Method for producing choles phase liquid crystal high-molecular optical reinforced film

A technology of cholesteric liquid crystals and liquid crystal polymers, which is applied in the field of preparation of cholesteric liquid crystal polymer light-enhancing films, and can solve the problems of cumbersome processes for cholesteric liquid crystal polymer light-enhancing films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

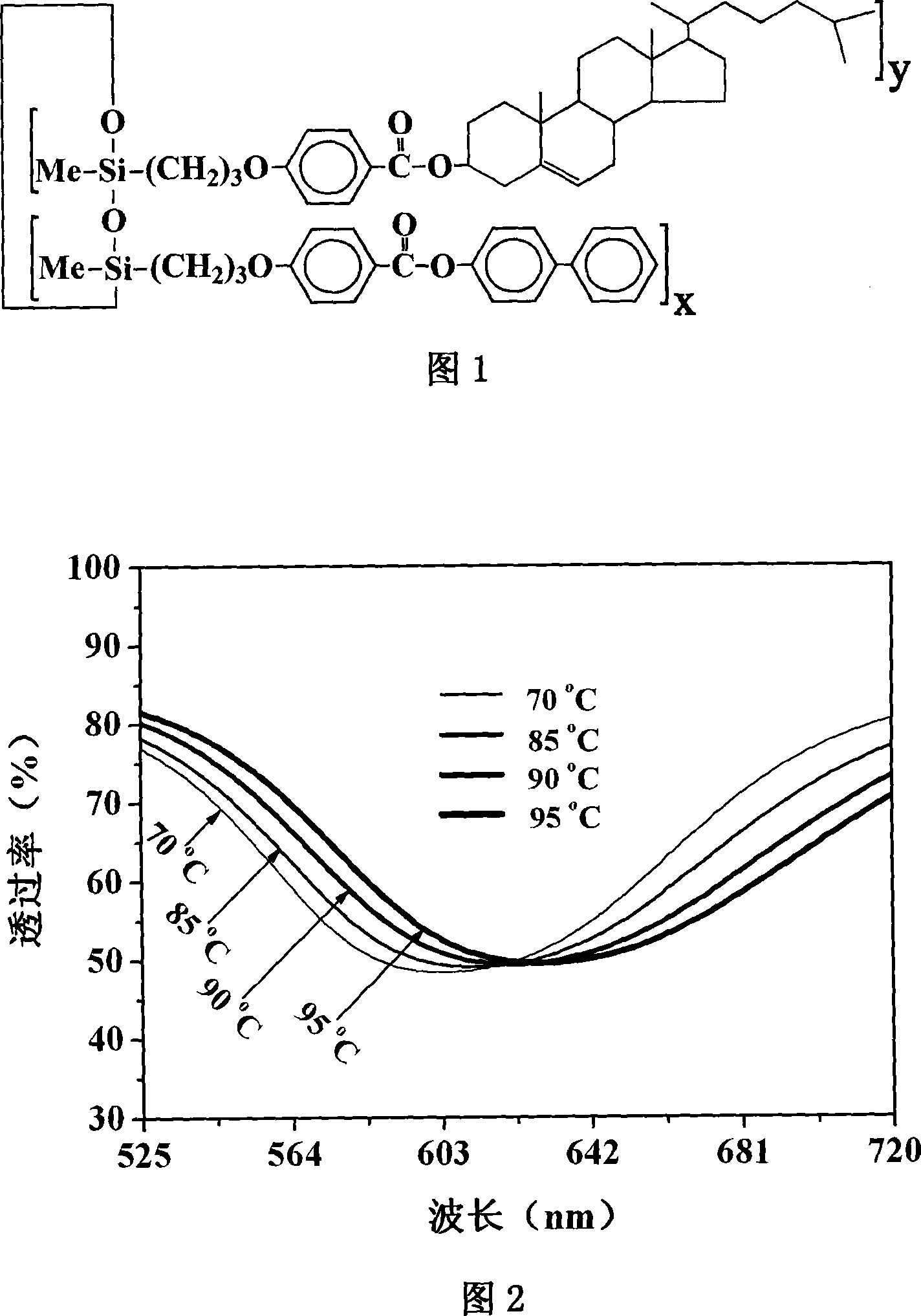

[0023] The cholesteric liquid crystal polymer used is shown in FIG. 1 .

