Lake dredging bottom-mud dewatering integrated treatment technology

A treatment process and river dredging technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of numerous procedures, low production efficiency, impact on the environment, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

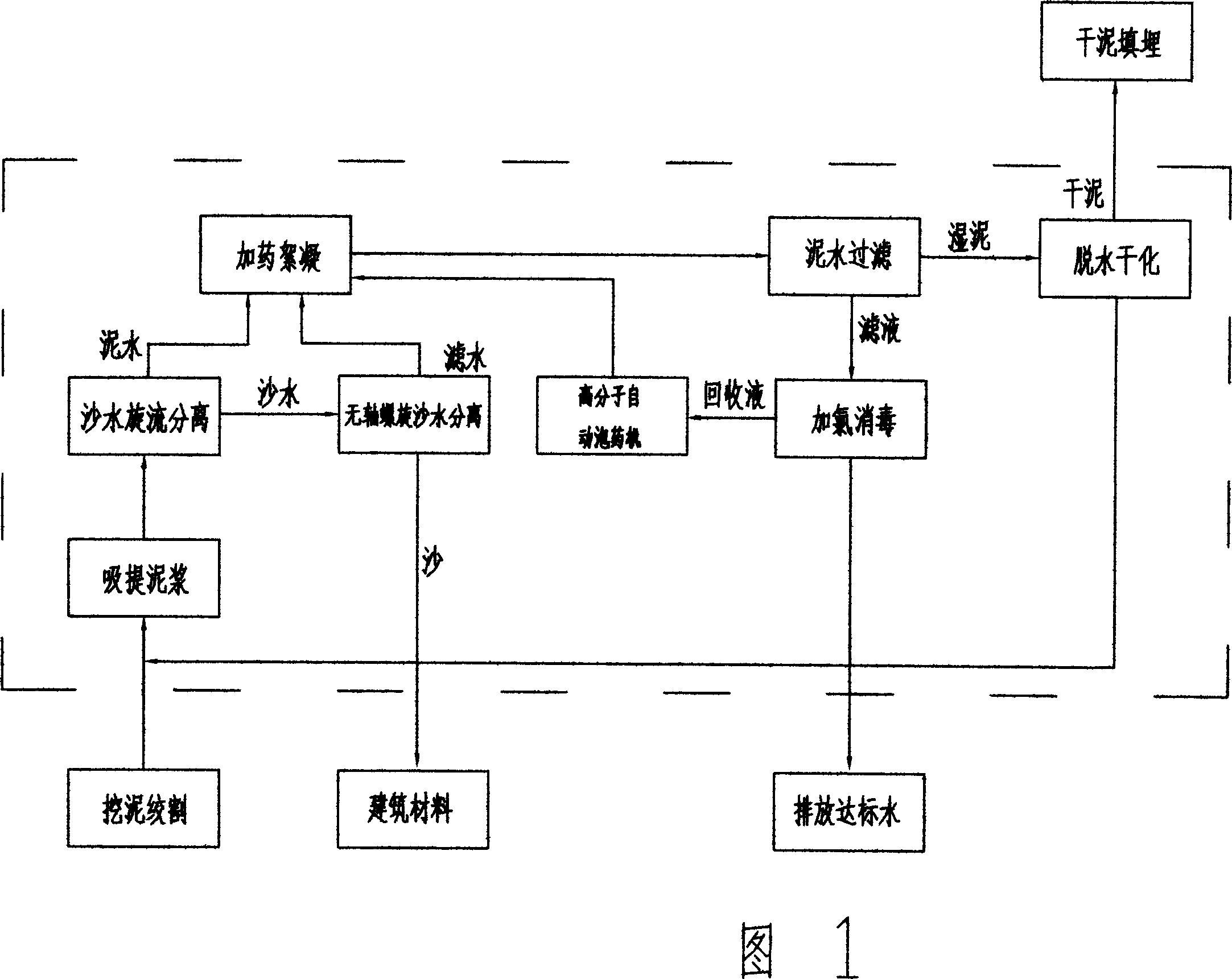

[0023] The dotted line in Figure 1 is part of the technological process realized on the dredger.

