Temperature equality device and temperature equality method in glass forming

A glass forming and uniform technology, applied in glass forming, glass forming, glass manufacturing equipment and other directions, can solve the problems of uneven thickness, uneven local temperature, and difficulty in forming, to improve quality and yield, reduce Effects of thickness and curvature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

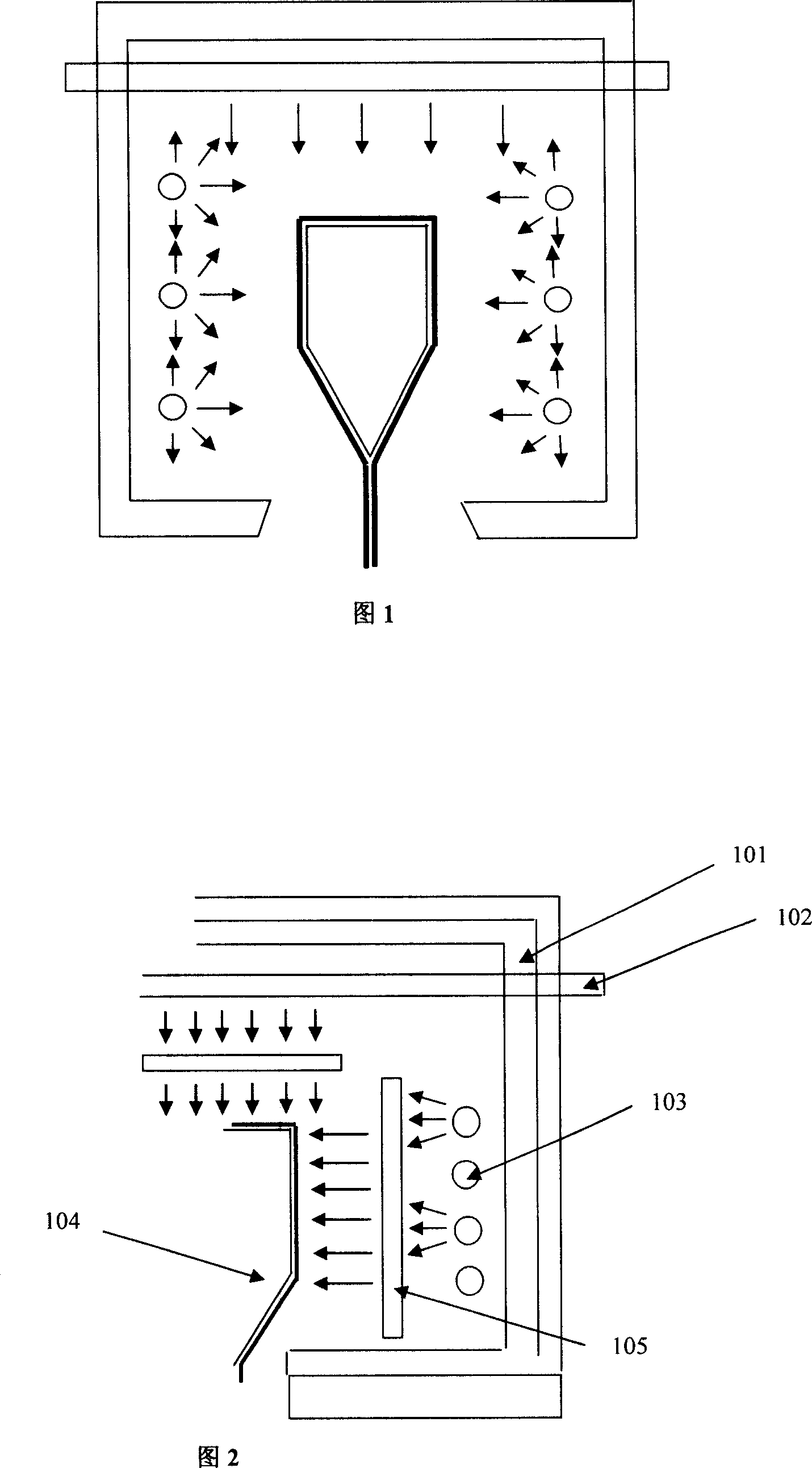

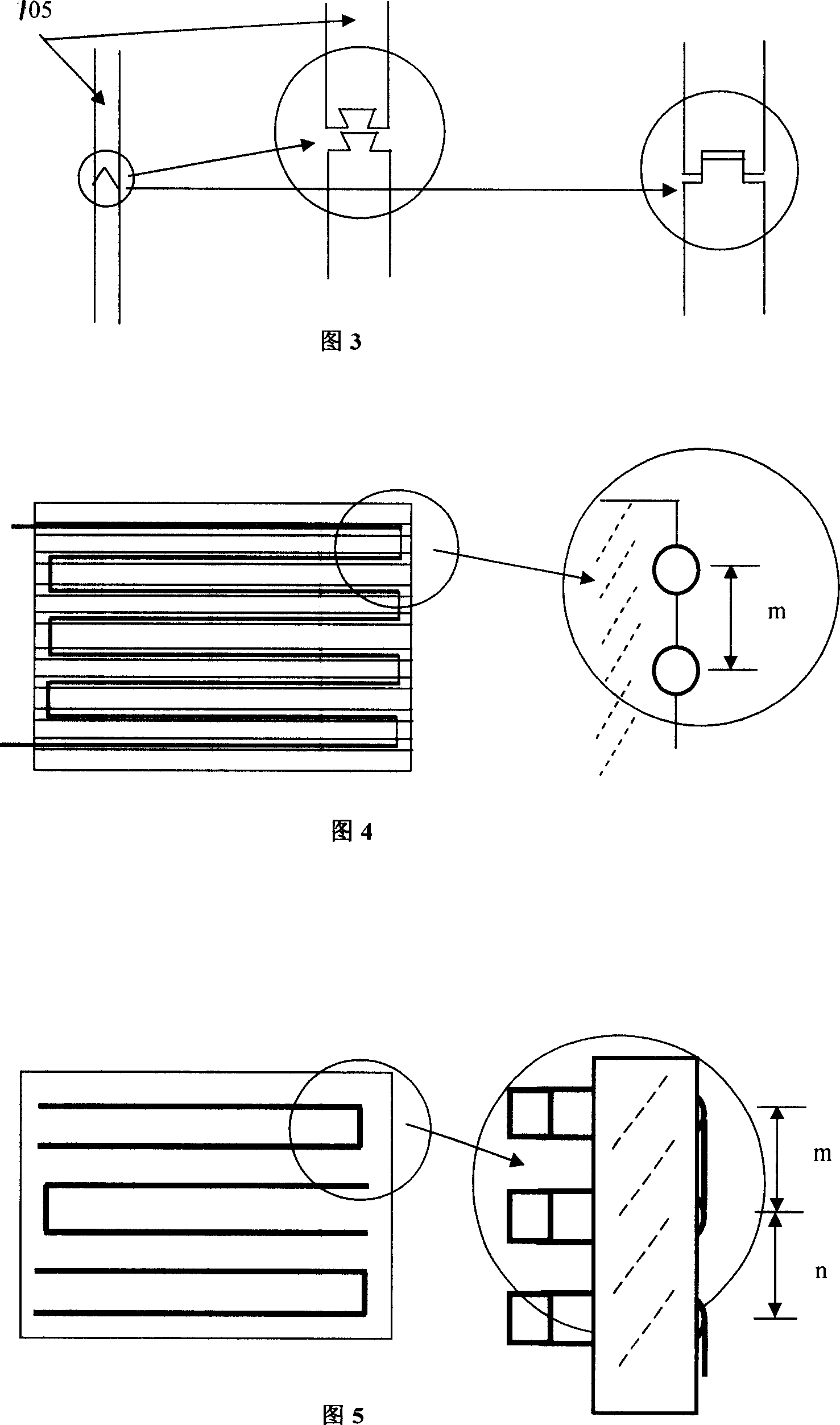

