Laser block press

A technology of laser laser and molding machine, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of single pattern, labor-consuming, complicated production process of laser marking products, etc., and achieve unique laser pattern effect, simple process steps, The effect of protecting environmental resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

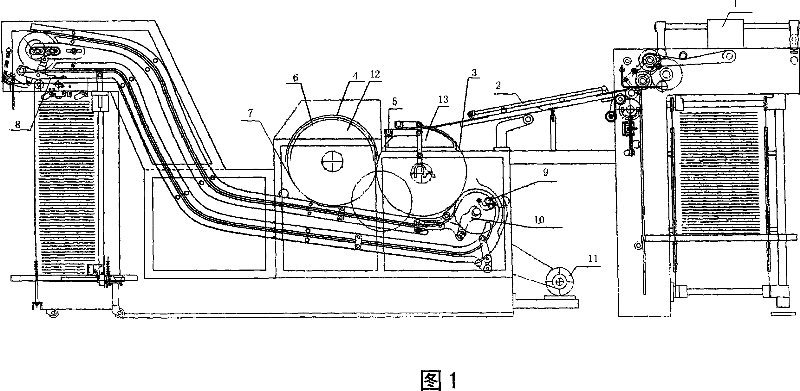

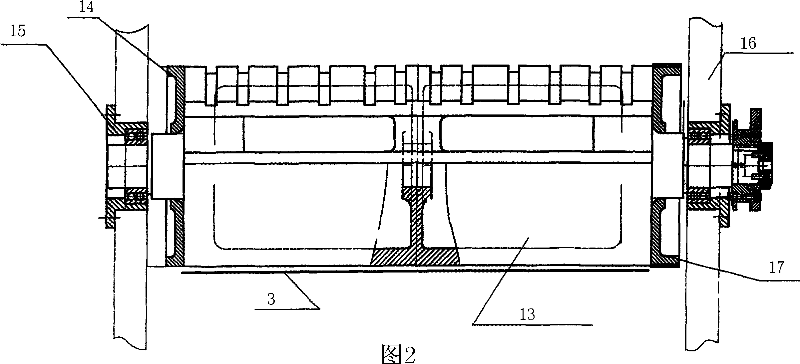

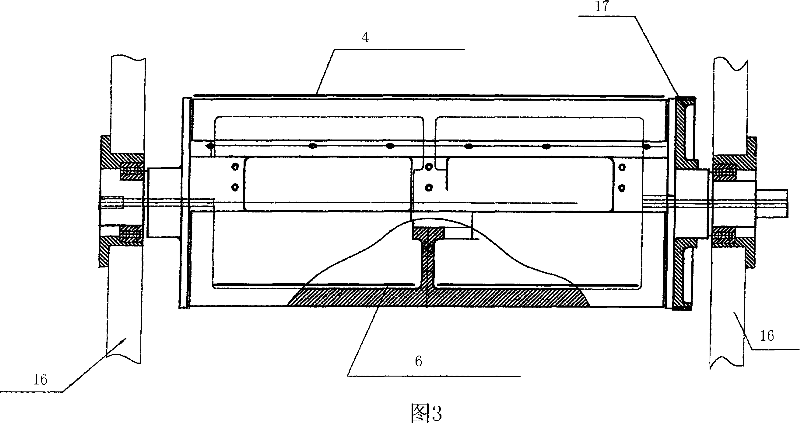

[0011] As shown in FIG. 1, the present invention relates to a laser laser molding machine. The laser laser molding machine is provided with a paper feeder 1, a paper feeding part at the downstream end of the paper feeding device, and a downstream end of the paper feeding part. The contacting impression cylinder 13, the printing plate cylinder 12 engaged with the impression cylinder, and a laser printing plate 4 is arranged on the periphery of the printing plate cylinder, and a paper roll is arranged on the periphery of the impression cylinder. When the laser logo needs to be printed, the to-be-printed paper enters the press through the feeder, and the to-be-printed paper enters the wrapping paper roll of the impression cylinder through the paper feeder, and the plate cylinder and the impression cylinder are meshed with each other. , the laser pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com