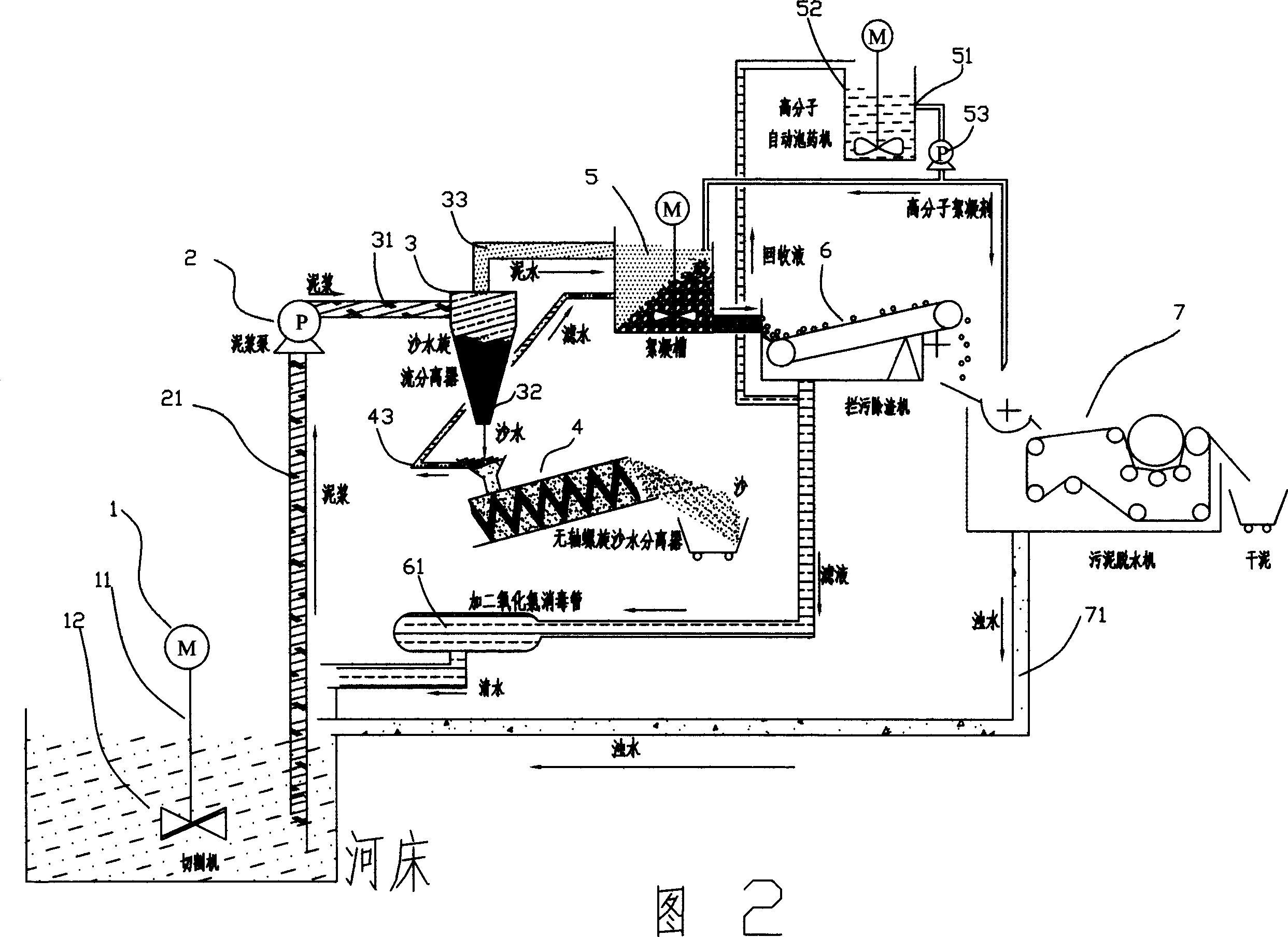

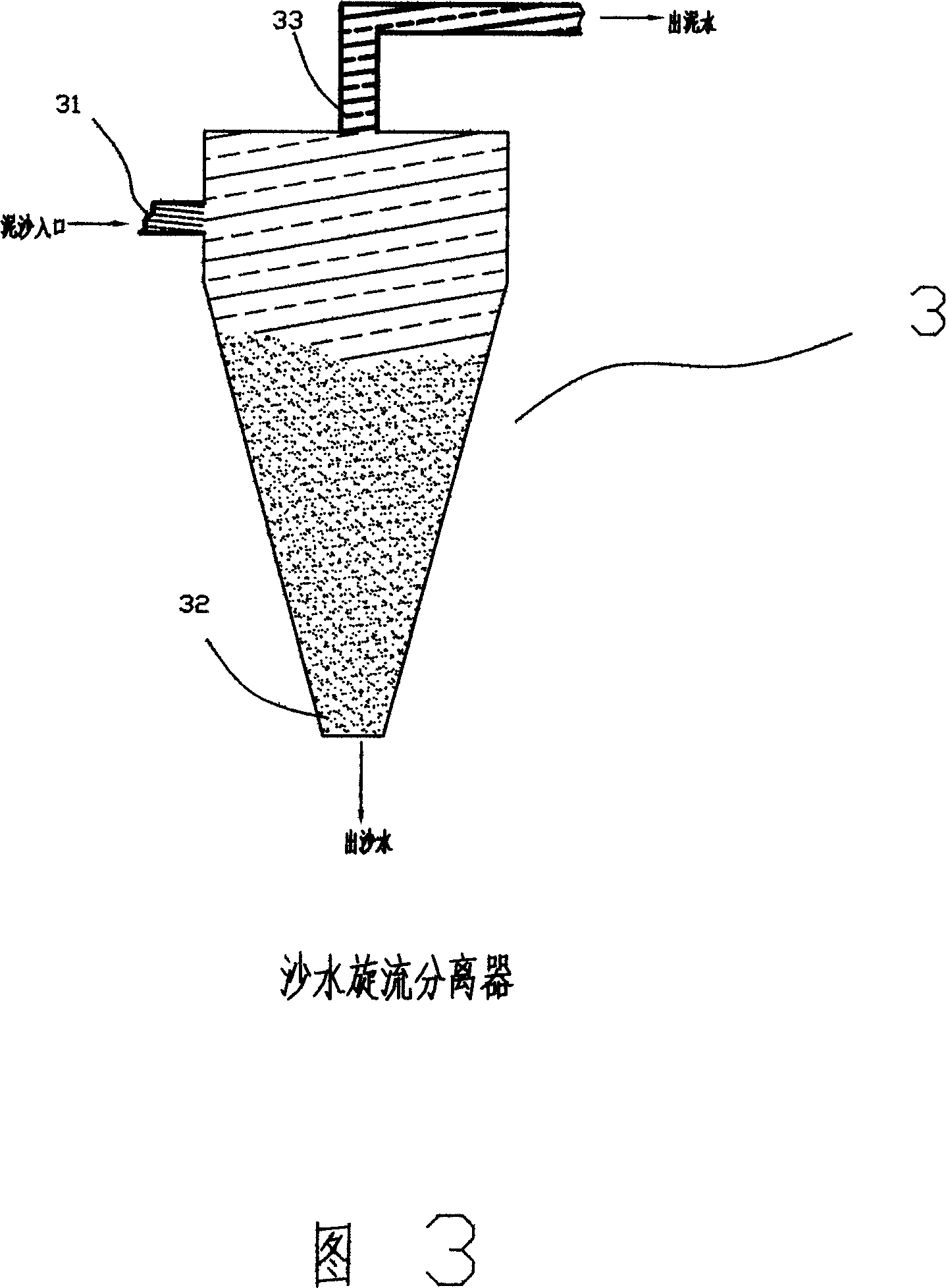

[0024] The specific process steps of the present invention will be described in detail below in conjunction with FIGS. 2 , 3 and 4 .

[0025] For river dredging, use the cutting machine on the dredger to cut and stir the soil layer at the bottom of the river to loosen the soil layer at the bottom of the river. Specifically as shown in Figure 2, in the river course to be rehabilitated, the process equipment of the present invention is installed on the dredging dredger in the river course, and the cutter 12 of the cutter 1 is placed directly below the ship, and extends to the soil layer at the bottom of the river until Mixed into the soil layer at a certain depth, driving the screw rod 11 of the reamer, linked with the cutter 12 below, reaming and stirring the river bottom soil layer, so that the soil layer becomes loose and thick mud; the suction pipe 21 extends into the thick tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com