Controllable immersing polymer colloidal photon crystal film at normal-temperature, its production and use

A technology of colloidal photonic crystals and polymer latex, which is applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc., to achieve the effect of simple equipment and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of polymer colloidal photonic crystal film with controllable wettability

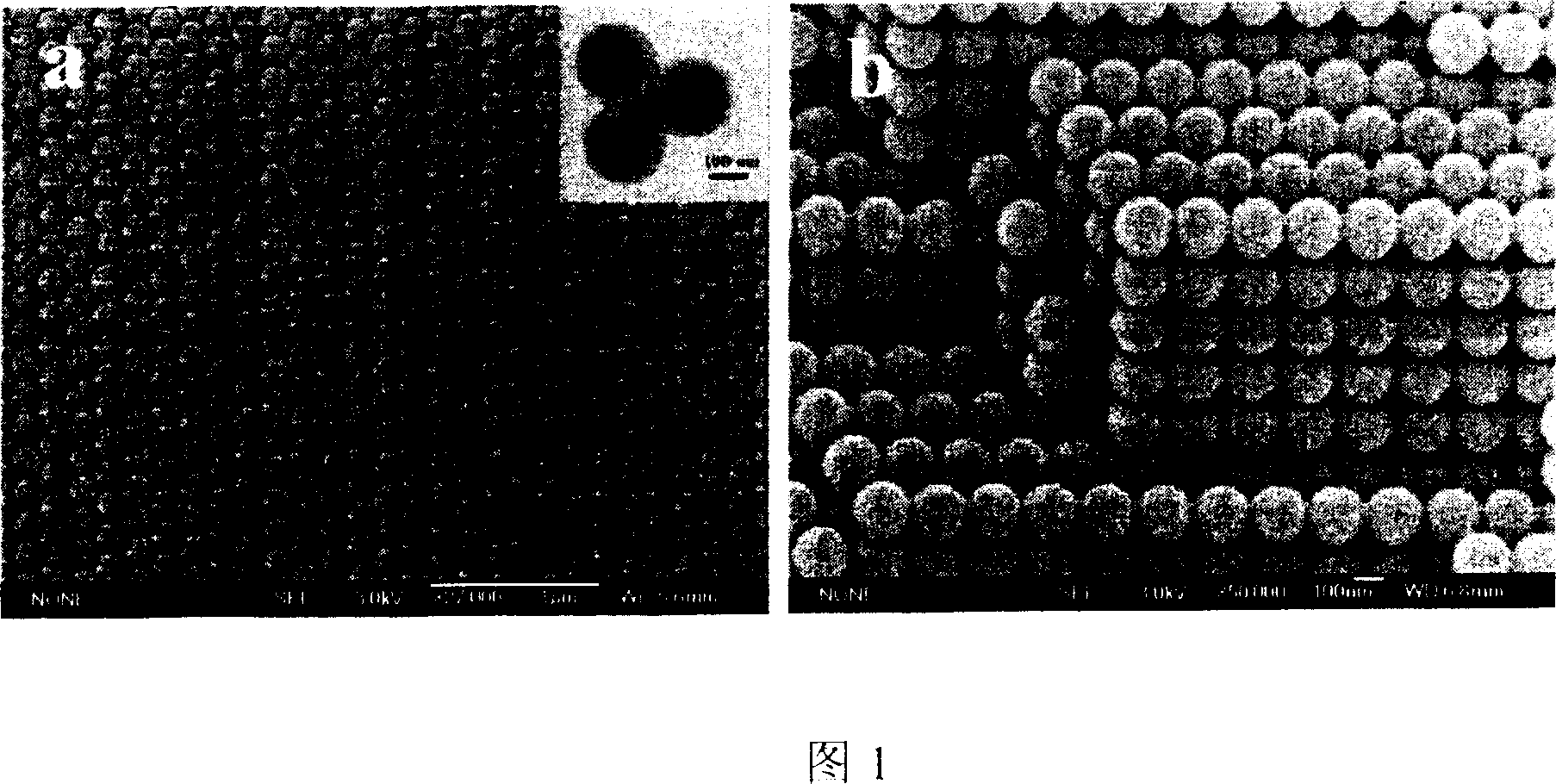

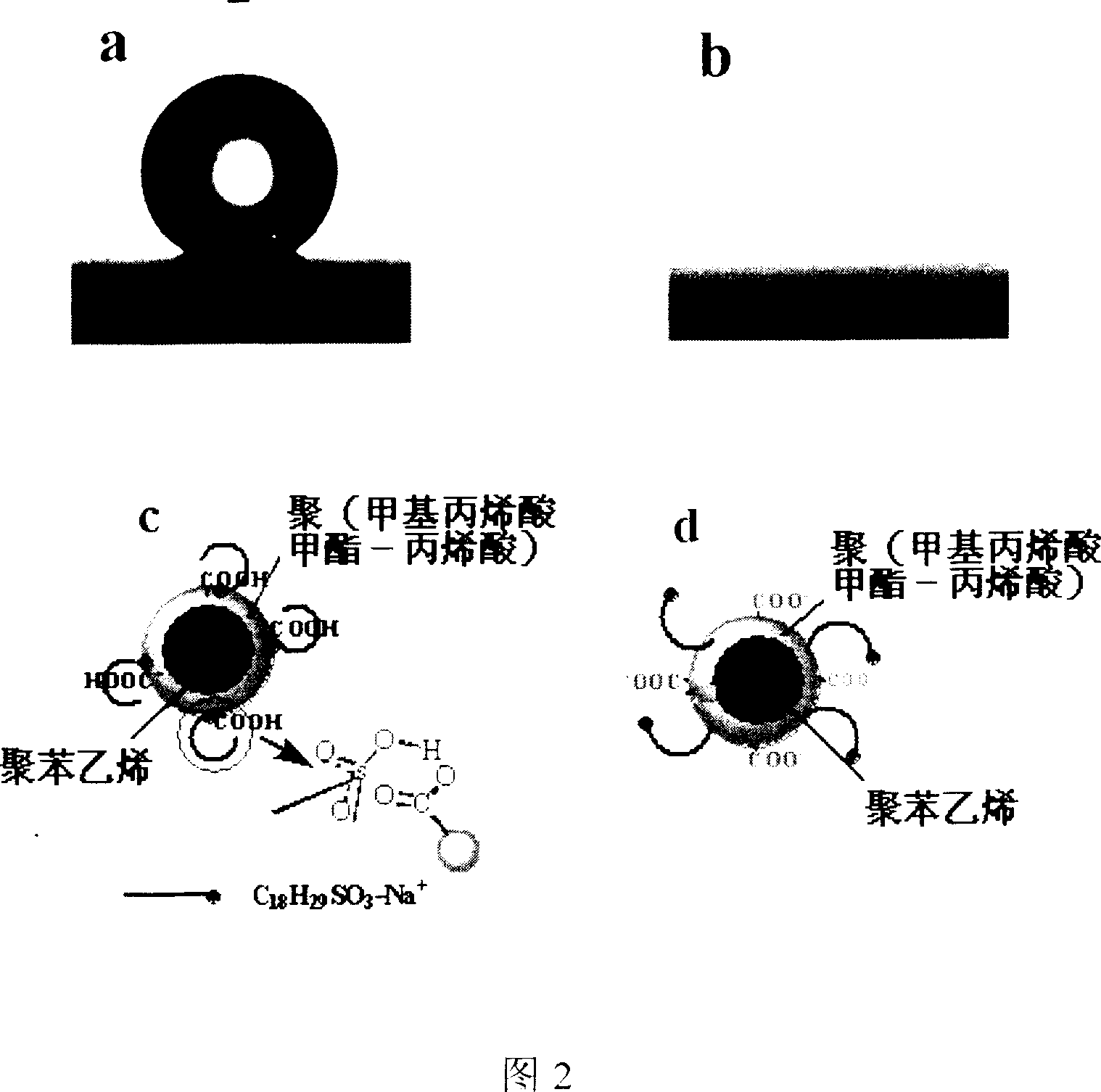

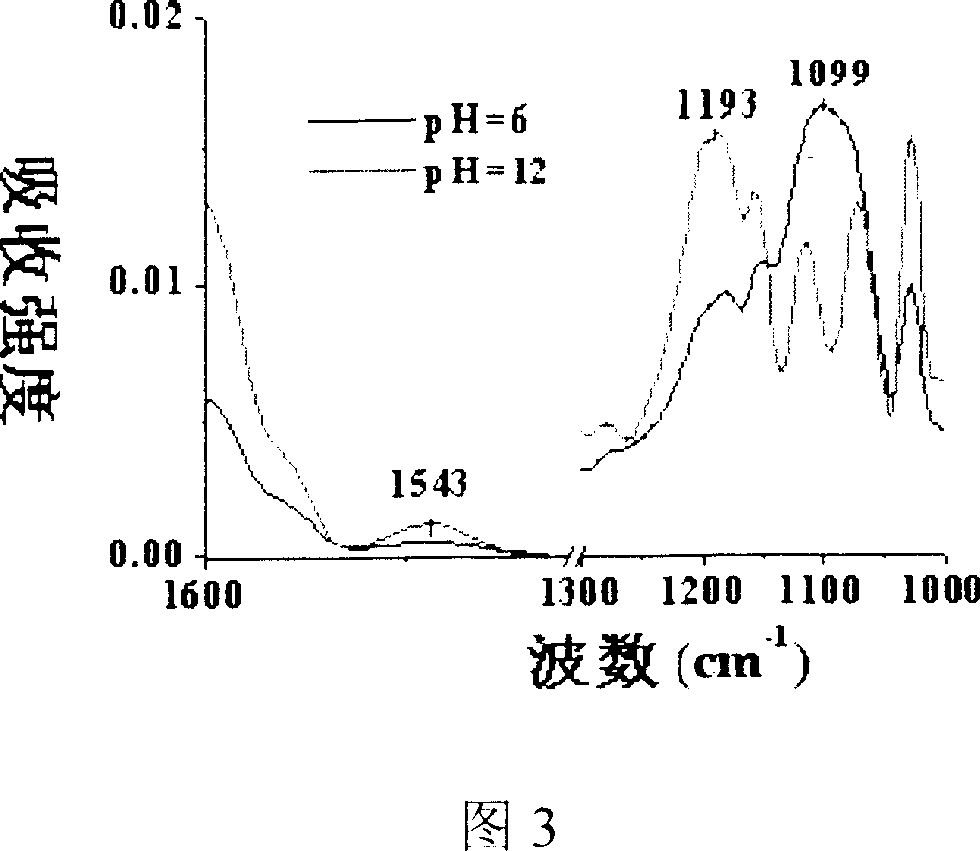

[0045] At room temperature at 25°C, the monodisperse polymer poly(styrene-methyl methacrylate-acrylic acid) latex particles (particle diameter is 160nm, with obvious Core-shell structure, see the inset in Figure 1a), adding ammonia water to adjust the pH of the latex suspension from 6 to 14 to adjust the hydrophilic group SO 3 - The method of bonding with the carboxyl group of the