Circulation utilization method for light oil cracking tail gas

A light oil cracking and tail gas technology, applied in chemical instruments and methods, gas mixture processing, petroleum industry, etc., can solve problems such as environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

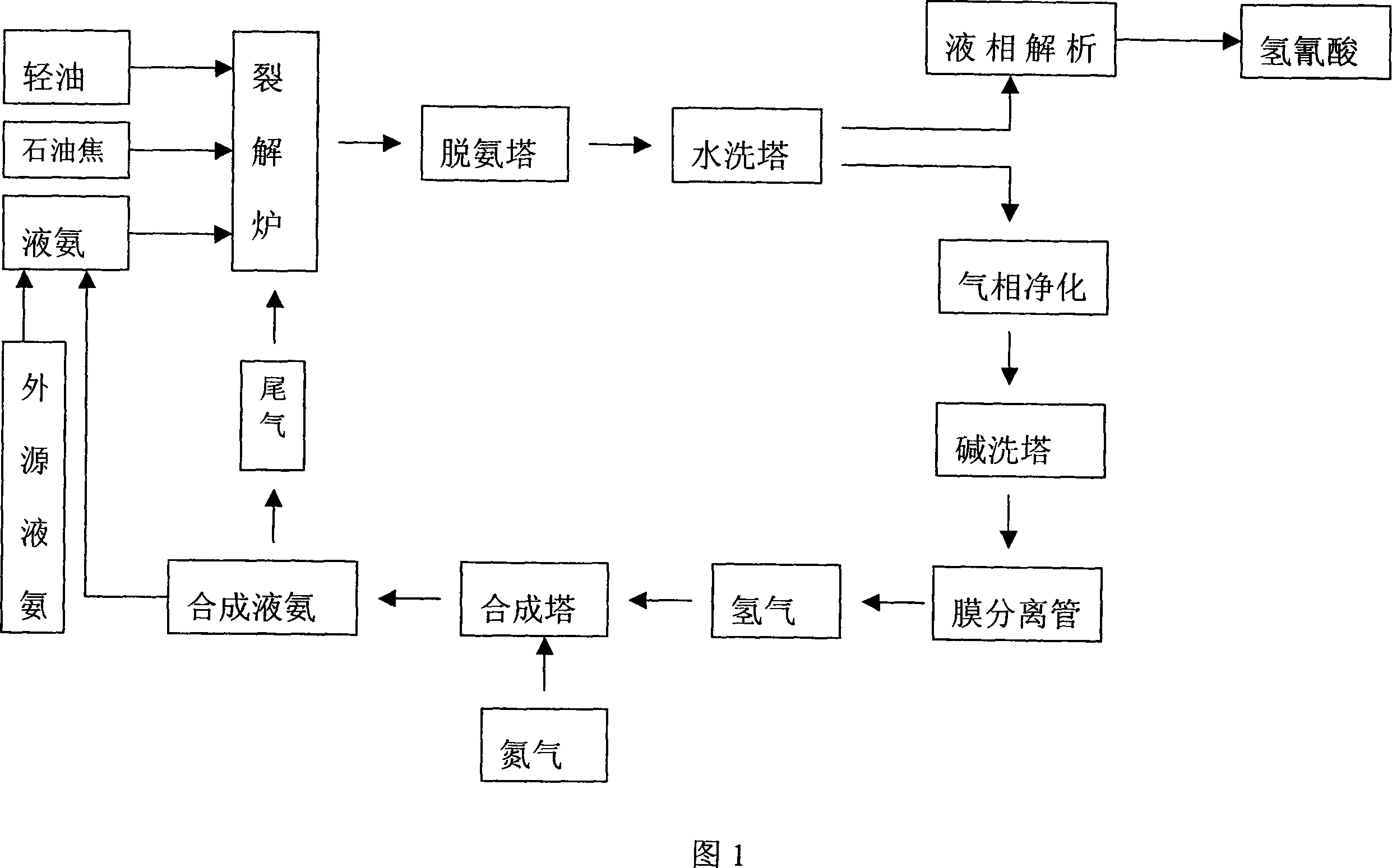

[0022] Take the production enterprise of 40,000 tons of prussic acid per year as an example, the process flow of the inventive method is as shown in Figure 1, and the process steps are:

[0023] a. Use C 5 h 12 13,000 tons of light oil, 40,000 tons of liquid ammonia, 13,000 tons of petroleum coke, the liquid ammonia is gasified with C 5 h 12 The light oil is mixed in the Venturi tube, and then heated to 250°C to 280°C by the pre-heater and enters the bottom of the cracking furnace, and the screw feeder feeds petroleum coke, and the raw material gas undergoes cracking reaction at a high temperature of 1450°C and a slight negative pressure , generating a cracked product mainly composed of hydrogen cyanide and hydrogen and containing a small amount of nitrogen and carbon powder;

[0024] b After the lysate is cooled, remove the carbon ash, enter the deammonization tower, remove unreacted ammonia with dilute sulfuric acid, then enter the water washing tower to wash off the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com