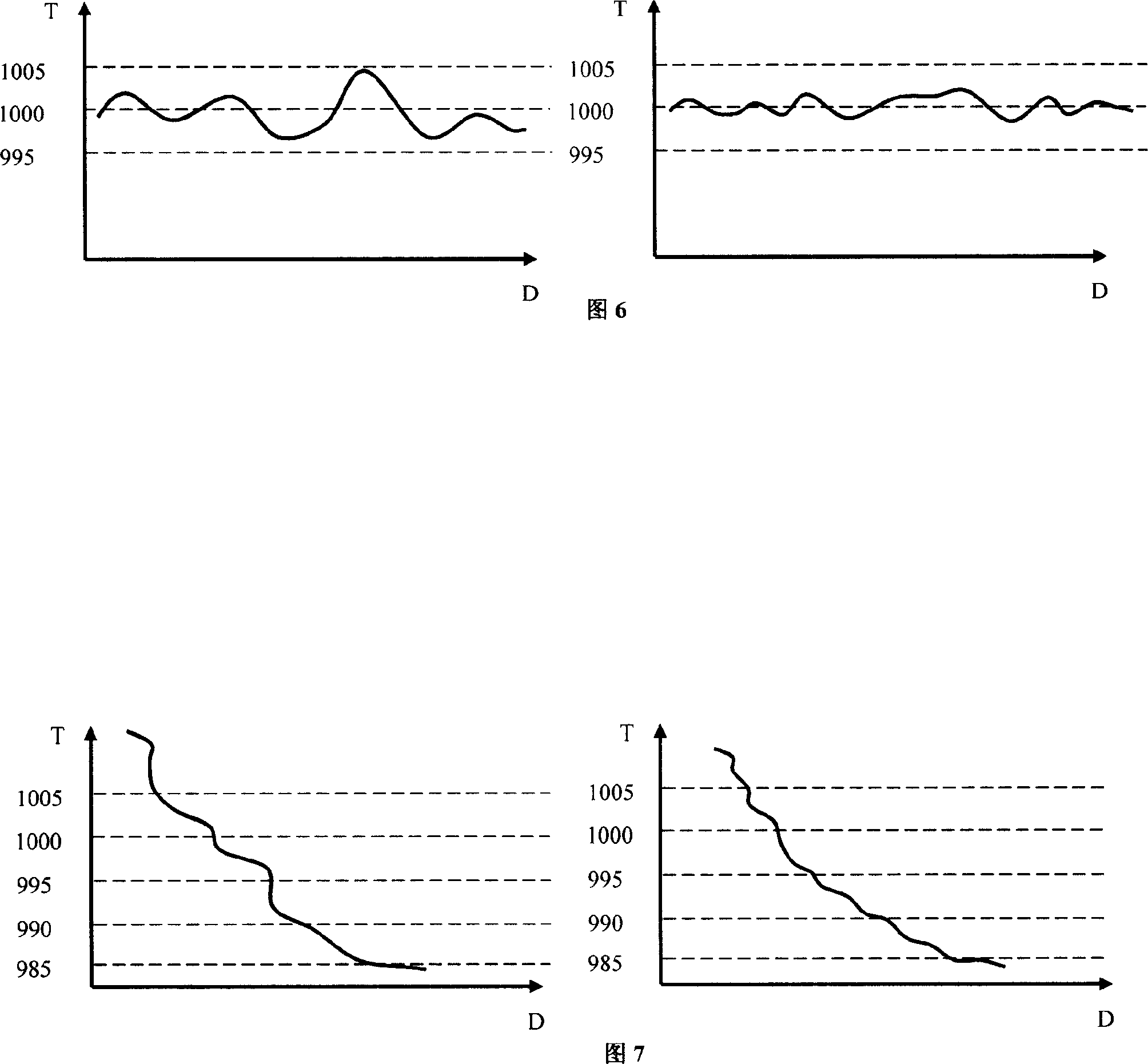

[0026] As shown in Figure 2, the utility model includes a forming body 104 formed by molten glass overflowing on it, a heating forming space formed by a top heating element 102 and a side wall heating element 103 arranged outside the forming body 104, and a heating forming space arranged on the top of the forming body 104. The thermal insulation part 101 outside the heating element and the side wall heating element is provided with a temperature uniform device 105 between the molding body 104 and the top heating element 102 and the side wall heating element 103, and its function is to collect the thermal energy radiated to the molten glass, and The molten glass is heated in the form of surface radiation, so that the glass flow can obtain a relatively uniform temperature; the temperature uniform device 105, that is, the uniform temperature equipment 105, is a silicon carbide uniform temperature plate, which seals the molded body 104 in the internal space, and the top heating elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com