Semiconductor device and manufacturing method for the same

一种制造方法、半导体的技术,应用在半导体/固态器件制造、半导体器件、半导体/固态器件零部件等方向,能够解决附着性差、附着性易受环境条件的影响、树脂膜易脱落等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

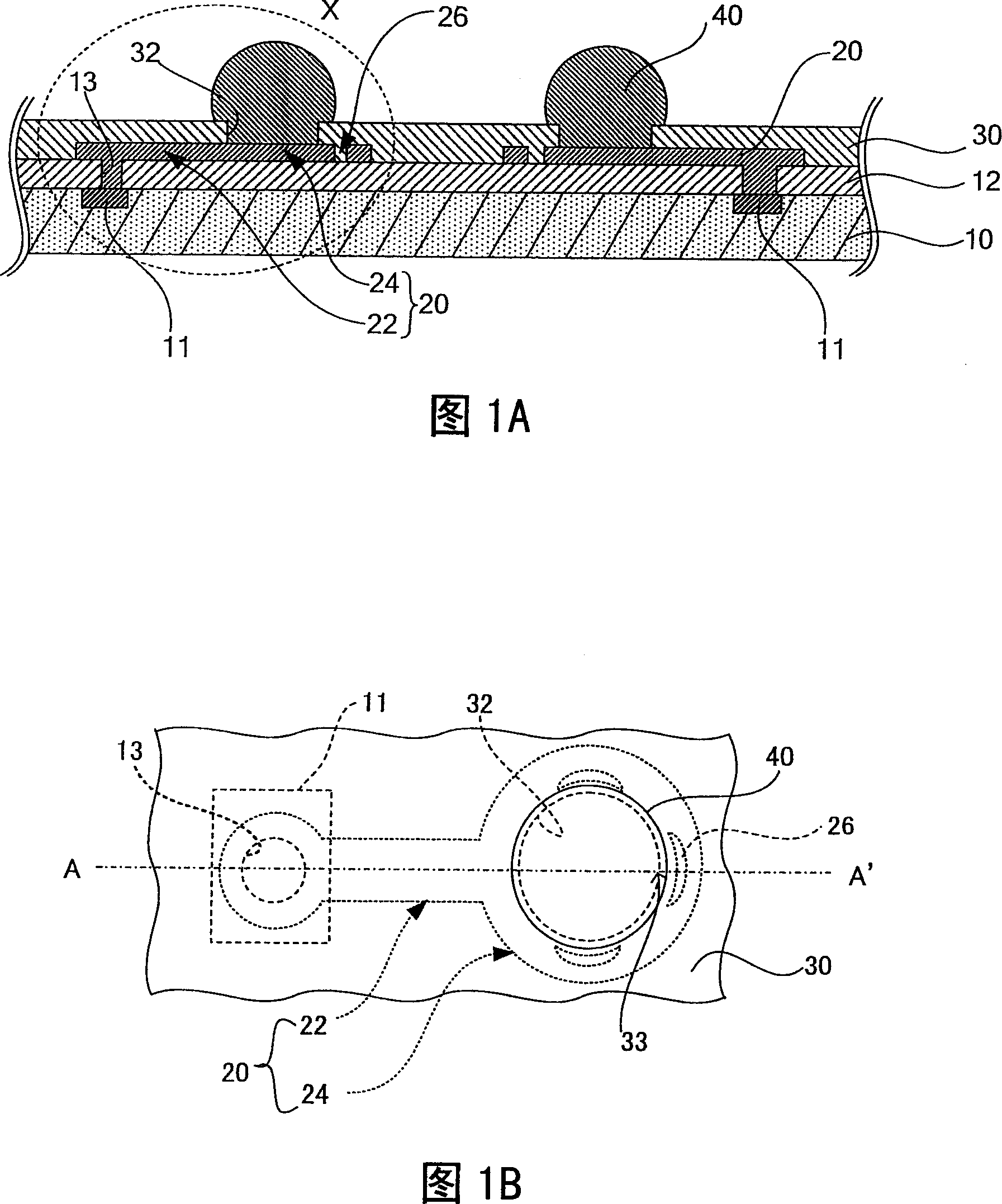

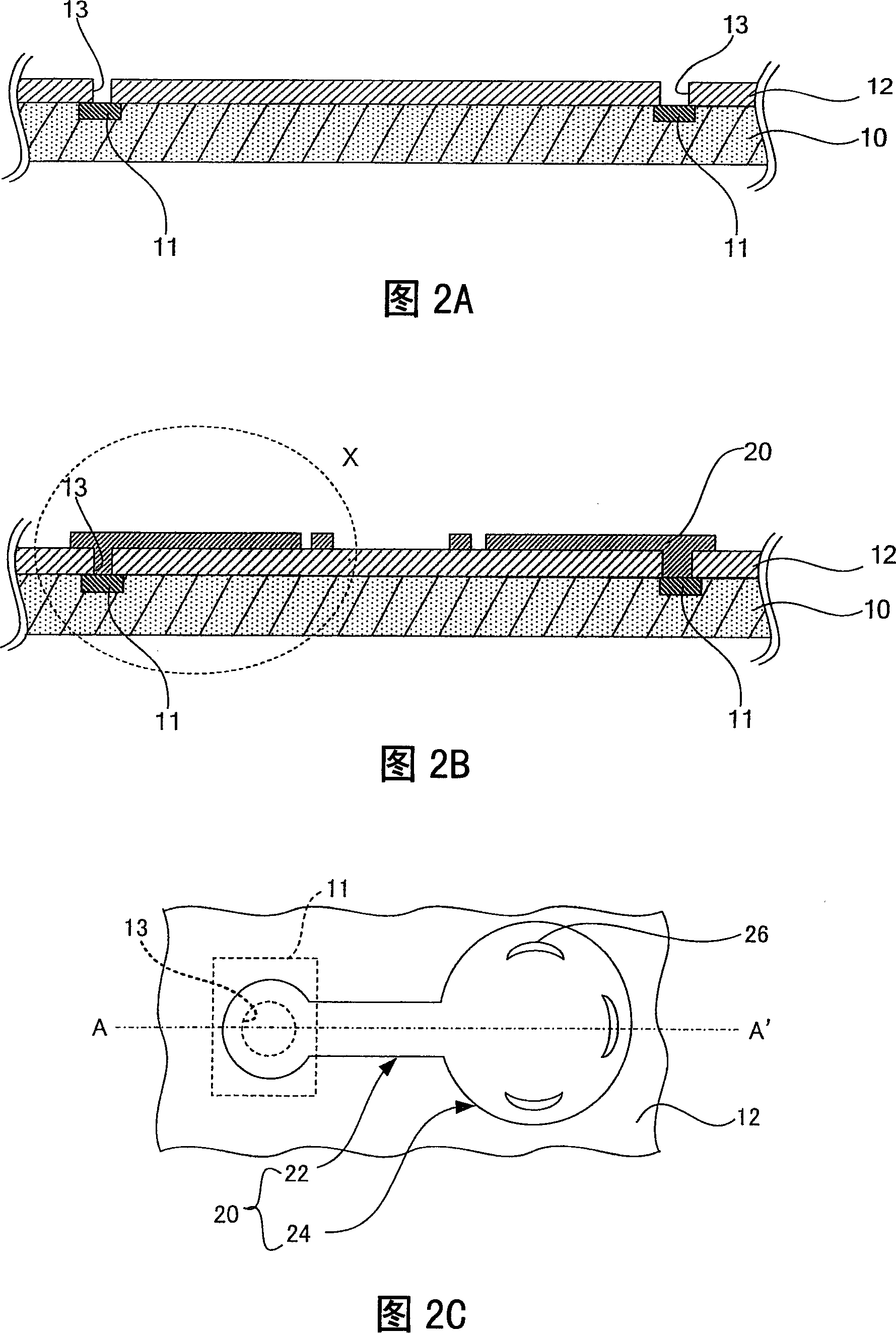

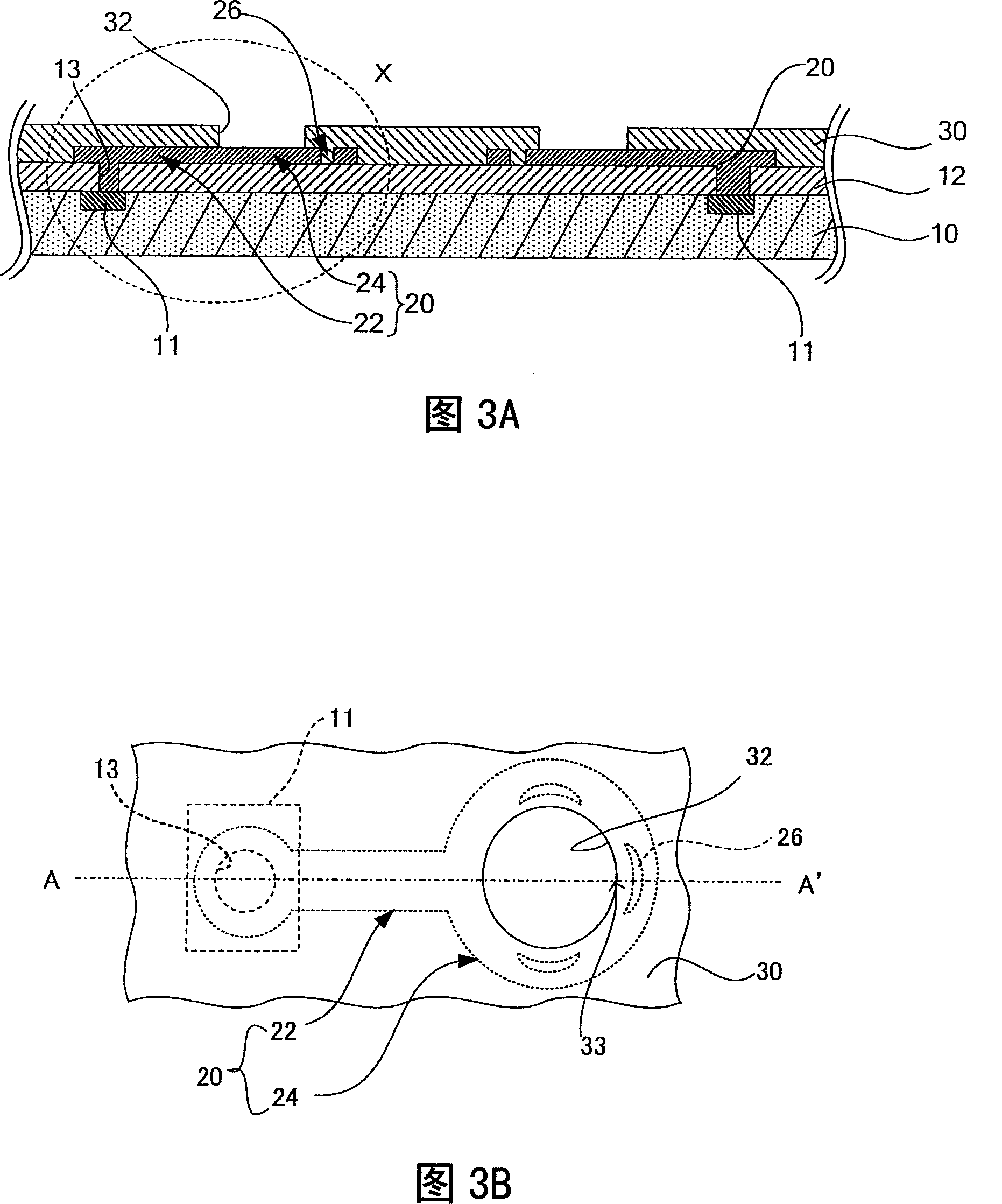

[0035] A first example of the semiconductor device of the present invention is shown in FIGS. 1A and 1B. FIG. 1A is a cross-sectional view along line A-A' of FIG. 1B , and FIG. 1B is a top view of a portion "X" surrounded by a dotted line in FIG. 1A .

[0036] In the semiconductor device shown in FIG. 1A, an insulating film 12 made of, for example, polyimide resin is formed on a silicon wafer 10 having an Al pad 11 serving as the above-mentioned semiconductor substrate. The insulating film 12 is provided in such a manner as to avoid the space above the Al pad 11 where the connection hole 13 is to be provided.

[0037] A conductive layer (or interconnection) 20 made of copper is provided on the surface of the insulating film 12 and fills the connection hole 13 . The A1 pad 11 and the conductive