hydrophilic group on the surface of the latex particles, and then uniformly cover the obtained monodisperse polymer latex particle emulsion on the flat substrate, wherein the concentration of the monodisperse polymer latex particle emulsion is 5 to 30wt %. Evenly cover the obtained latex suspension on the clean glass, silicon wafer or stainless steel plate substrate, put the substrate of the coating film at room temperature, and after the water of the dispersion liquid evaporates to dryness, it w...

Embodiment 2

[0050] Embodiment 2: (waterproof coating applied to ultraviolet region)

[0051] According to the method of Example 1, the monodisperse polymer poly(styrene-methyl methacrylate-acrylic acid) latex particles were assembled at a temperature of 25°C to obtain a waterproof coating in the ultraviolet region. Depending on the particle size of the latex particles used, a waterproof UV coating can be obtained.

Embodiment 3

[0052] Embodiment 3: (material for waterproofing and preventing ultraviolet rays)

[0053] At room temperature, the polymer colloidal photonic crystal film with room temperature controllable infiltration prepared by the monodisperse polymer poly(styrene-methyl methacrylate-acrylic acid) latex particles with a concentration of 5wt% according to the method in Example 1, when The particle diameters of the monodisperse polymer latex particles are respectively 100, 115, 120, 125, 130, 150 or 160 nanometers, and the corresponding photonic bandgap positions of the prepared colloidal photonic crystal films are respectively 253, 281, 300, 319, 327, 345, 380nm. The obtained coating can be directly used to prevent ultraviolet rays, and according to the different substrates used, the used coating can be used on automobile film, glass and other facilities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com