Air supplemental heat transfer engine

A technology of engine and gas storage, which is applied in open gas positive displacement engine factories and other directions, and can solve problems such as discontinuous movement of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

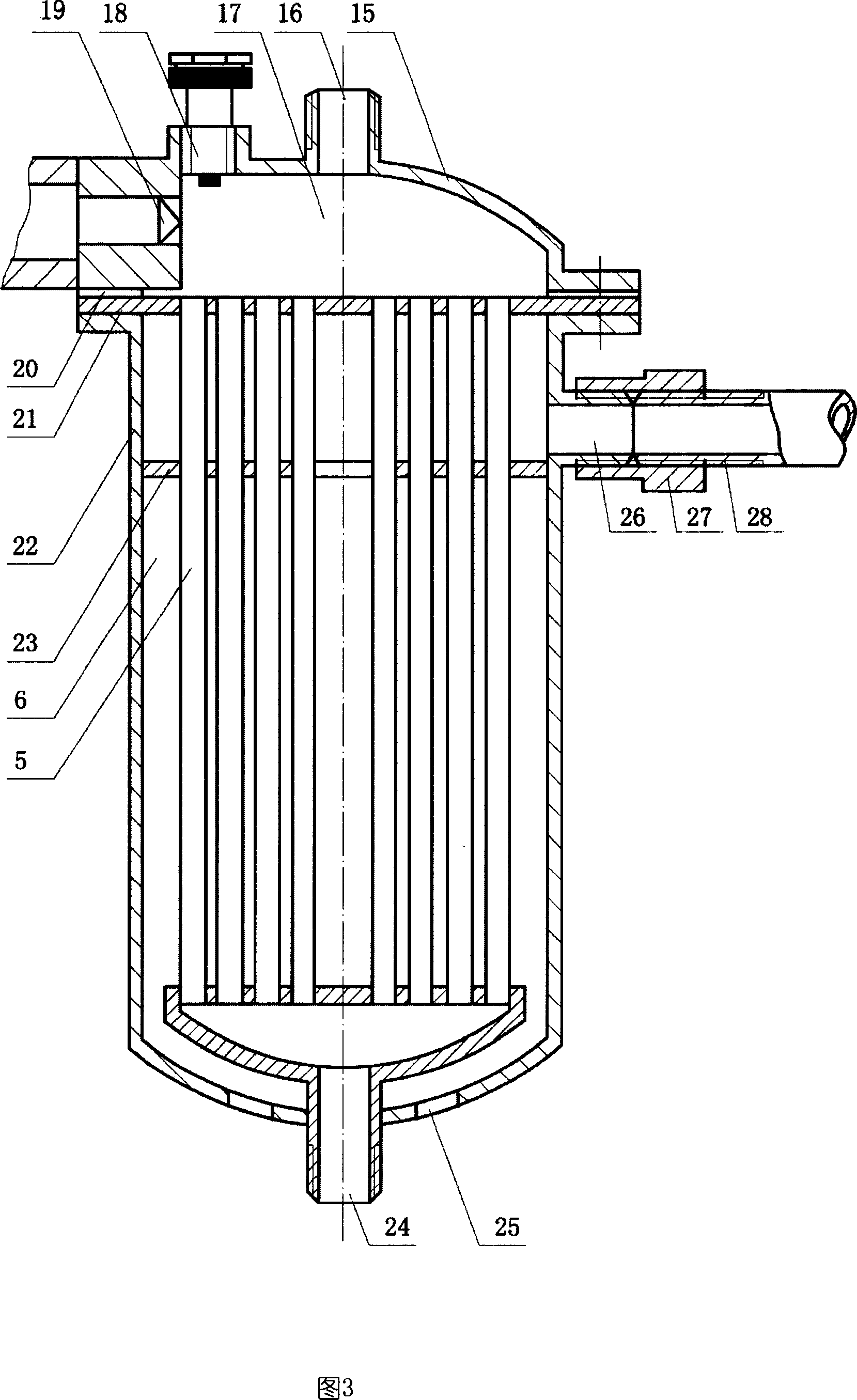

[0060] The microcomputer-controlled air distribution mechanism arranged on the hot cylinder head is shown in Figure 6, and the structure of the intake valve is shown in Figure 7. When the hot cylinder 1 requires intake air, the microcomputer 59 controls the coil 57 to open the intake valve 3 (sheet The right end of shape gas valve 3 leaves valve port), and gas enters in the thermal cylinder by inlet 34 and valve port. Electric current stops in coil 57 under the control of microcomputer 59 when needing to close intake valve, and now the rebound of spring 67 pushes down the right end of sheet intake valve rapidly through electromagnet 68 and pull bar 56, and blocks valve port.

[0061] The structure of the exhaust valve is as shown in Figure 8. When the hot cylinder needs to be exhausted, the microcomputer 59 controls the coil 53 to open the exhaust valve 4. When the exhaust valve needs to be closed, the electric current of the coil 53 under the control of the microcomputer 59 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com