Piston-type all-stroke engine

A piston engine and engine technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., to achieve smooth and reasonable exhaust work, solve the effects of low internal energy utilization and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

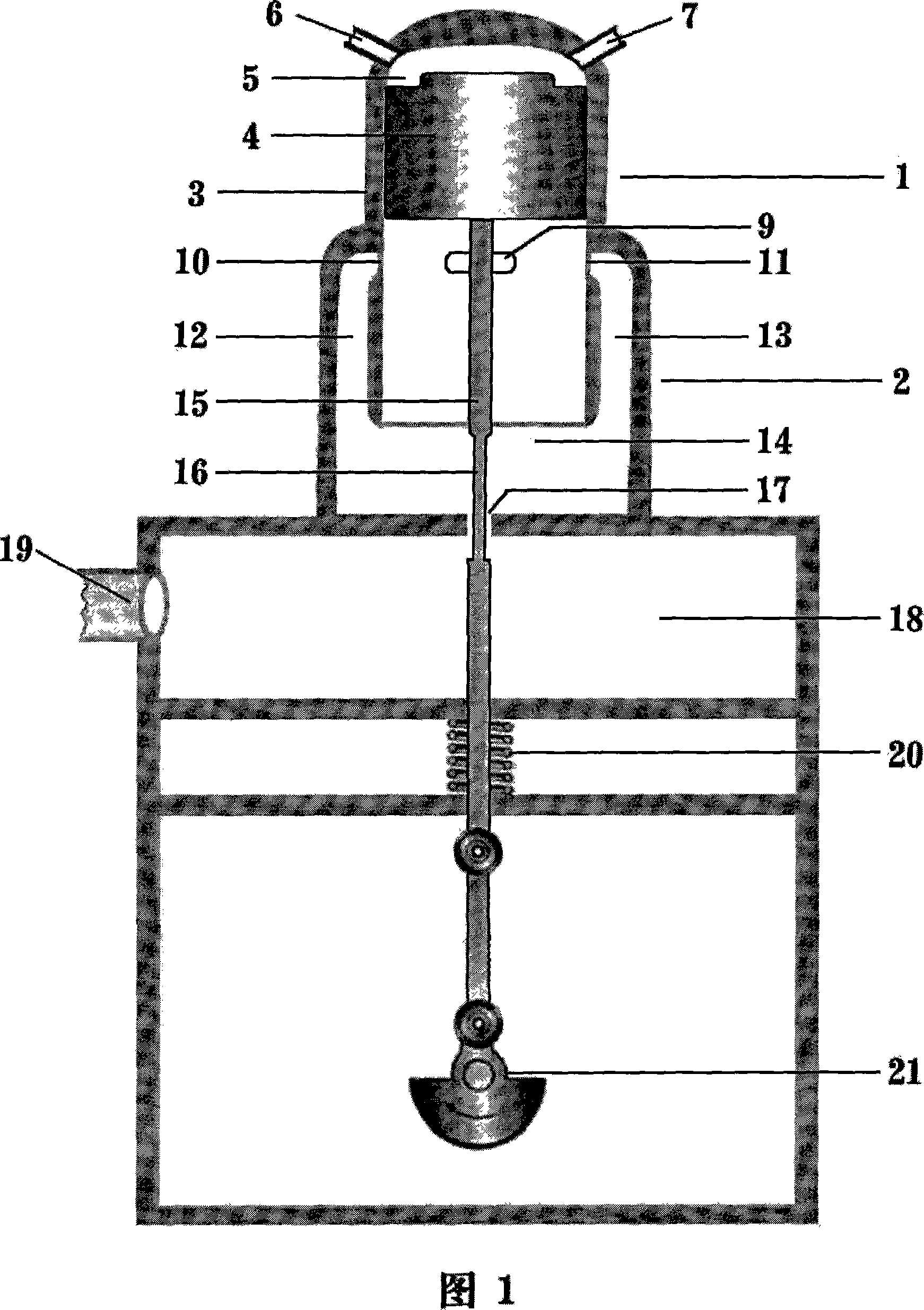

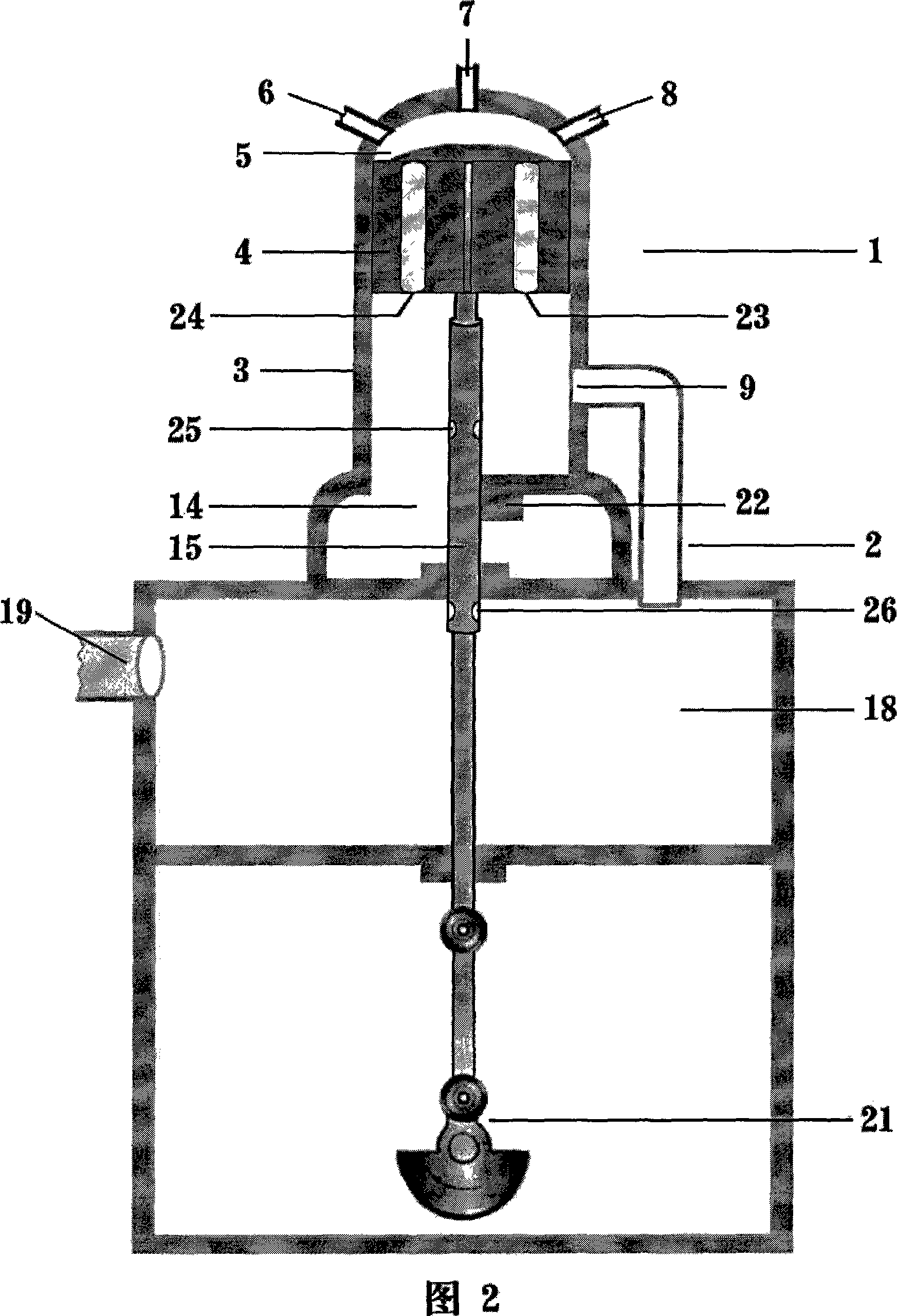

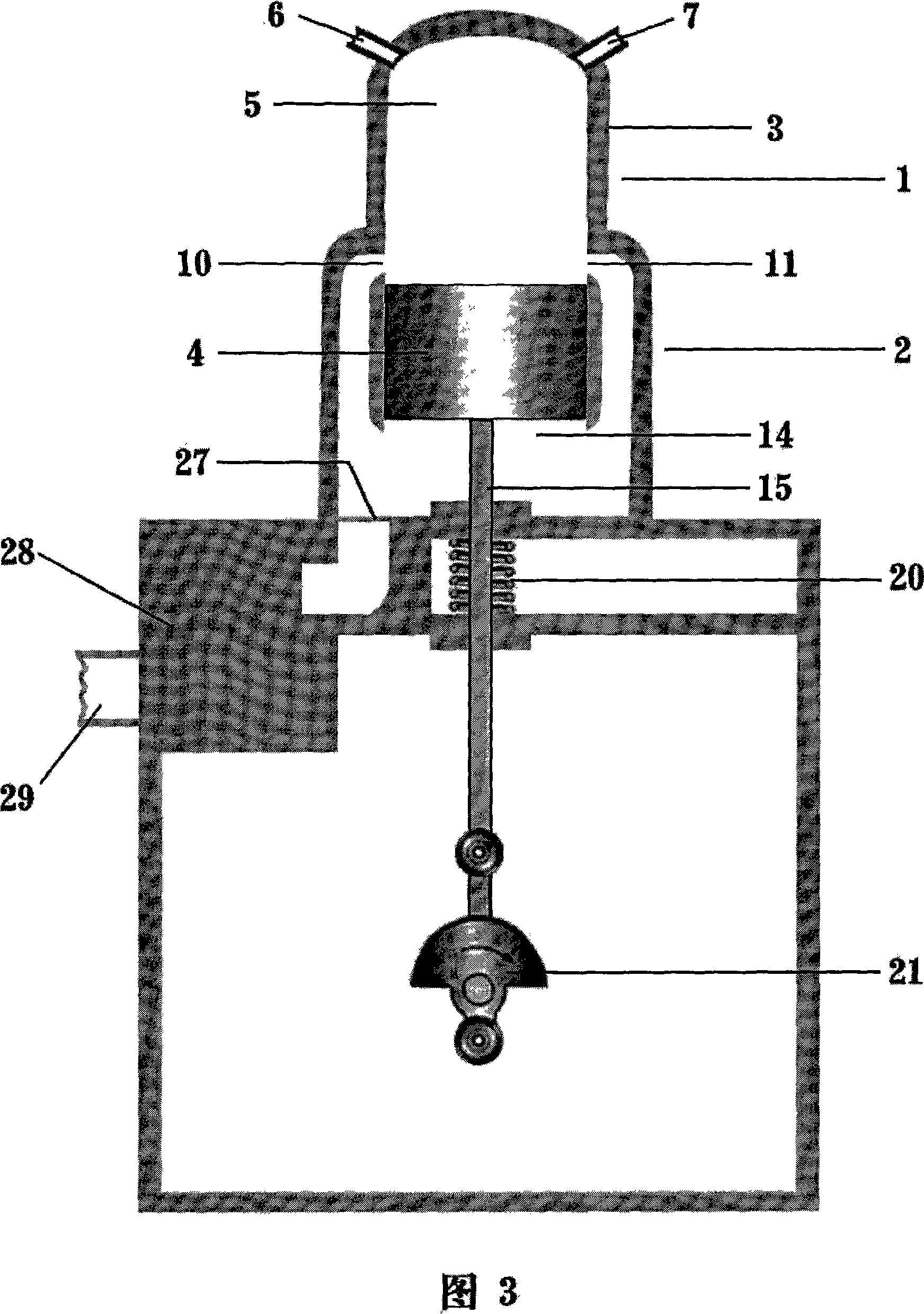

[0016] In Fig. 1, when the piston 4 in the cylinder 3 moves upward, the combustible gas is compressed, and runs to the top dead center of the piston 4, which is also the inside of the main combustion chamber 5 of the main working area 1, to compress and ignite the combustible gas, or use The igniter 6 in the main combustion chamber 5 ignites the combustible gas. At this time, in the main combustion chamber 5, under the action of the high-temperature and high-pressure gas generated instantaneously, the piston 4 is pushed down rapidly. When the piston 4 descends to close to the bottom dead center of the piston 4, the whole body of the piston 4 passes through the cylinder air outlets 10, 11 of the auxiliary work area 2, and at this moment, the cylinder air outlets 10, 11 are opened, and the high temperature in the main combustion chamber 5 The high-pressure gas enters the inside of the auxiliary combustion chamber 14 of the auxiliary work area 2 from the opened cylinder air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com