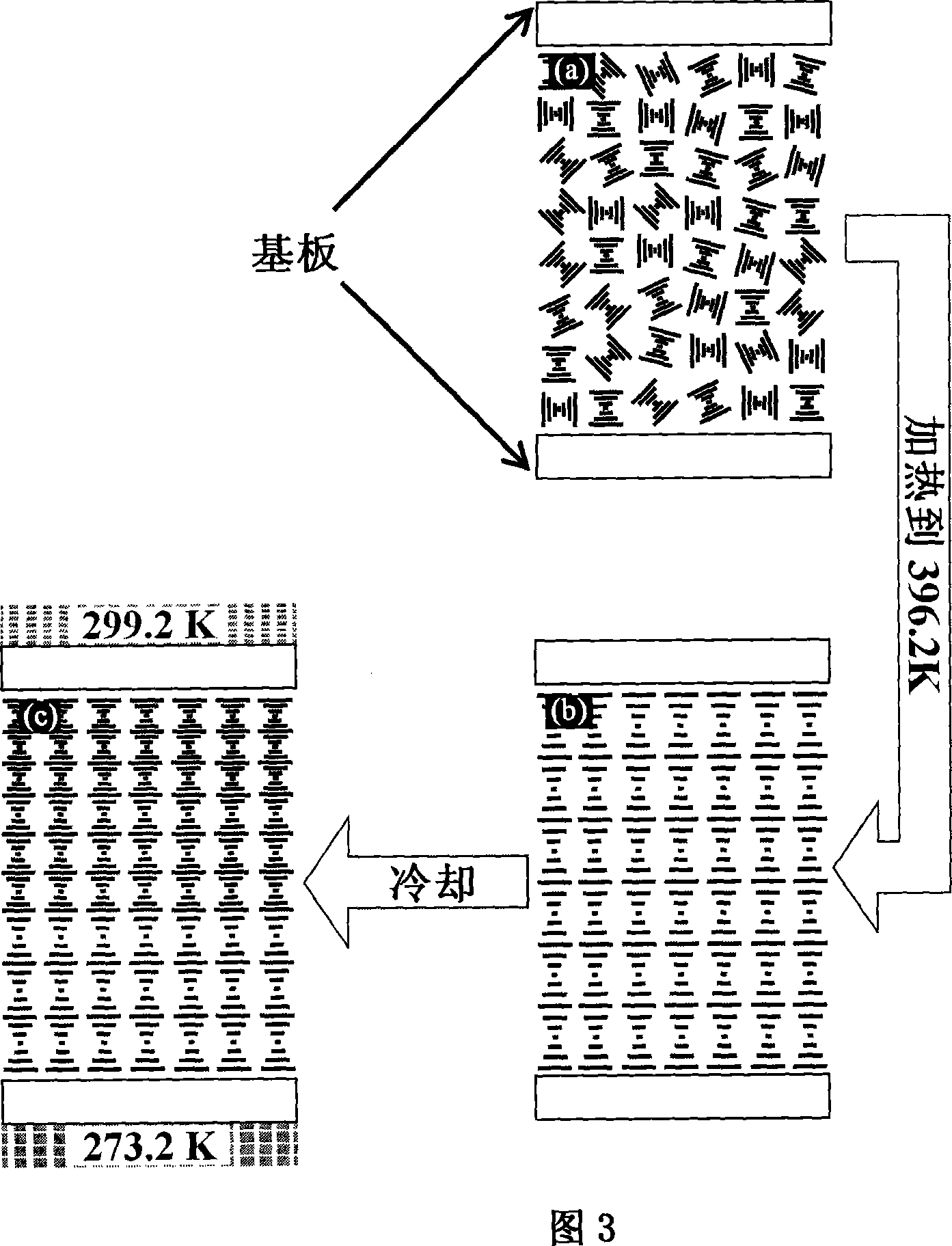

[0024] Fig. 2 is the transmission spectrum curves of the cholesteric liquid crystal polymer used in the present invention at different temperatures. It can be seen from the figure that the minimum transmittance wavelength (reflection wavelength) of the cholesteric liquid crystal polymer increases with the increase of temperature, so the pitch of the liquid crystal phase of the cholesteric liquid crystal polymer increases with the increase of temperature.

