Reorganizing and outfitting operation method and safety system for locomotive warehouse

A safety system and locomotive technology, applied in railway signaling and safety, railway car body components, in-station locking devices, etc., can solve the problems of signal equipment rash, collision, railway traffic safety threats, etc., to reduce labor intensity and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

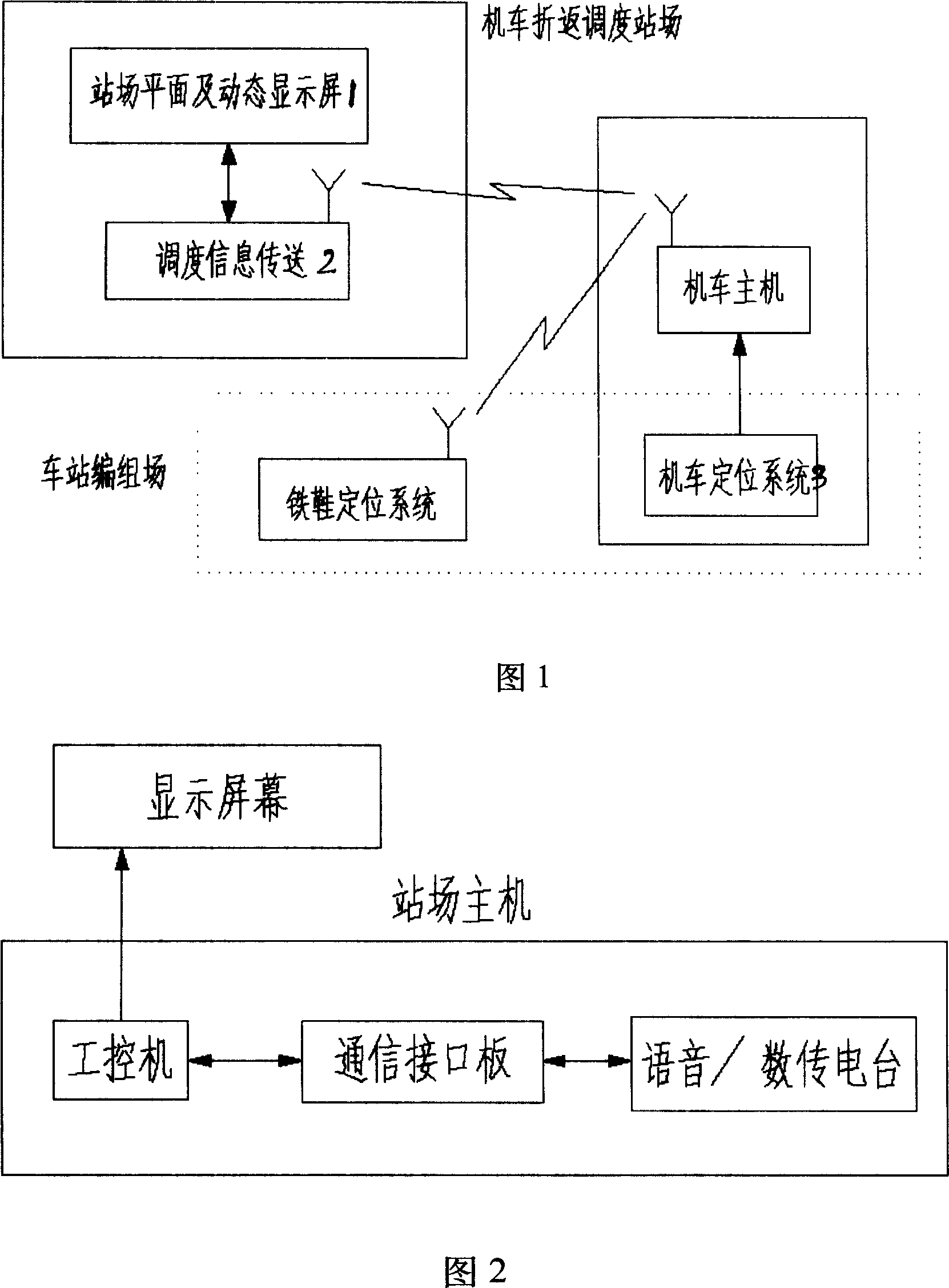

[0036] 1. The system structure is shown in Figure 1:

[0037] The maintenance operation safety system in the locomotive depot is mainly composed of station plane and dynamic display unit, dispatching information transmission unit, locomotive positioning system, iron shoe positioning system and other parts.

[0038] The locomotive positioning system displays, warns, prompts, and takes monitoring measures for the position and route status of various locomotives entering, docking, and leaving the station, and sends these information to the station plane and dynamic display screen through the locomotive host to display. The iron shoe positioning system sends the monitoring information of iron shoes to the locomotive main engine, prompts the corresponding voice information after being processed by the locomotive main engine, and sends the monitoring information to the station plane and dynamic display screen for display. The plane and dynamic display screens of the station process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com