Drilling type well wall coring device

A technology of core extractor and borehole wall, which is applied in the direction of earthwork drilling, wellbore/well parts, etc., which can solve the problems of not accurately reflecting the original characteristics of the reservoir, high price, low power, etc., to reduce sticking in the well The risk on the wall, the safety of coring construction, the effect of large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

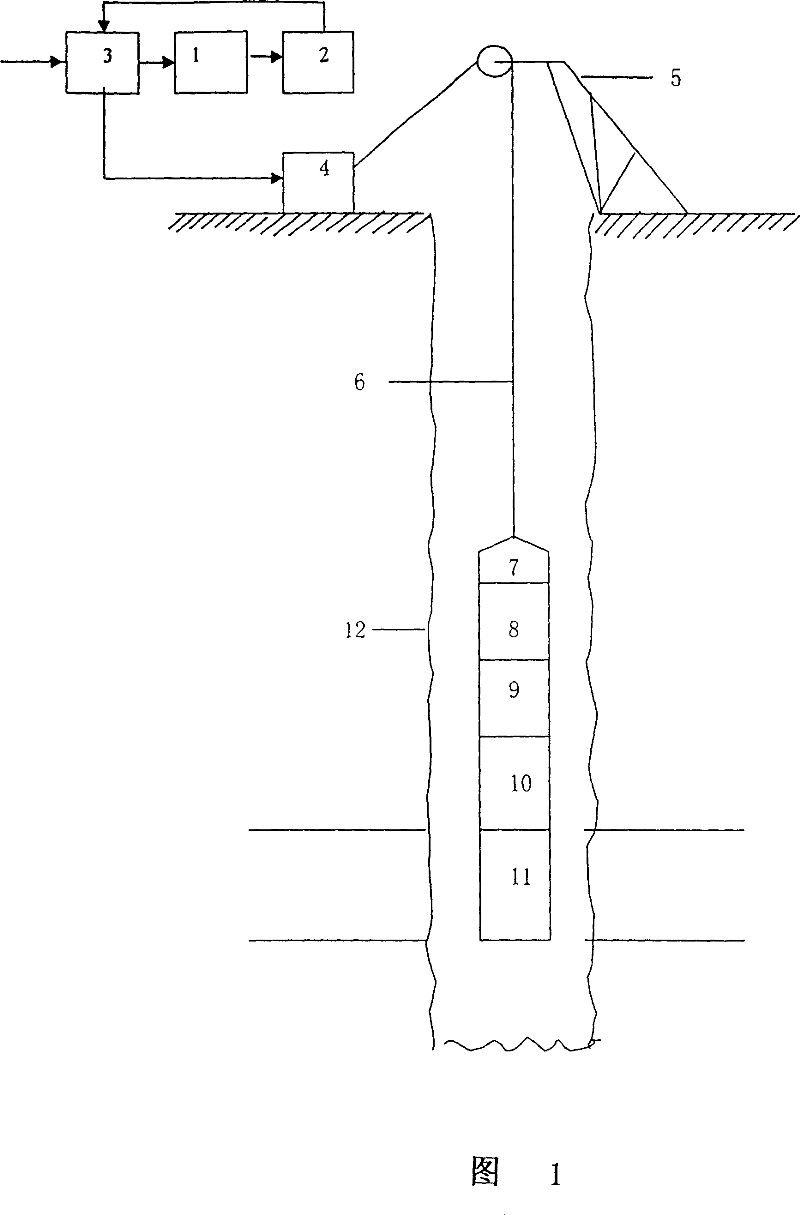

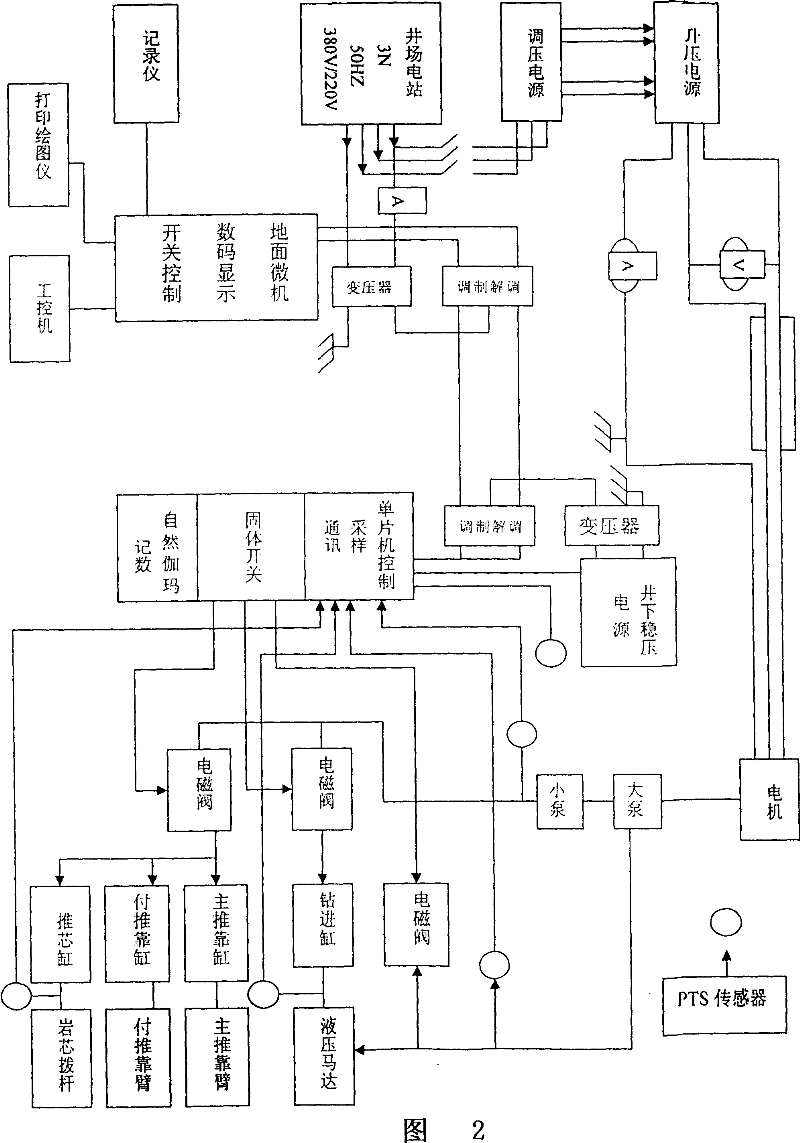

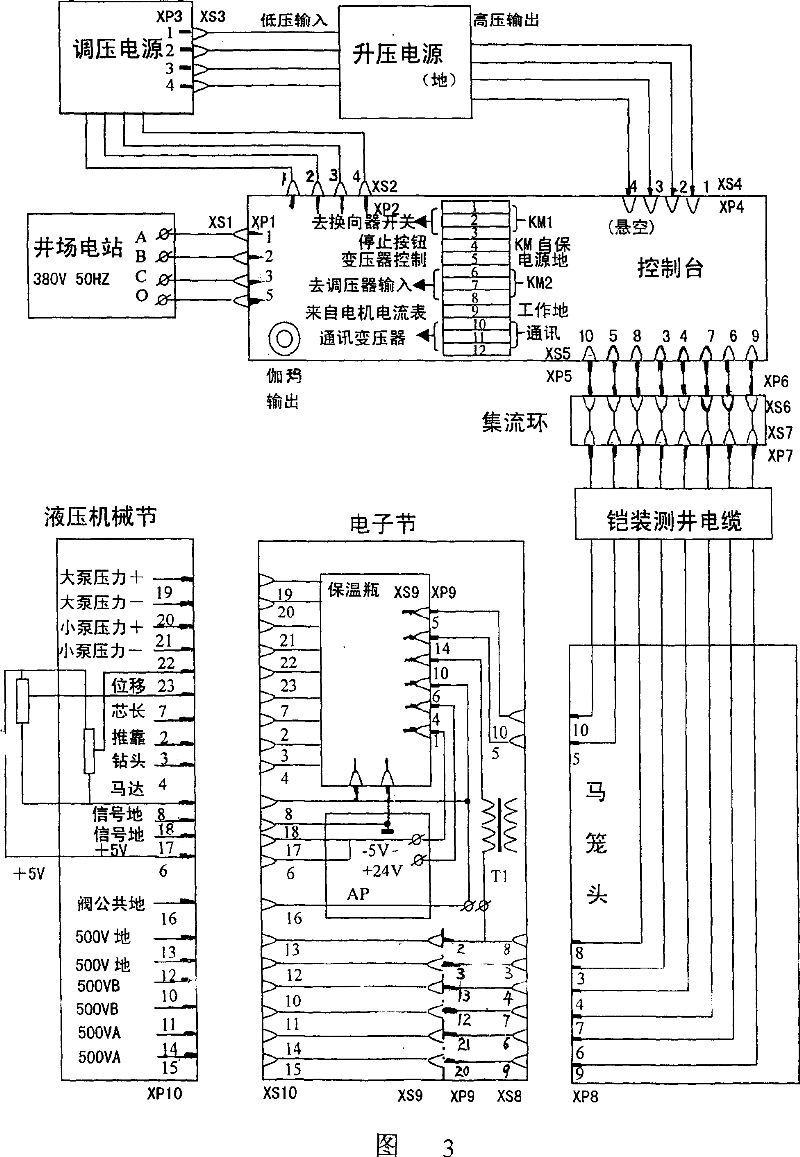

[0024] As shown in Figures 1, 2, and 3, the drilling-type borehole wall coring device disclosed by the present invention is mainly composed of two parts: the ground electrical control system and the downhole coring system; The ring and logging drawworks cables are connected to the downhole coring system.

[0025] The ground electrical control system is arranged on the ground, and it is mainly composed of a ground voltage regulating cabinet 1, a booster cabinet, 2 control cabinets 3, and a logging winch 4 (digital logging). Its main function is to provide power to downhole instruments, send out control signals, receive and process data fed back by various downhole sensors, and display and monitor the downhole coring system in real time. The ground electrical control system is connected to the collector ring through the collector ring cable, and the collector ring is connected to the downhole coring system through the logging cable 6 erected on the derrick 5 .

[0026] The down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com