Method for extracting rectifying and separating benzene

A technology of extractive distillation and extractive distillation column, which is applied in the field of extractive distillation and separation of benzene, can solve the problems of operation fluctuation, unqualified color number of pickling, and increase of production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

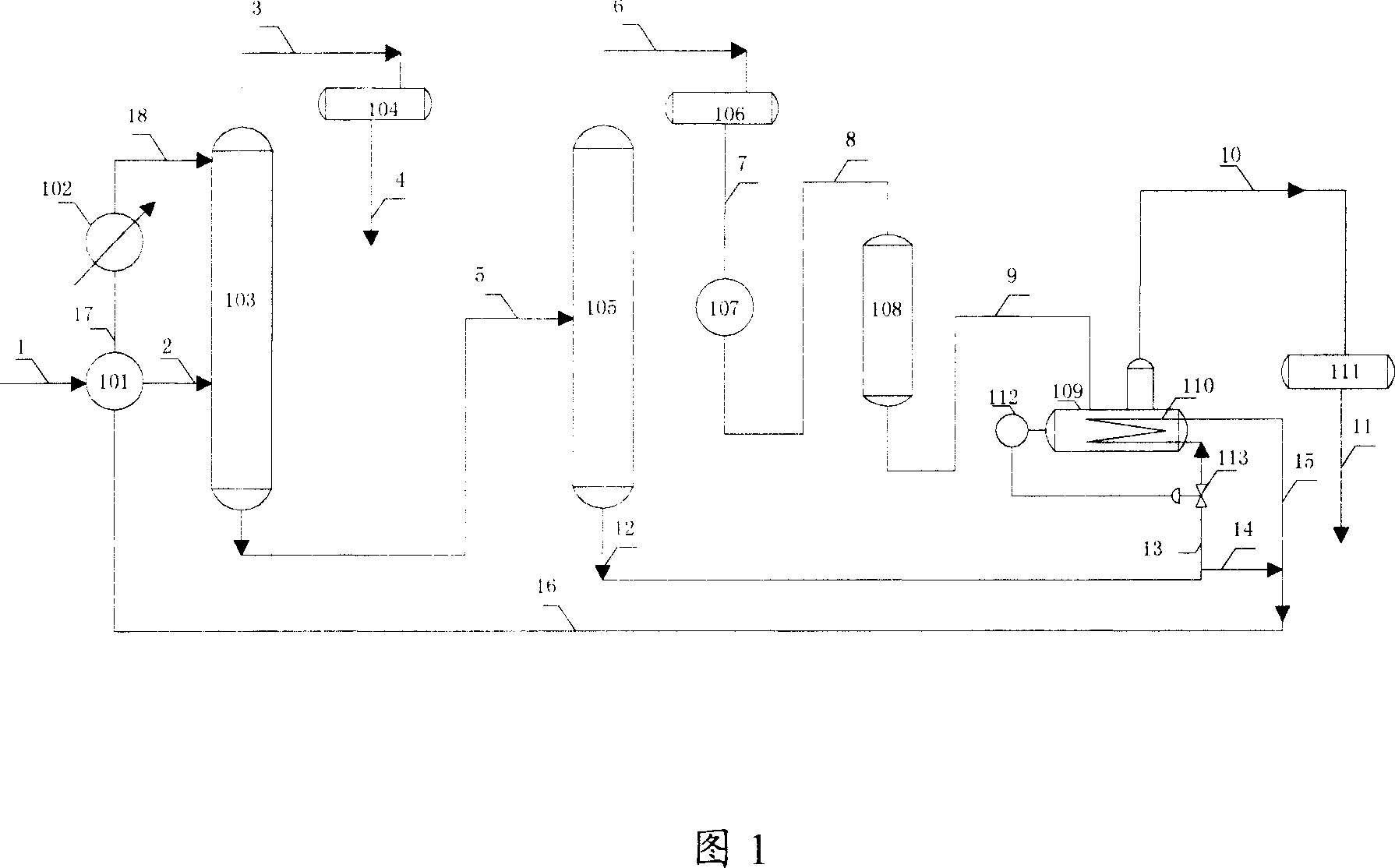

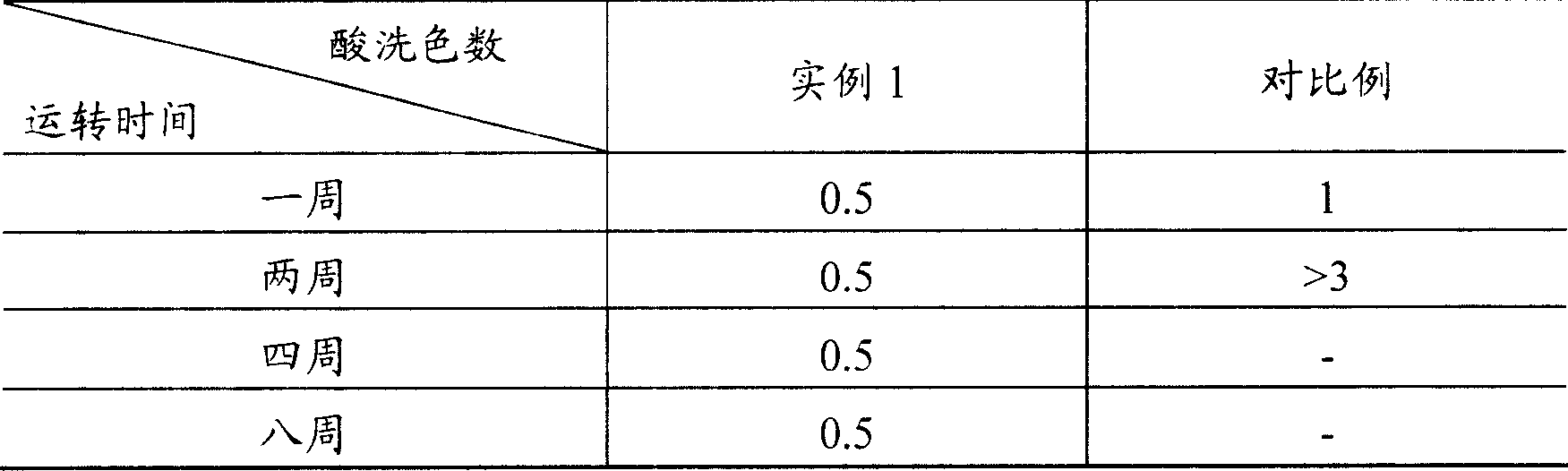

[0025] According to the flow chart in Figure 1, to reform gasoline C 6The distillate is used as the raw material, and pure benzene is separated by extractive distillation, and sulfolane is used as the extraction solvent. The composition and flow rate of raw materials in the extractive distillation process are shown in Table 1, the main operating conditions are shown in Table 2, the circulation flow rate and heat exchange temperature of the solvent are shown in Table 3, and the separation results of extractive distillation are shown in Table 4. The pickling color number of the product is shown in Table 5, and the pickling color number is determined by the GB / T2012 method.

example 2~3

[0031] According to the flow chart of Fig. 1, the benzene cut that the solvent recovery tower top obtains is taken as raw material, and the influence of the number of theoretical plates on the top of the flash tank on the extraction and separation results is investigated. The composition of the benzene cut is shown in Table 6, the composition of the clay tower and the flash tank The operating conditions are shown in Table 7, and the separation results are shown in Table 8.

[0032] From the data in Table 8, it can be seen that when the number of theoretical plates on the top of the flash tank is 0 or 5, the benzene product with qualified pickling color number can be obtained, but the yield of benzene is low when the number of theoretical plates is 0.

[0033] project

[0034] project

[0035] project

[0036] project

[0037] Total heat consumption refers to the sum of extractive distillation and benzene refining heat.

[0038] table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com