Probe built-in type hydrogen gas leakage detector

A leak detector and built-in technology, applied in the field of hydrogen leak detectors with built-in probes, can solve problems such as the inability to intuitively indicate the position and direction of the leak point, the limitation of the application range of the external hydrogen-sensing probe, and the difficulty in distinguishing and determining the direction of movement, etc. problems, to achieve the effect of improving reliability and adaptability, improving reliability and intuitiveness, and improving leak detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

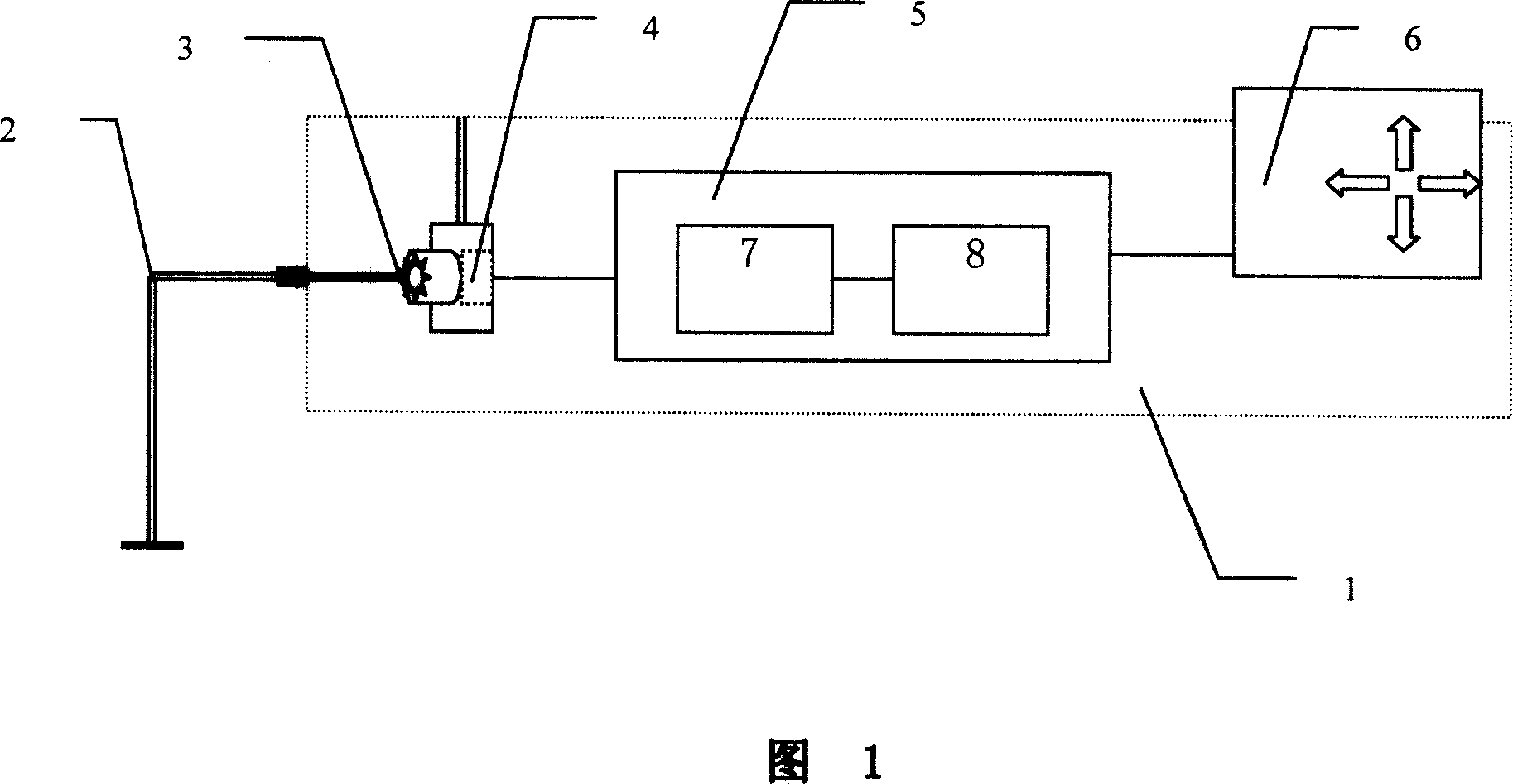

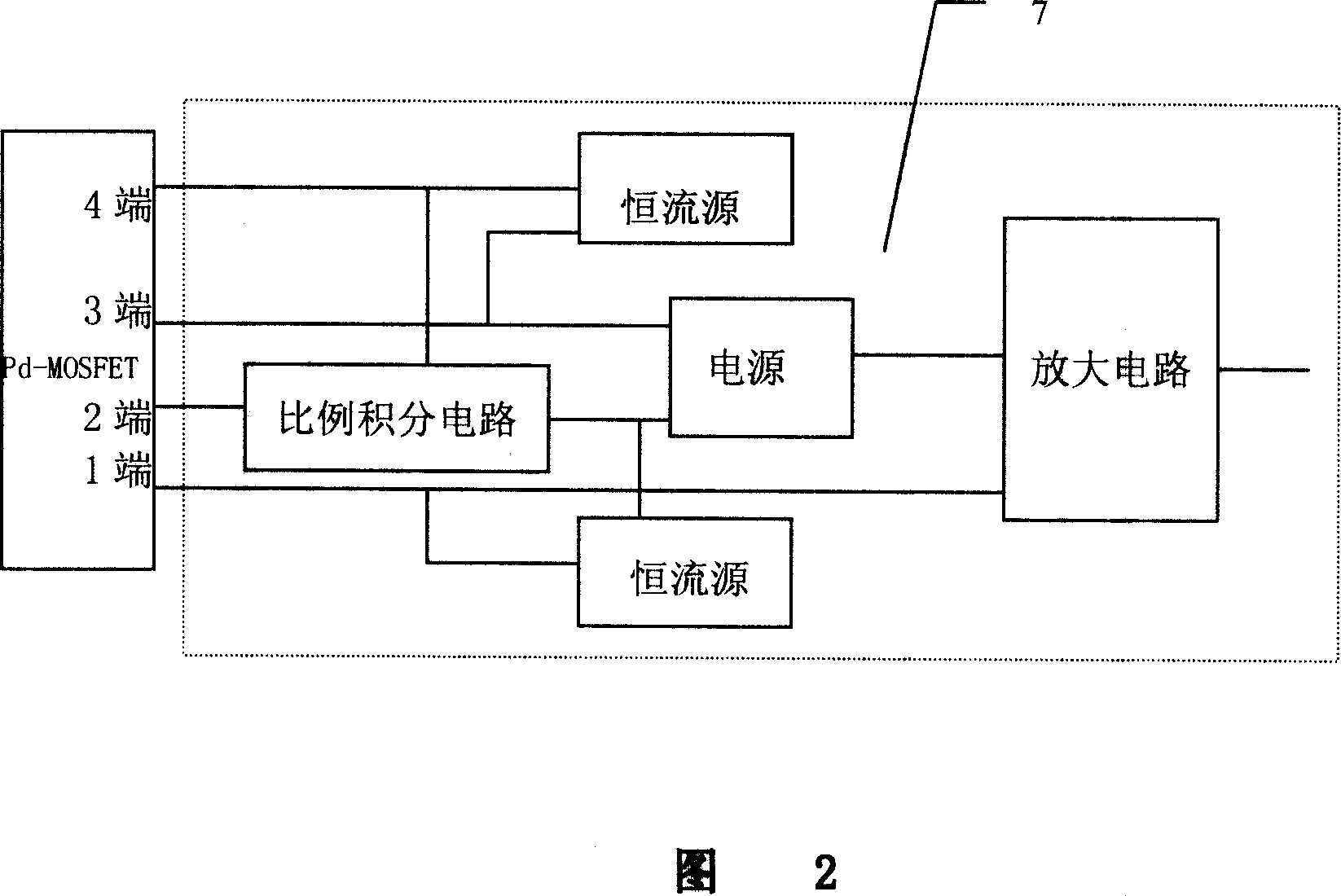

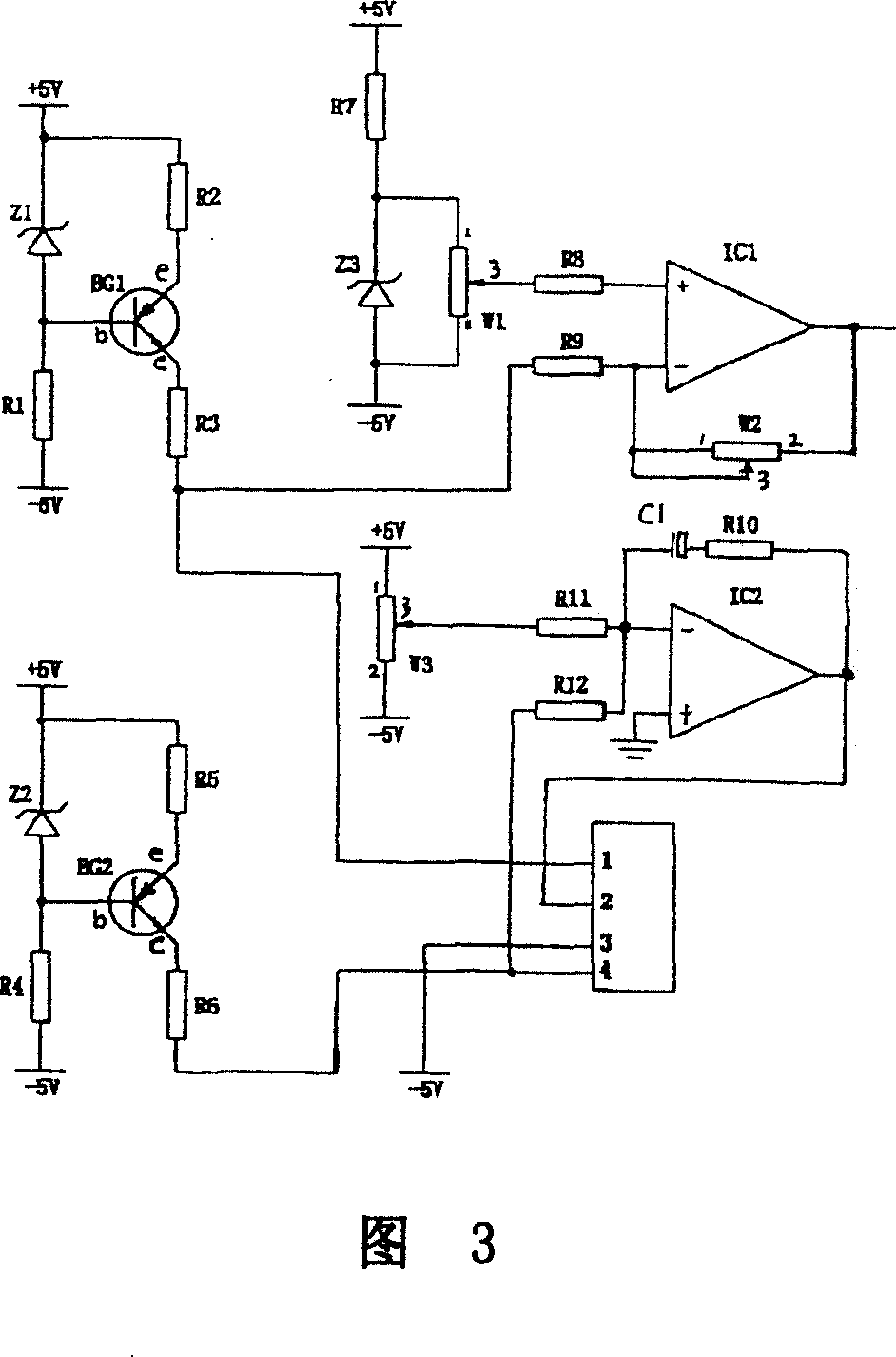

[0027] In Figure 1, the probe built-in hydrogen leak detector 1 of the present invention includes an external suction pipe 2, a micro suction pump 3, a hydrogen sensitive probe 4, a signal processing circuit 5 and an indicating circuit 6, wherein the micro suction pump 3 and hydrogen The sensitive probe 4 is built in the hydrogen leak detector, the inlet of the micro getter pump 3 is closed and connected to the end of the external suction pipe 2, and the hydrogen sensitive probe 4 of the hydrogen detection part is placed in the outlet pipe of the micro getter pump 3. The inhaled sample gas is discharged from the hydrogen leak detector body along the airflow path in a pressurized state after passing through the micro suction pump 3 and the hydrogen sensitive probe 4. The hydrogen sensitive probe 4 uses a hydrogen sensitive semiconductor sensor, and its signal output terminal is connected with the signal processing circuit 5 The input terminal of the signal processing circuit 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com