Method for rapid detecting ISO 9080 grade of PVC pipe material

An ISO9080, polyethylene pipe technology, applied in the grade field, can solve the problems that have not been practically applied, and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

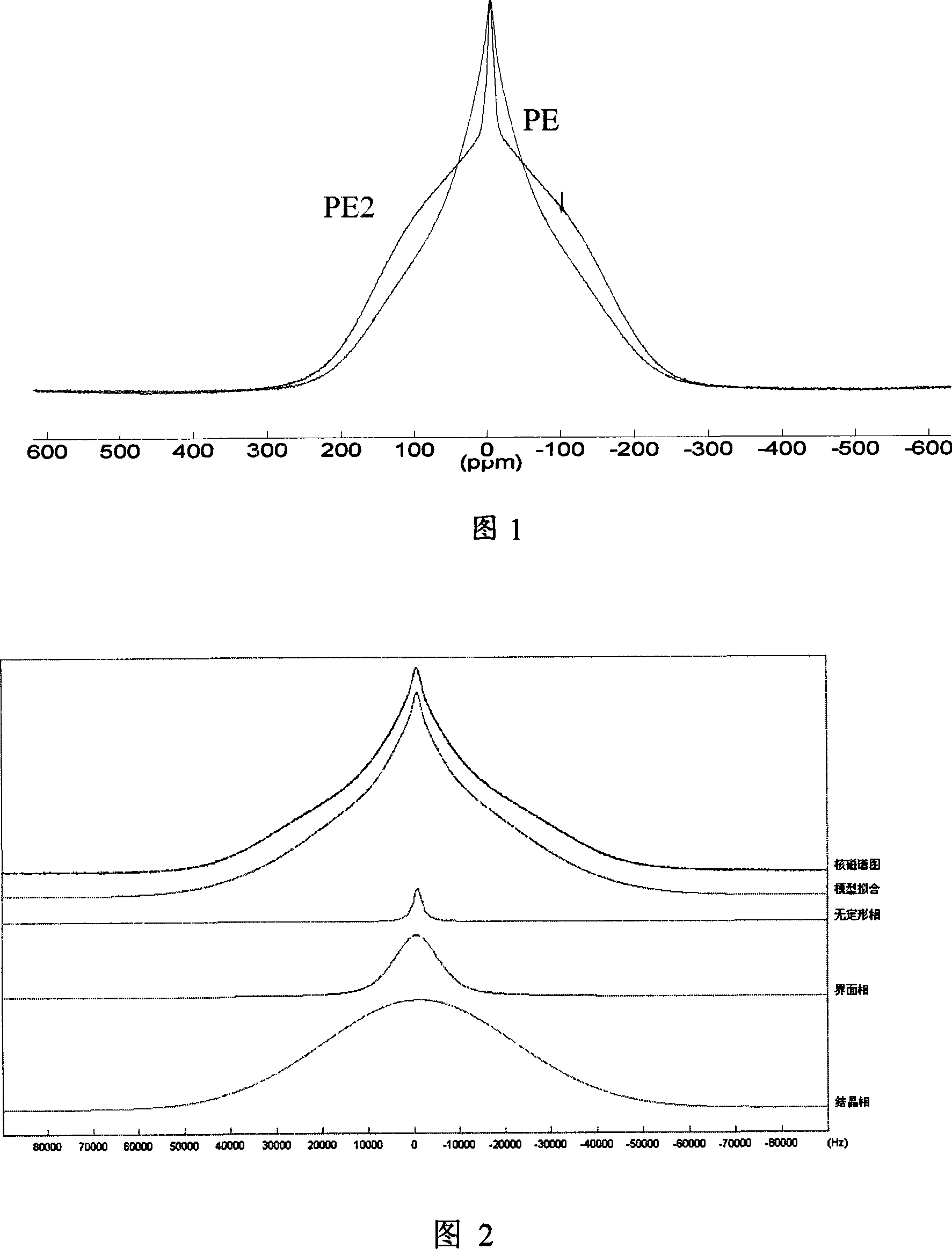

[0033] Example 1 Grade determination of different PE pipe materials by solid-state proton nuclear magnetic spectrum analysis technology

[0034] The powders of the two kinds of pipe material resins, the NMR broad-line hydrogen spectrum and the three-phase analysis of the hydrogen spectrum are shown in Figure 1 and Figure 2, respectively. The mass fractions of the three phases are given by the integral area fractions corresponding to the model curves, and the results are shown in Table 1.

[0035] Table 1 The phase content analysis results of two samples of PE1 and PE2 by solid-state NMR broad-line proton spectrum

[0036]

sample

Phase content

Crystalline phase

interface phase

PE1

PE2

0.84

0.97

0.14

0

0.02

0.03

[0037] * The result error is not more than 3%.

[0038] According to the results in Table 1, it can be judged that the pipe material corresponding to...

