High-pressure liquid air tube type quick mixing reactor

A technology of mixing reactors and high pressure liquids, applied in chemical/physical/physical chemical nozzle reactors, fluid mixers, mixers, etc. The effect of compact form, low cost, great flexibility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

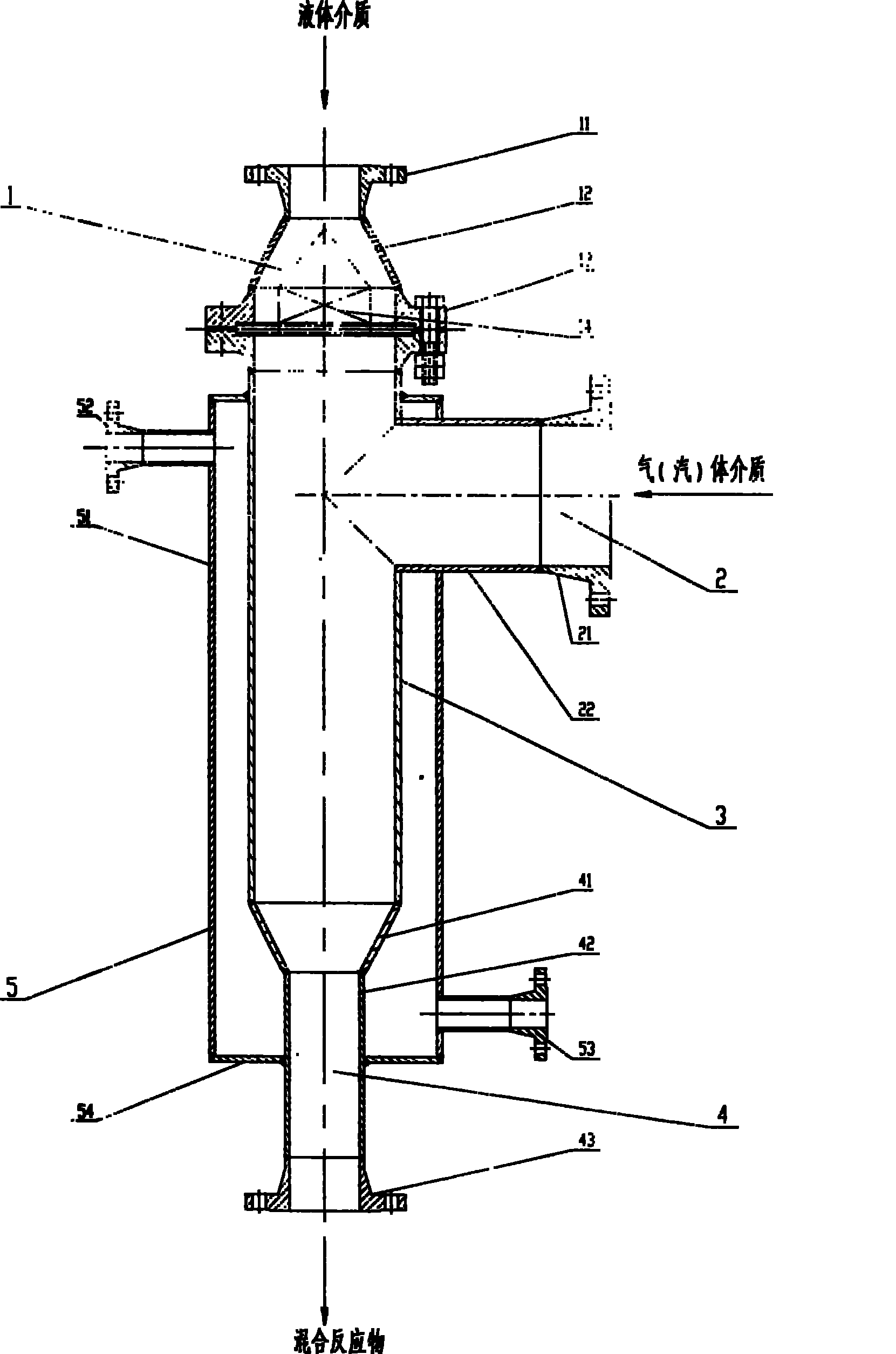

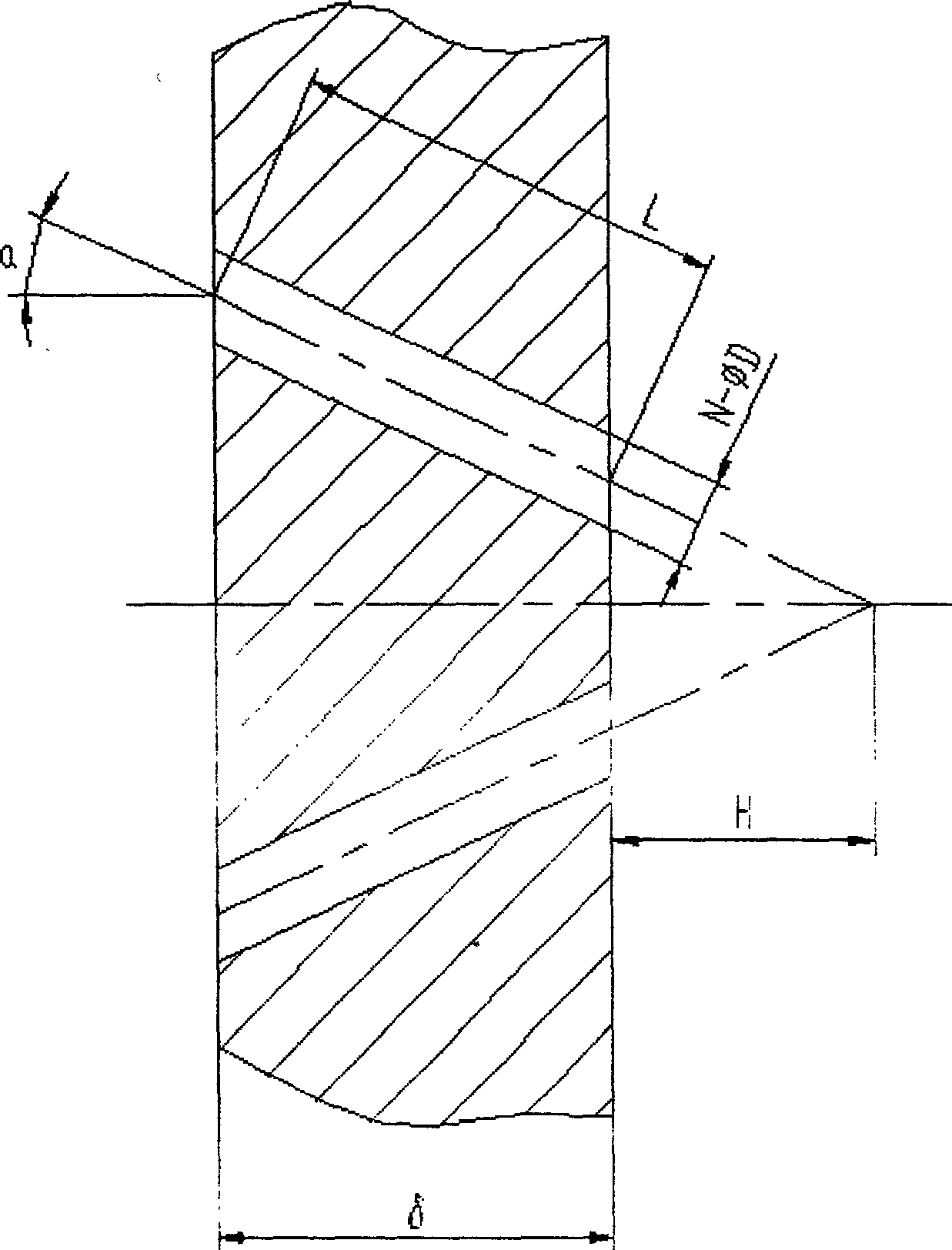

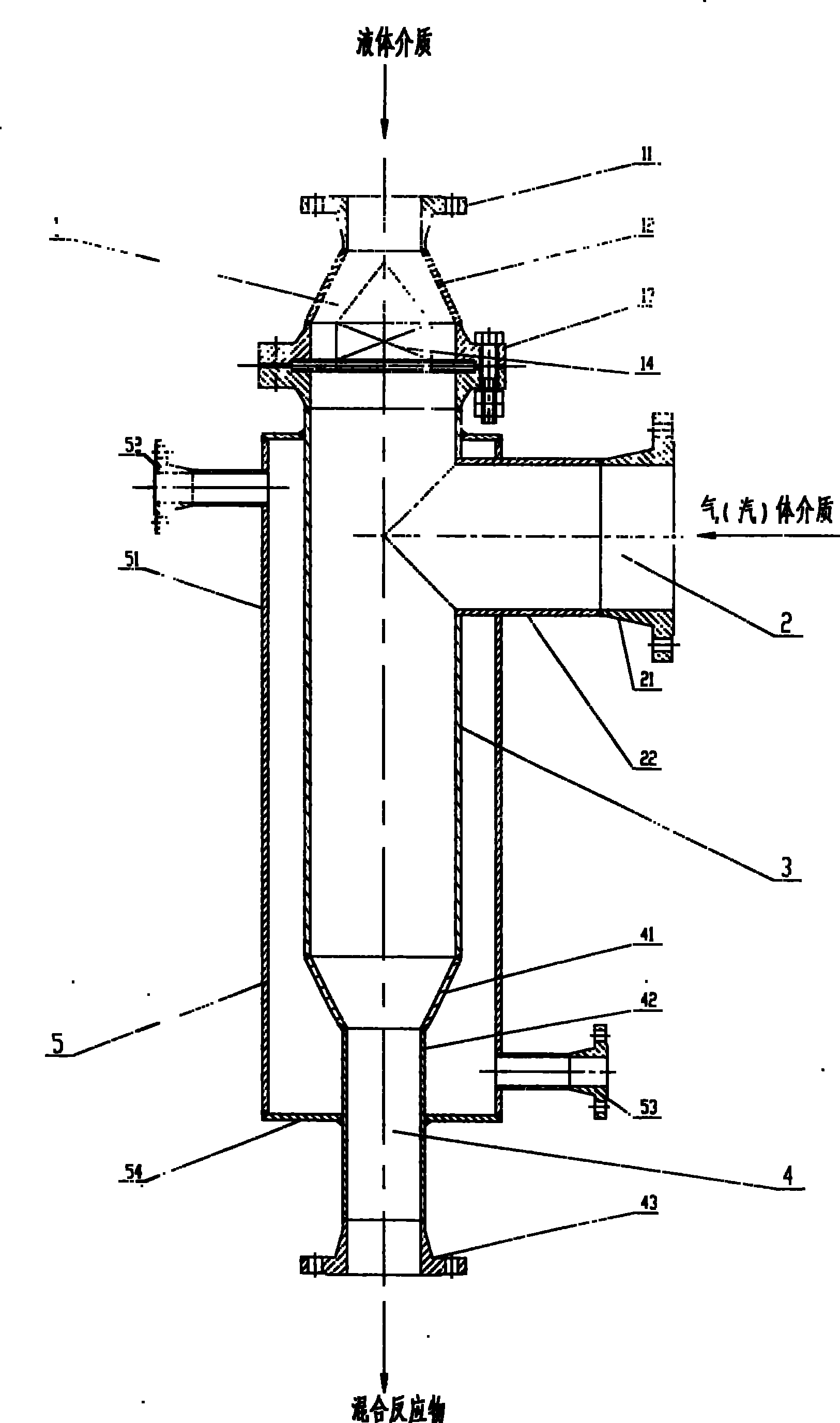

[0016] Depend on figure 1 , figure 2 As shown, a high-pressure liquid-gas / liquid-vapor tube-type rapid mixing reactor mainly consists of a liquid inlet atomization assembly 1, a gas / steam inlet assembly 2, a vessel body 3, a mixture convergence outlet assembly 4 and an outer casing assembly 5 Composition, wherein: the front end of the long tubular body 3 is provided with a liquid inlet diffusion atomization assembly 1 composed of a liquid inlet flange 11, an expansion tube 12, a flange assembly 13 and an atomizing disc 14, and is connected with the body 3 screw connection, a gas / steam inlet assembly 2 with a gas / steam inlet flange 21 and a connecting pipe 22 is provided in the middle of the body, and a converging pipe 41, a connecting pipe 42 and a mixture outlet method are arranged at the rear end of the body 3 The mixed reactant converging outlet assembly 4 composed of blue 43, the outside of the body 3 is surrounded by an outer casing assembly 5 composed of a long cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com