Photon crystal membrane of polymer colloid with controllable wet ability, prepartion method and application

A technology of colloidal photonic crystals and polymer latex, applied in cosmetic preparations, dressing preparations, cosmetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 Preparation of polymer colloidal photonic crystal film with controllable wettability

[0063] At room temperature, the monodisperse latex particles (particle size of 170 nm, with obvious particle diameter of 170 nm) of the terpolymer poly(styrene-methyl methacrylate-acrylic acid) prepared by the method described in the aforementioned patent application were prepared at a concentration of 5 wt %. Core-shell structure, the core layer is hard polystyrene, the shell layer is composed of soft and elastic polymethyl methacrylate and polyacrylic acid, and the shell layer thickness of the monodisperse polymer latex particles is 20-25 nm. figure 1 ) emulsion, evenly cover the clean glass, silicon wafer or stainless steel substrate, put the substrate of the coating film at a certain temperature (35 ~ 90 ℃), and after the water in the dispersion is evaporated and dried, it will form a periodic The ordered three-dimensional photonic crystal film is composed of monodispers...

Embodiment 2

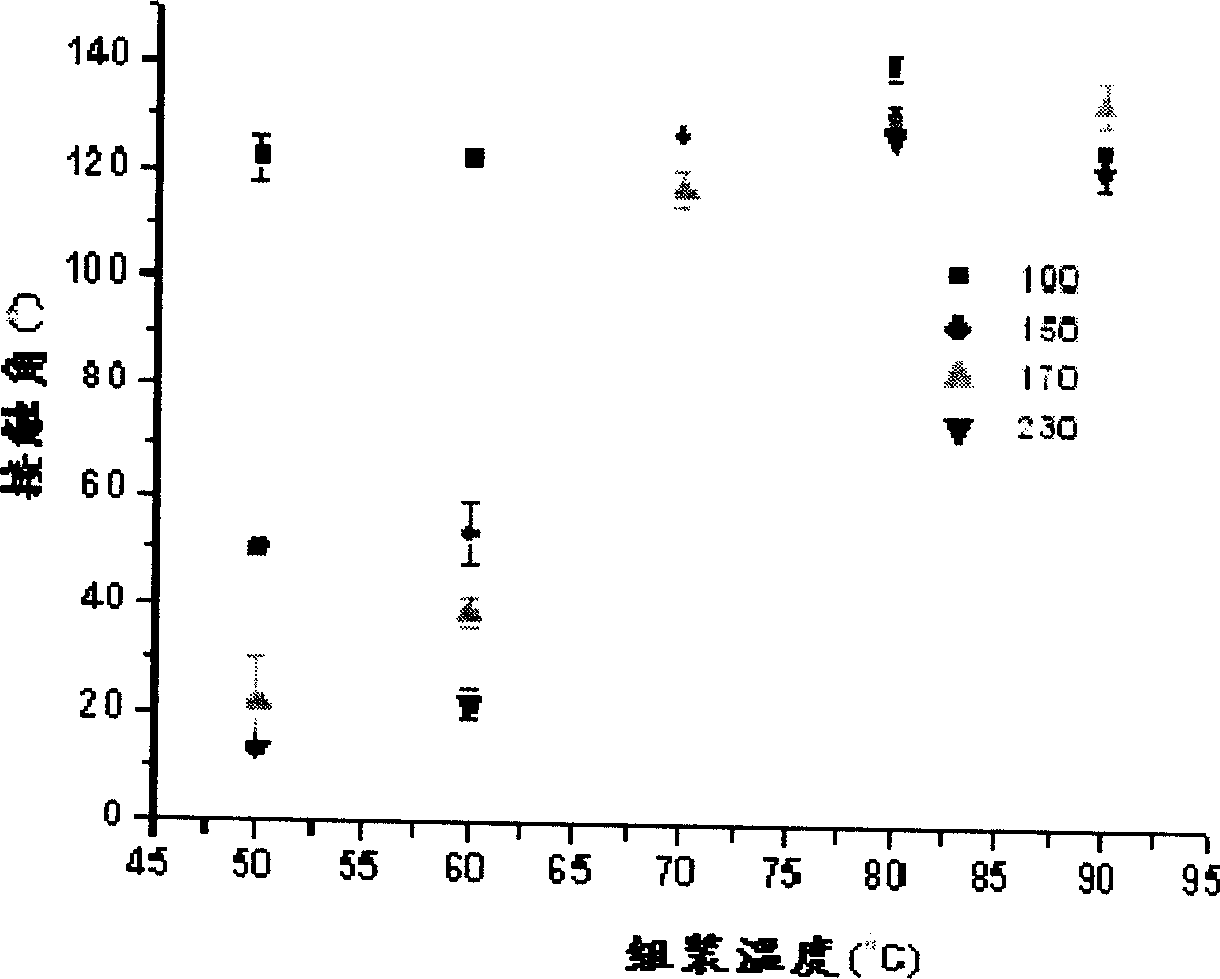

[0065] Depending on the evaporation temperature of the dispersion water, the wettability results of the prepared films are as follows figure 2 shown. At room temperature, the monodispersed latex particle emulsion of the terpolymer poly(styrene-methyl methacrylate-acrylic acid) prepared by the method described in the aforementioned patent application with a concentration of 10 wt% was