 on which a working cylinder 1, a seepage-soaked pressure roller 3, a immersion-type idler roller 8, silicone oil The storage tank 9 and the frame 2 are provided with a linear guide rail for the seepage-wetting pressure roller 3 to move up and down under the action of the working oil cylinder 1 .

[0011] In order to prevent pollution of equipment and products, the present invention is provided with a swinging silicone oil receiving groove 5 under the seepage-wetting pressure roller 3, and the two end plates of the swinging silicone oil receiving groove 5 are bolted to the leakage-wetting pressing roller. On the bearing housing 4 where the roller 3 rotates, a crankshaft 6 with a rolling sleeve is fastened on the ears of the two end plates, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com