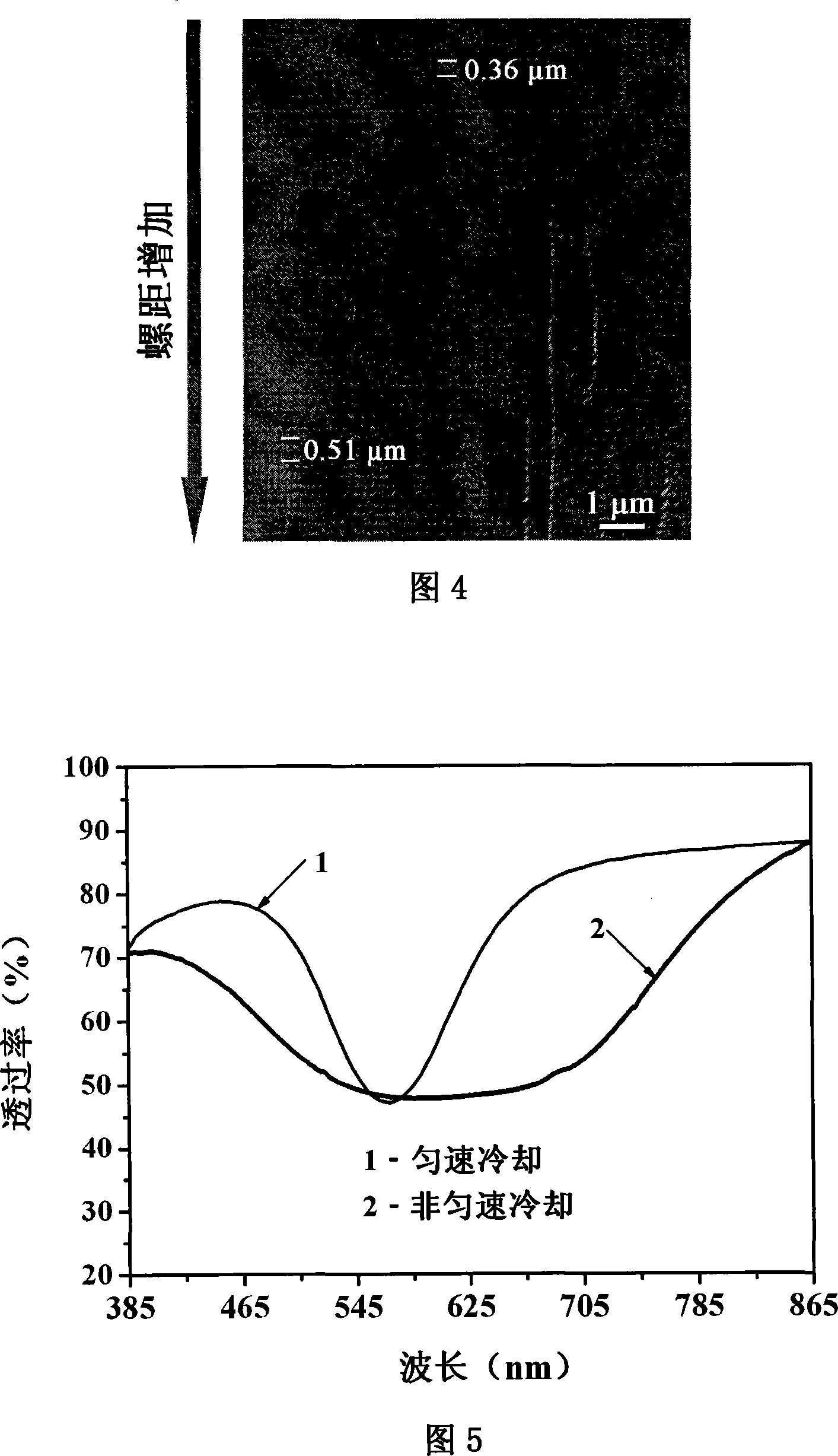

[0025] Fig. 3 is a simulation diagram of the principle of preparing a light enhancement film. The cholesteric liquid crystal polymer used is mixed with glass microspheres with a diameter of 20 microns, and then sandwiched between two layers of transparent plastic films whose inner surfaces have not been oriented. Prepared into a thin film, as shown in Figure 3(a). Then take 5Kmin -1The film is heated to 396.2K at a heating rate of 396.2K. Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com