uniformly covered on a clean glass base. On the material, the particle sizes of the polymer latex particles are 100nm, 150nm, 170nm, and 230nm respectively (the shell thickness of the monodisperse polymer latex particles is 20-25nm), and the water temperature is 50°C, 60°C, 70°C, 80°C. ℃, after volatilizing to dryness at 90℃, the change of the contact angle of the film assembled on the glass substrate is given by figure 2 It can be seen that with the increase of assembly temperature, the contact angle of the membrane gradually increases, and the wettability of membranes with different particle ...

Embodiment 3

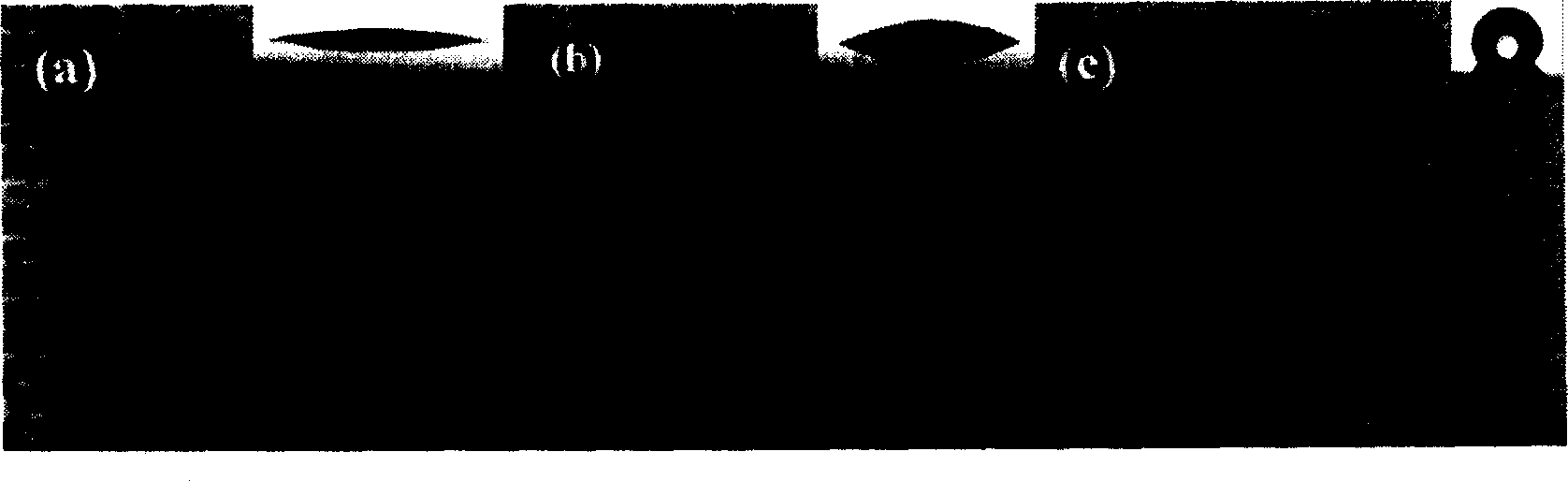

[0068] Example 3: Waterproof coating applied to UV or visible region

[0069] According to the method of Example 1, the monodisperse latex particles (particle size of the terpolymer poly(styrene-methyl methacrylate-acrylic acid) prepared by the method described in the aforementioned patent application with a concentration of 15 wt% 100~300nm, with obvious core-shell structure, the core layer is hard polystyrene, the shell layer is composed of soft and elastic polymethyl methacrylate and polyacrylic acid, the shell layer of monodisperse polymer latex particles 20-25nm thick) emulsion, which is evenly covered on the clean stainless steel substrate, and the substrate of the coating film is placed at a certain temperature (70°C or above), and after the water in the dispersion is evaporated and dried, it will form a periodic An ordered three-dimensional photonic crystal film that can be used as a waterproof coating in the ultraviolet or visible region. The waterproof performance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com