Embodiment 2

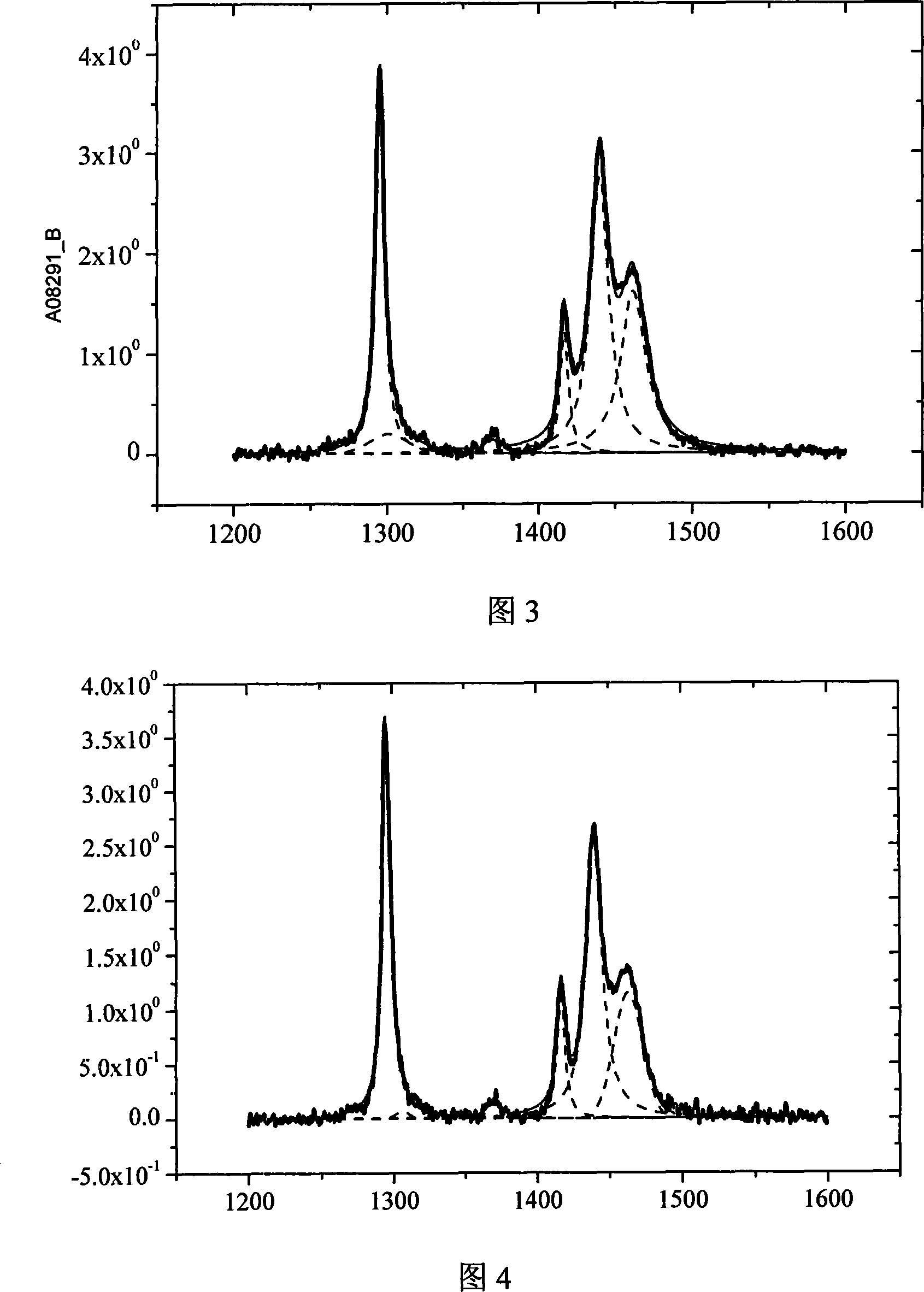

[0039] Example 2 Raman Spectroscopy Analysis Technology for Grade Judgment of Different Tube Materials

[0040] When using Raman spectroscopy to analyze the phase structure of solid polyethylene pipes, the basis is 1200cm -1 to 1600cm -1 Peak analysis of the spectrum in the C-H bond torsional vibration and bending vibration regions in the region [13]. The contents of crystalline phase, amorphous phase and interface phase are calculated by the following formulas respectively:

[0041] Crystal phase contentX C = I 1416 / [0.46(I 1295 +I 1303 )]

[0042] Amorphous phase contentX a =I1303 / (I 1295 +I 1303 )

[0043] Interface phase contentX i =1-X c -X a

[0044] Where I refers to the integral area of the spectrum peak, which is given by the computer peak division result.

[0045] The results of the analysis of the two polyethylene phase structures are shown in Table 2:

[0046] Table 2 Raman spectroscopy phase content analysis results of PE1 and PE2 samples

[00...

Embodiment 3

[0050] Example 3 The combination of wide-angle X-ray and DSC analysis technology to determine the grade of different grades of pipe materials

[0051] The wide-angle X-ray (WAXD) method can analyze the phase structure of solid polymers, and the obtained crystalline phase content includes the contribution of the interface phase, and the crystallinity given by DSC technology is approximately equivalent to the highly ordered molecular chain content of the crystalline phase. The difference in crystallinity given by the two test methods reflects the content of the interfacial phase in the solid material, from which the three-phase composition in the polyethylene pipe resin can be distinguished. The analysis and test results of the two samples of PE1 and PE2 are shown in the table 3 shows:

[0052] Table 3 Phase composition analysis of PE pipe materials by WAXD and DSC combined technology

[0053]

[0054] Comparing the results of Examples 1, 2, and 3, it can be found th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com