Multi-phase bubbling reactor

A multiphase reactor and bubbling technology, applied in chemical methods, chemical instruments and methods, and chemical/physical processes for reacting liquid and gaseous media, can solve the problem of interphase mass transfer and the reduction of reactant conversion rates, affecting Interphase contact effect, small specific surface area, etc., to achieve the effect of fast dissolution, simple structure, and high mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

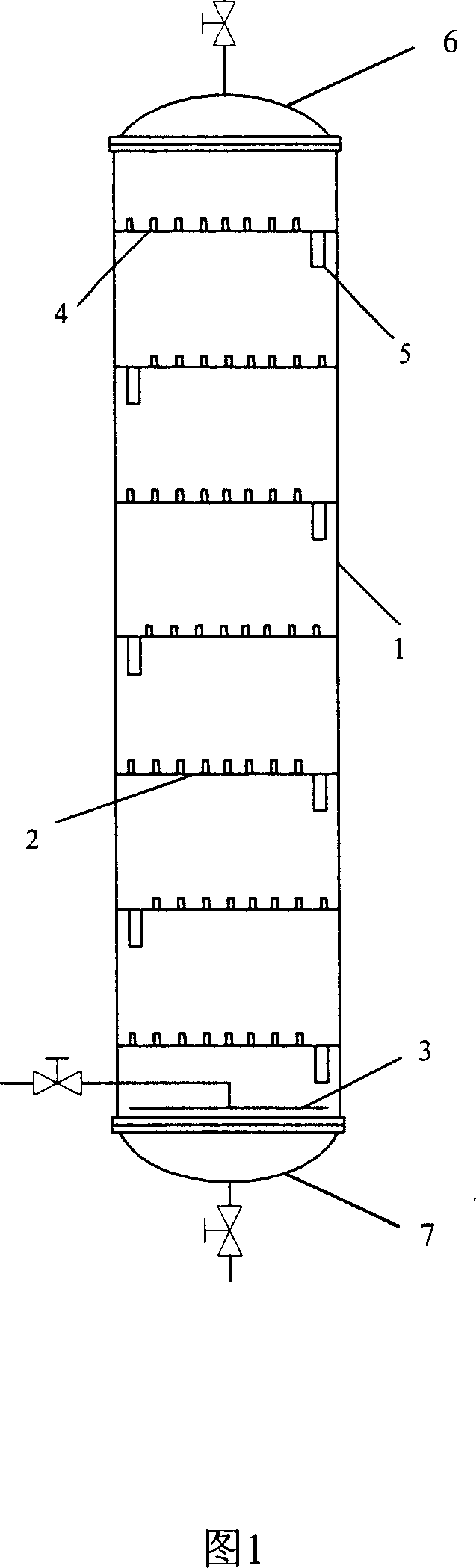

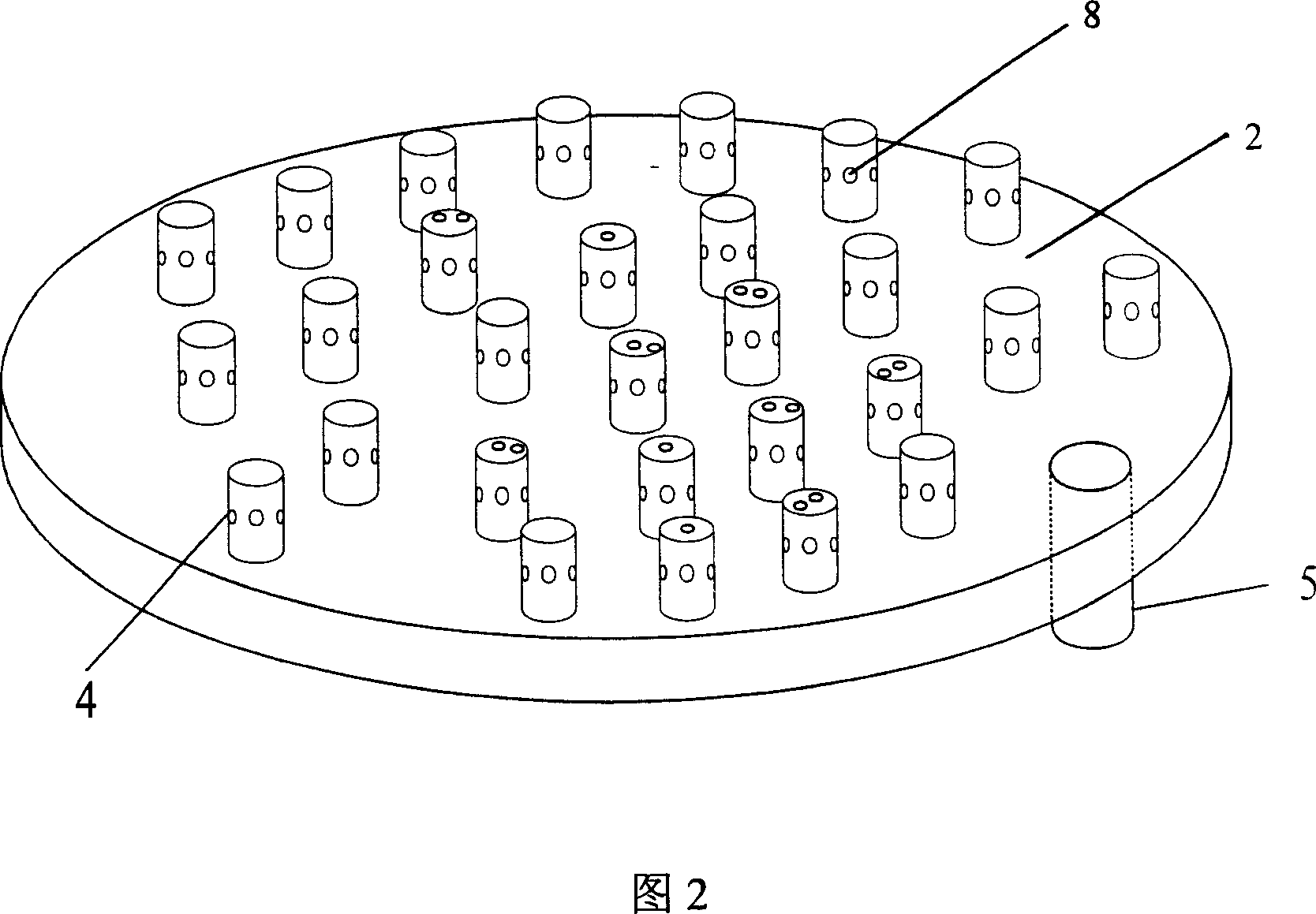

[0016] For the gas-liquid system, atmospheric pressure air is used as the gas medium, and the liquid phase medium is water. Experimental reactors were bubbling bed reactor (Comparative Example 1) and bubbling heterogeneous reactor (Example 1). Among them, the inner diameter of the outer cylinder of the bubbling bed reactor is 0.30m, the total height of the reactor is 3.0m, and the bottom of the reactor is spherical and equipped with a gas distributor. The internal diameter of the bubbling heterogeneous reactor (column body 1) is 0.30 m, the total height of the reactor is 3.0 m, the bottom 7 of the reactor tower is spherical, and a gas distributor 3 is installed near the bottom of the tower. The bubbling multiphase reactor is equipped with six trays 2 with a distance of 0.3m between the trays. On the trays, 50 gas risers 4 are arranged upwards. The gas risers are arranged in an equilateral triangle. The height of the gas risers is 10mm and the inner diameter is 8mm. Two air ho...

Embodiment 2

[0020] For the gas-liquid-solid three-phase system, the atmospheric pressure air is used as the gas medium, and the coal-water slurry with a concentration of 20% is the liquid-solid phase. The particle size of coal is less than 0.15mm, and the reactor used in the experiment is a bubbling multiphase reactor. The inner diameter of the tower body 1 of the bubbling multiphase reactor is 0.30m, the total height of the reactor is 3.0m, and the bottom 7 of the reactor tower is spherical. A gas distributor 3 is installed near the bottom of the tower. The reactor is equipped with six trays 2 with a spacing of 3.0m. On the trays, 50 air risers 4 are arranged upwards. The long air pipes are arranged in concentric circles. The height of the air risers is 10mm and the inner diameter is 8mm. Four ventilation holes 8 with a diameter of 1.5 mm are regularly opened, and two downcomers 5 are arranged symmetrically downward on both sides of the tray.

[0021] Under the condition of the ventilat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com