Ultraviolet-resistant coating composition and ultraviolet-resistant thin film

An anti-ultraviolet and composition technology, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve problems such as light reflection color difference, light reflectance decrease, polymer resin yellowing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

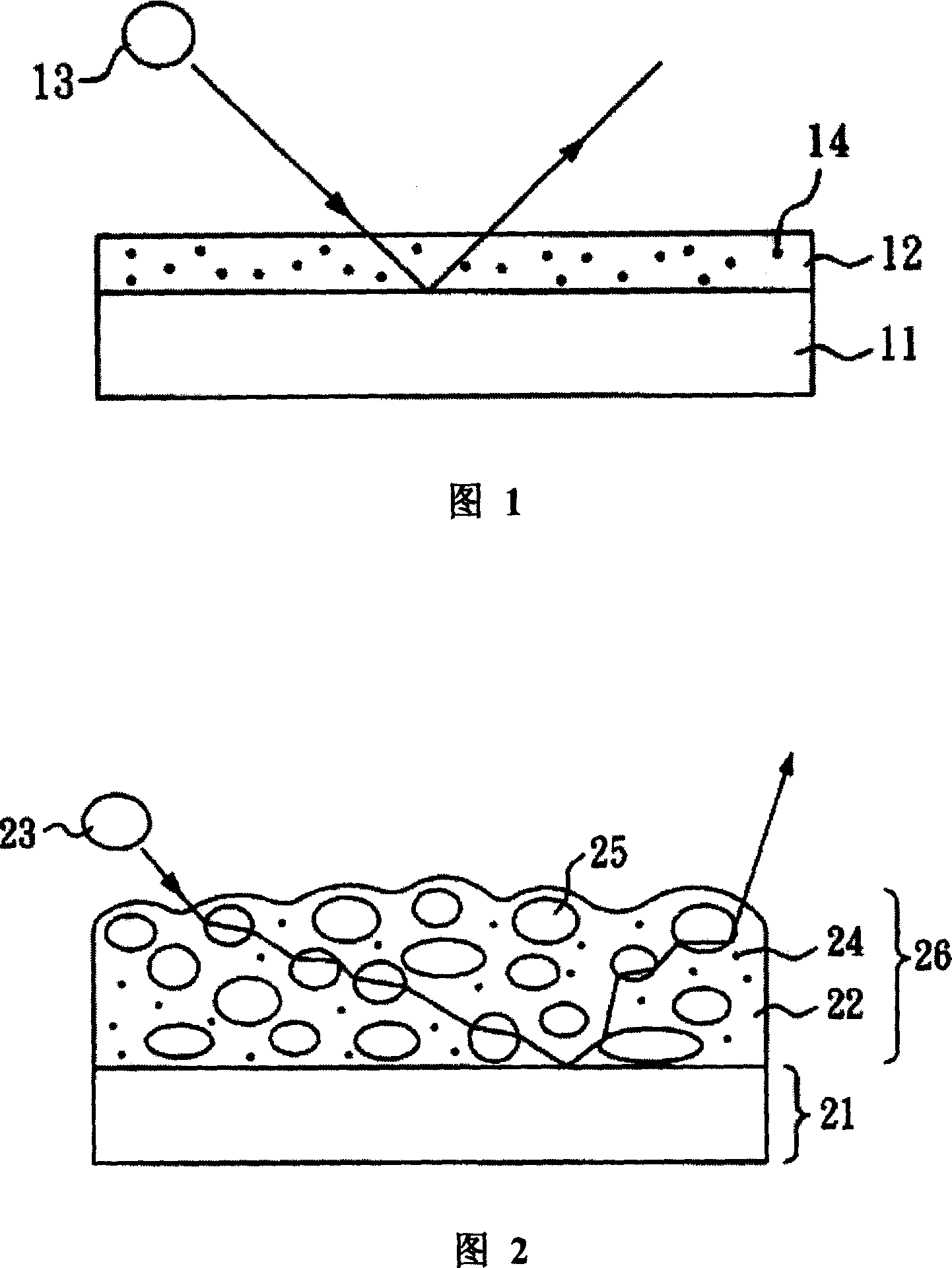

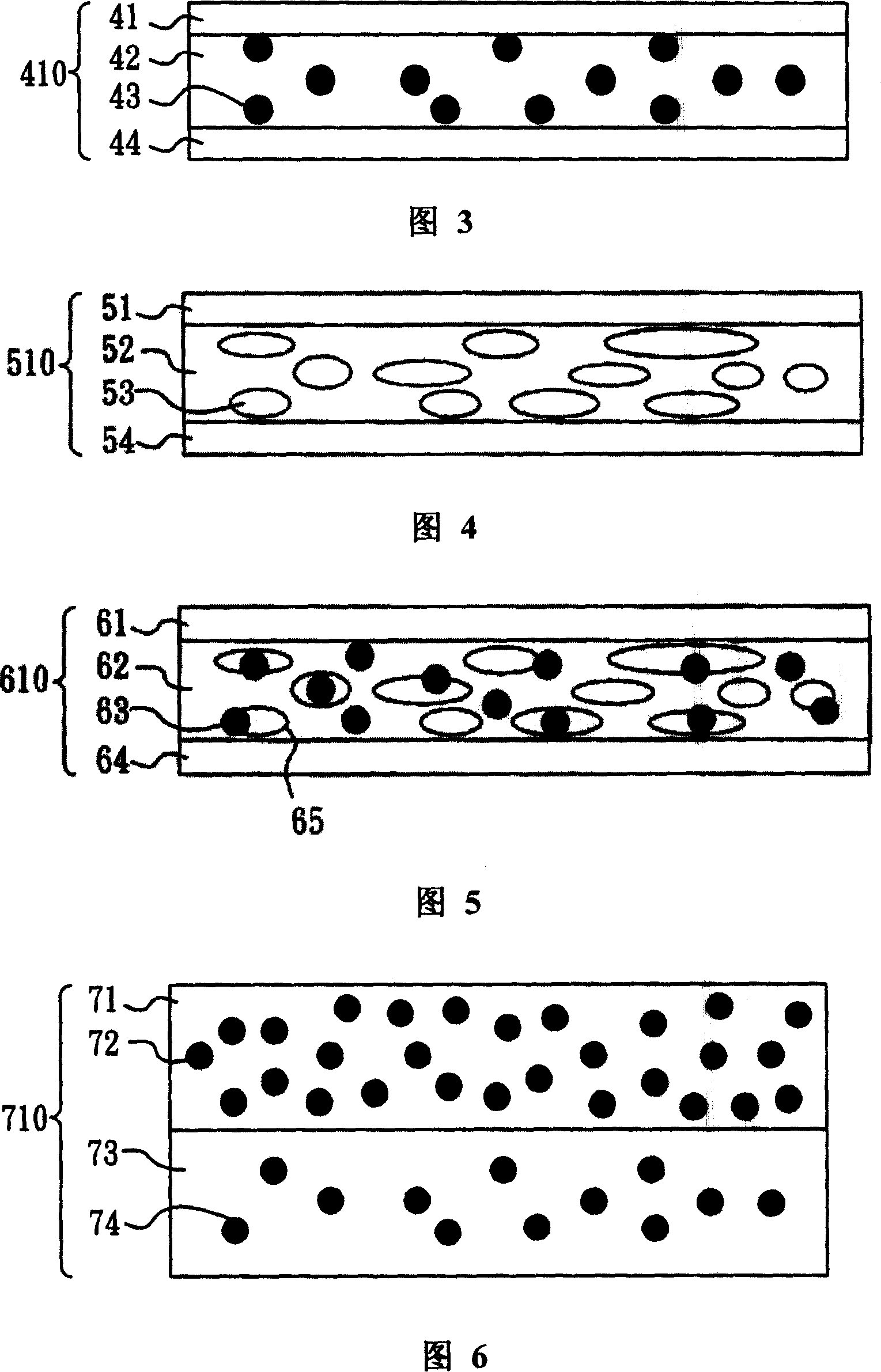

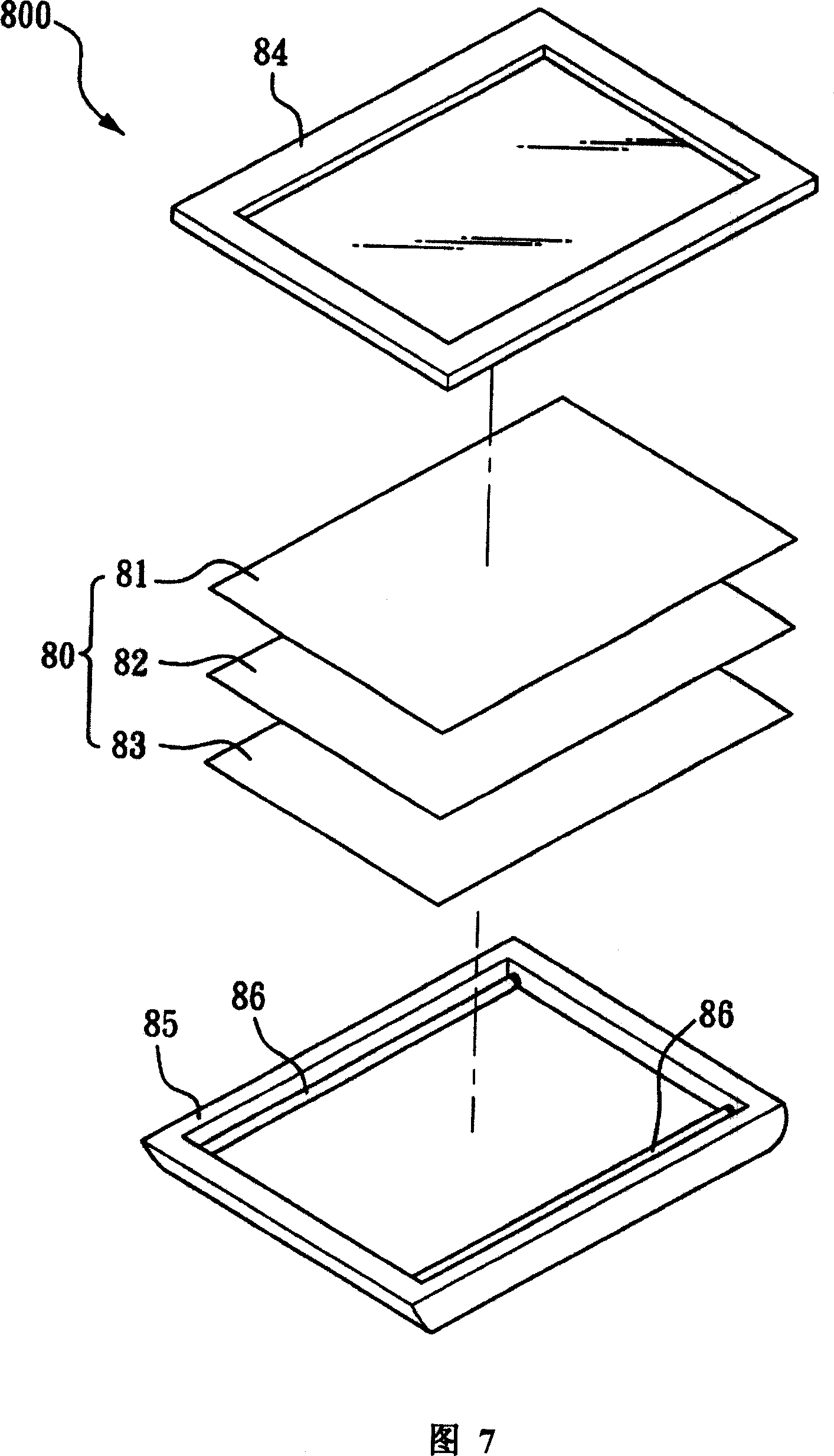

Image

Examples

Embodiment 1

[0122] Apply the anti-UV coating composition A to the reflective sheet ux-150 with RDS applicator stick #16 (film thickness of 150 μm, Teijin-Dupont Co., Ltd.), dried at 100°C for one minute, and a coating film of about 10 μm can be obtained after drying, with a total film thickness of about 160 μm. After standing for seven days, the optical properties were measured. 〖QUV (UVB-313nm) irradiation for 500 hours〗, and do weather resistance test.

Embodiment 2

[0124] Apply the anti-UV coating composition A to the reflective sheet ux-188 with RDS applicator #16 (film thickness of 188 μm, Teijin-Dupont Co., Ltd.), dried at 100°C for one minute, and a coating film of about 10 μm can be obtained after drying, with a total film thickness of about 198 μm. After standing for seven days, the optical properties were measured. , and do a weathering test.

Embodiment 3

[0126] Apply the anti-UV coating composition A to the reflective sheet ux-225 with RDS applicator stick #16 (film thickness of 225 μm, Teijin-Dupont Co., Ltd.), dried at 100°C for one minute, and a coating film of about 10 μm can be obtained after drying, with a total film thickness of about 235 μm. After standing for seven days, the optical properties were measured. , and do a weathering test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com