Method for producing nano-magnetic FeO particle by iron extracted and utilized in tin tails

A nano-magnetic, tailings technology, applied in ferrous oxide, process efficiency improvement, ferric oxide/ferric hydroxide, etc., to achieve the effect of high extraction rate, simple extraction process and fine particle size

Inactive Publication Date: 2007-09-05

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the use of iron extracted from tailings to prepare nano-magnetic materials is still blank.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

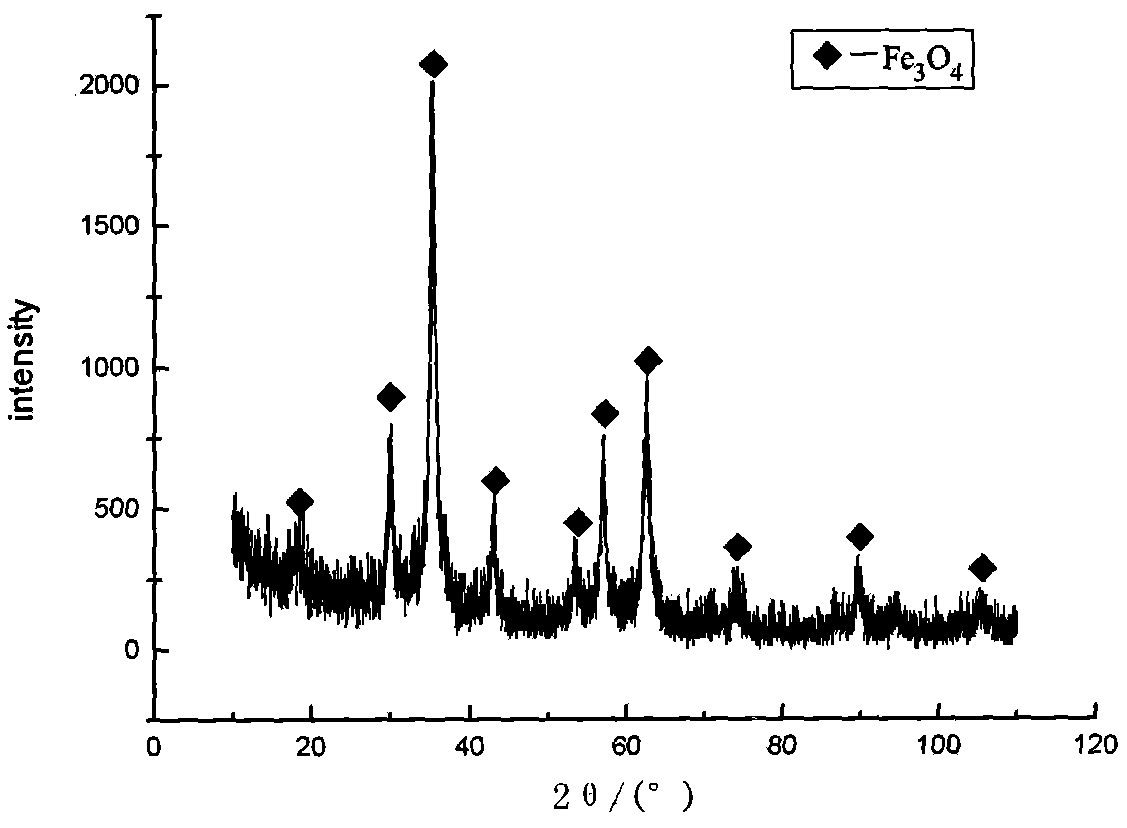

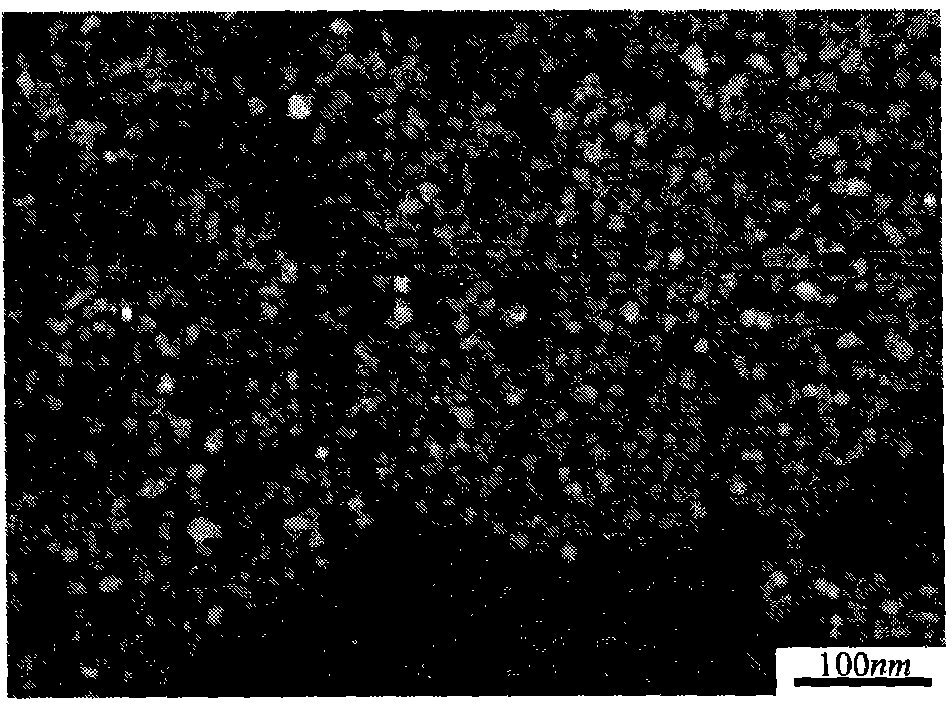

Production of magnetic nano-Fe3O4 by iron in tin tails is carried out by extracting while separating out iron element by wetting metallurgical technology, reduction-chemical co-depositing to obtain magnetic nano-Fe3O4, extracting while controlling hydrolytic temperature, ageing, secondary depositing to obtain high-purity ironic hydroxide deposits and surface coating by surface activator to obtain Fe3O4 grain with grain size<10nm. It is efficient and can obtain fine and uniform grain size. It can be used for magnetization, catalytic and biological industries.

Description

technical field The invention belongs to the technical field of comprehensive utilization of mine tailings and preparation of nano-magnetic materials, and in particular provides a method for extracting iron elements rich in mine tailings and preparing nano-magnetic Fe 3 o 4 particle method. Prepared Fe 3 o 4 The particle size is uniform and fine and has superparamagnetism. Background technique Mineral resources are a kind of non-renewable resources. With the increasing demand for mineral resources in social development and the continuous development of mineral resources, mineral resources are increasingly depleted. At the same time, the harm to the environment caused by the development of mineral resources has made people realize the importance of resource protection, environmental protection and utilization for sustainable social and economic development. A large number of facts show that mine tailings, as a secondary resource, must be comprehensively utilized both in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B3/10C22B1/14C22B3/22C22B3/44C01G49/08

CPCY02P10/20

Inventor 徐利华张菡

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com