Horomill

A horizontal roller mill and roller shaft technology, applied in the field of horizontal roller mills, can solve the problems of high pressure, large floor space, and reduced material layer stability, so as to achieve low equipment wear, low material flow rate, and small floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

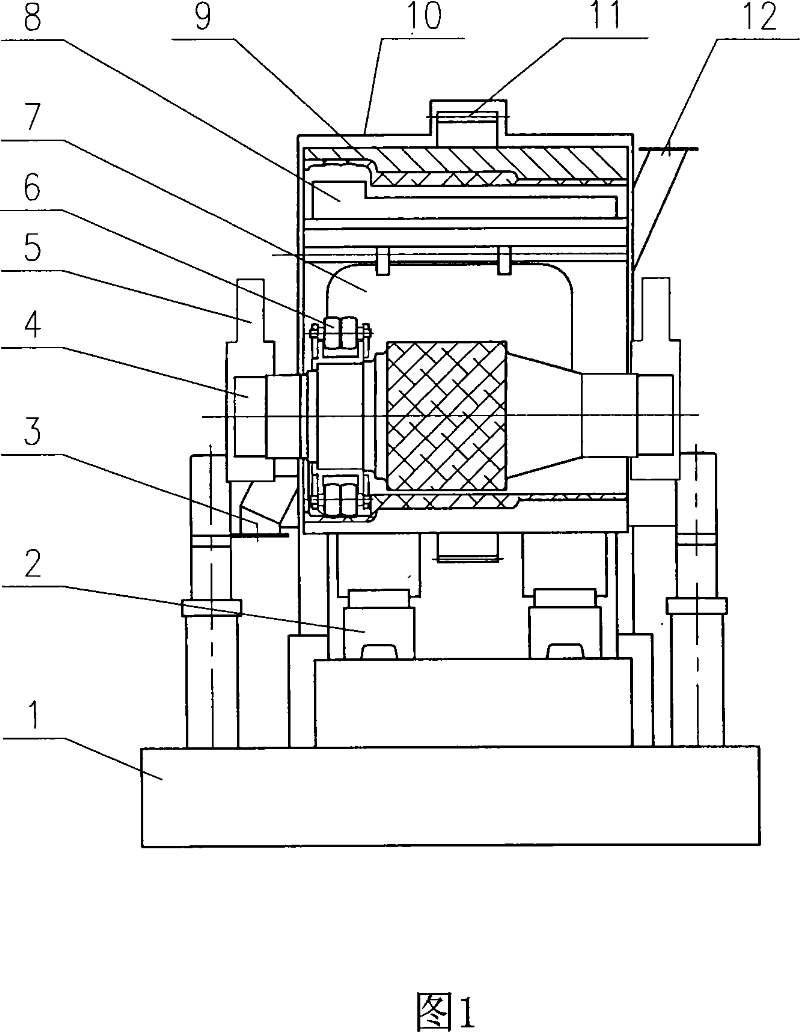

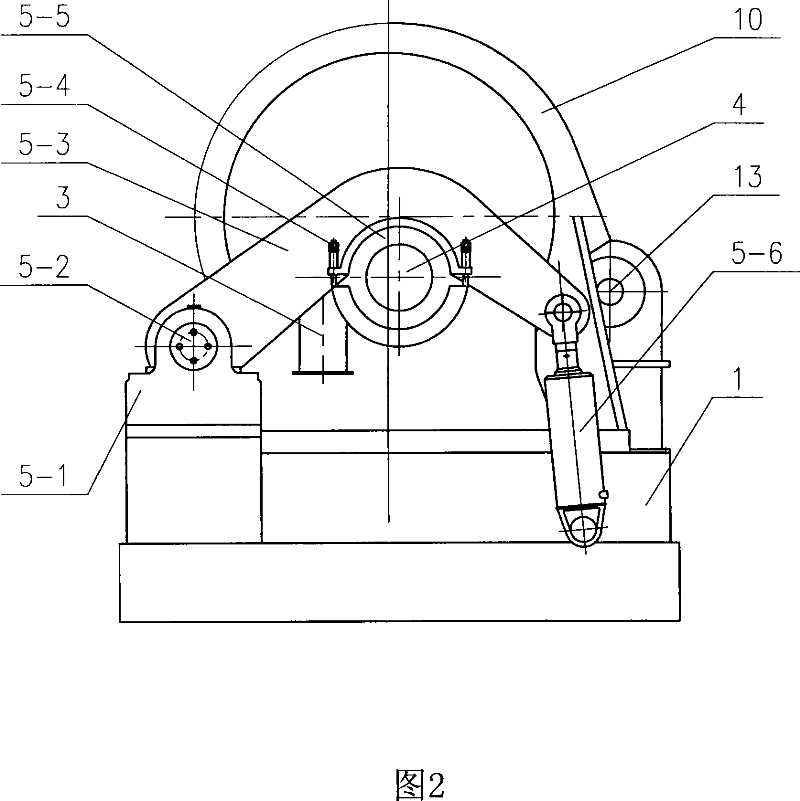

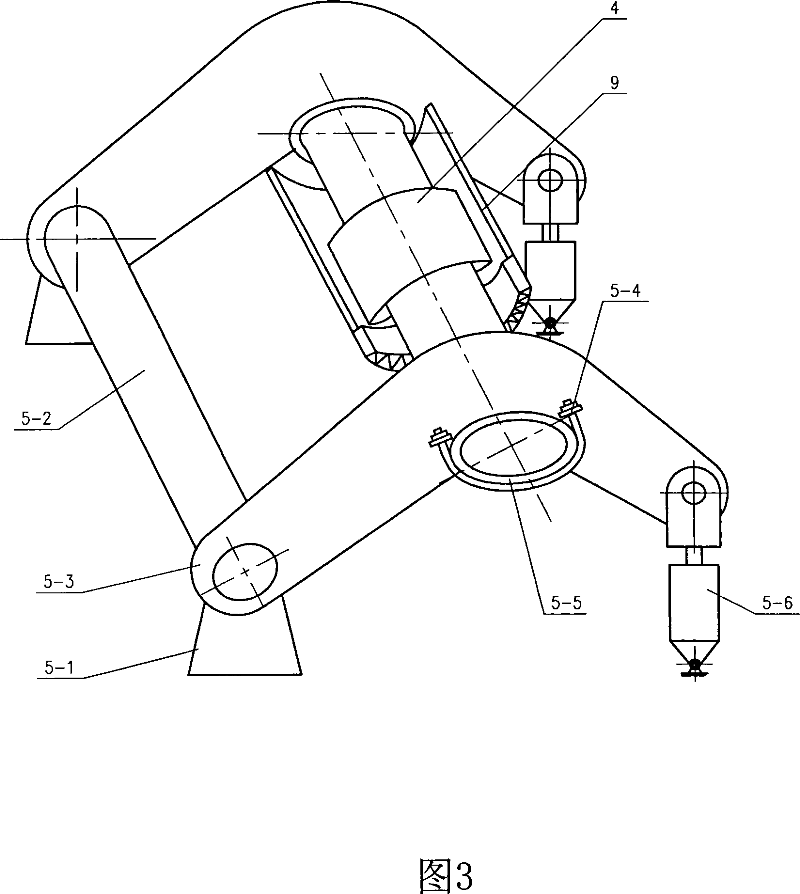

[0030]The present invention includes: a cylinder body 9, a pressure roller 4, a sliding support seat 2, a transmission device, a pressurizing device 5, a spherical grinding device 6, a material guiding device 7 and a scraping device 8. The pressure roller 4 is placed in the cylinder 9, and the inner wall of the cylinder 9 is provided with a cylindrical main liner 6-10 corresponding to the pressure roller 4. Both ends of the cylinder body 9 are respectively provided with inlet and outlet ports 12 and 3 . Two main sliding bearing seats 2-1 and two auxiliary sliding bearing seats 2-2 are correspondingly placed on both sides below the cylinder body 9, and the structures of the main and auxiliary sliding bearing seats 2-1 and 2-2 are the same as those in the prior art. , all contain support tile 2-3, support seat 2-4 on the spherical surface, support seat 2-5 under the sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com