layer 20 are bonded together via the connection hole 13 . Conductive layer 20 is formed of interconnection portion 22 and pad portion 24 . As shown in FIG. 1B , three via holes 26 pen...

example 2

[0062]A second example of the semiconductor device of the present invention is shown in FIGS. 4A and 4B. In each drawing, the upper part shows a top view of the semiconductor device, and the lower part shows a cross-sectional view along line B-B' of the top view.

[0063] In the semiconductor device shown in FIG. 4A , there are provided four through holes 26 arranged at substantially equal distances from the end of the exposed opening (ie, the end 33 of the resin film opening 32 ), The exposure opening occurs over at least a portion of the pad portion 24 of the conductive layer 20, and the four via holes 26 are spaced apart from each other by substantially equal distances.

[0064] Note that, when the semiconductor device shown in FIG. 4A is manufactured, in the above-mentioned conductive layer forming step, four via holes 26 are formed in the conductive layer 20 in the following manner as viewed from above the horizontally divided silicon wafer 10: four vias The shapes of th...

example 3

[0066] A third example of the semiconductor device of the present invention is shown in FIG. 5 . FIG. 5 is a plan view of a pad portion of the semiconductor device showing the configuration of via holes provided on the pad portion.

[0067] As shown in FIG. 5 , in Example 3, eight via holes 27 penetrating the conductive layer 20 are provided. When viewed from above the horizontally divided silicon wafer 10, the eight through holes 27 have substantially the same circular shape, and their sizes are also substantially the same. In addition, the eight through holes 27 are arranged at substantially equal distances from the end of the exposure opening (or, the end 33 of the resin film opening 32 ) that appears over at least a part of the pad portion 24 of the conductive layer 20 . , and the eight through holes 27 are spaced from each other at substantially equal distances.

[0068] As described above, in Example 3, since the eight through holes 27 are symmetrical about the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com