Water-cooled reactor for converting of integrated gate commutated thyristor

A technology of commutating thyristors and water-cooled reactors, which is applied in the direction of transformer/inductor cooling, etc., can solve problems such as IGCT component damage, and achieve the effects of improving work performance, ensuring safe work, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

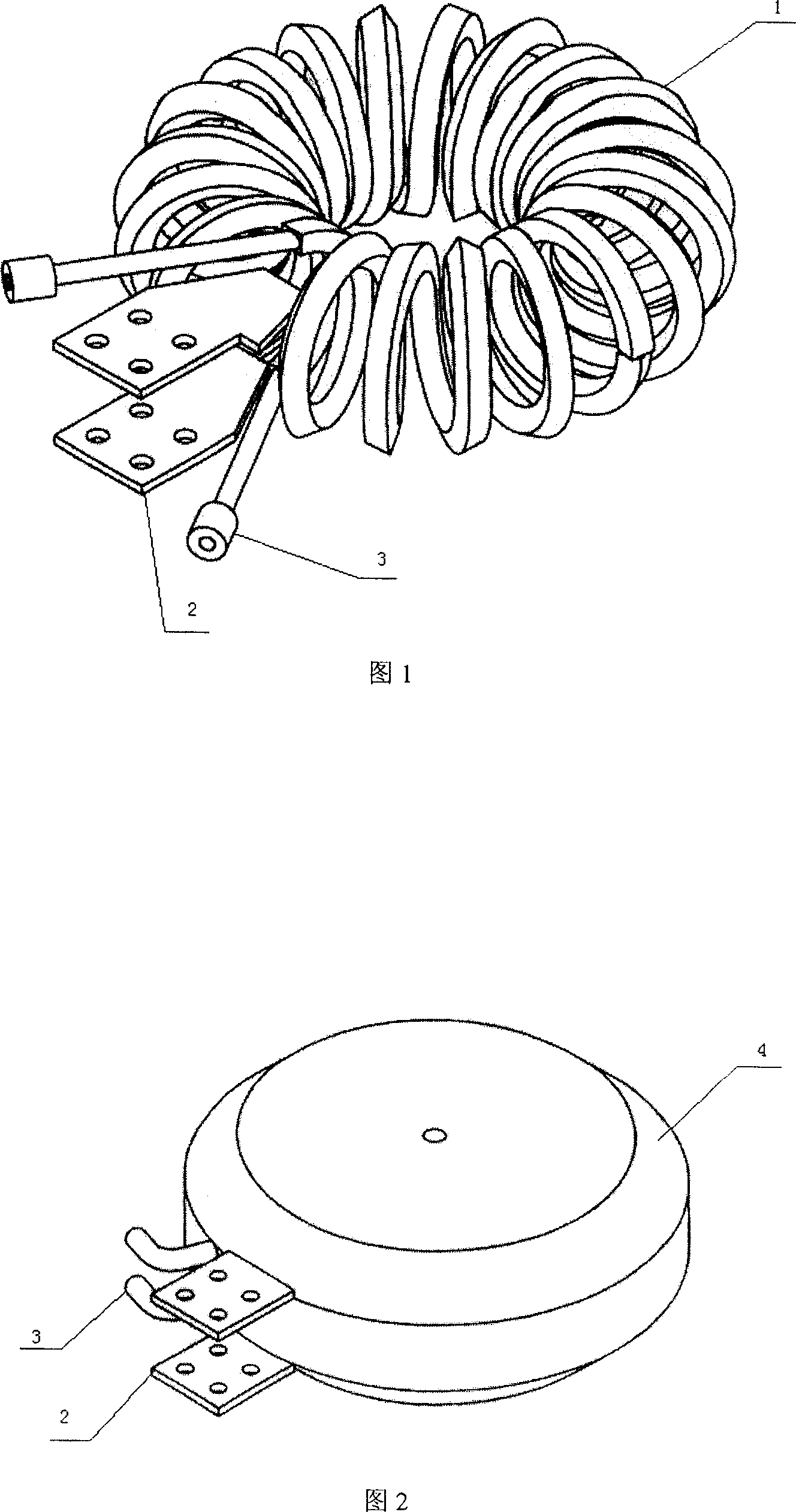

[0010] Figures 1 and 2 show an embodiment of the present invention. Among them, the hollow special-shaped copper tube is processed into a reactor in which each turn is circular and spirally wound into a ring shape. The two ports of the reactor formed by welding two nozzles on the hollow special-shaped copper tube are used as the water inlet and outlet of the water-cooled reactor. Two bus bars are respectively welded in parallel on both ends of the hollow shaped copper tube. The surrounding of the spirally-circulated hollow special-shaped copper pipe is cast with epoxy resin into a circular plane with the same radius up and down, the middle part is a cylinder with a radius of 3-10 cm larger than the upper and lower circular planes, and a circular hole is provided in the center for easy installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com