Method of for cutting un-orthogonal crossed big connecting pipe hole by the digital controlled fire on the thick cylinder

A flame cutting, thick-walled cylinder technology, applied in gas flame welding equipment, combustion methods, welding equipment and other directions, can solve the problems of labor-intensive, material resources, and difficulty in ensuring the accuracy of manual block cutting, and can solve the problems of oblique opening, The effect of avoiding manual operation errors and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The shape of the opening of the cylinder is saddle-shaped, and the connecting angle with the connecting pipe is 45°.

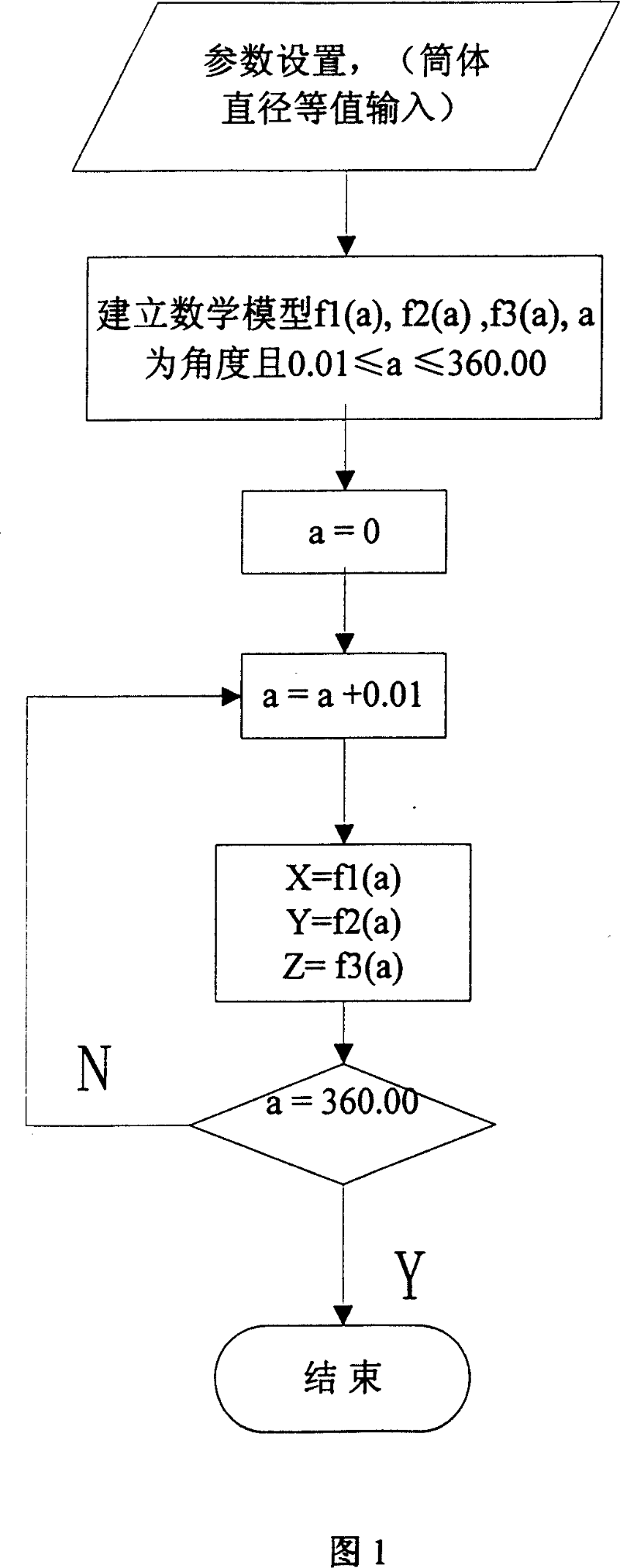

[0027] As shown in Figure 1, it is a flow chart of the gas cutting program. Through the programming of the W250 CNC boring and milling machine 5 of the Czech SKOD company, the diameter of the cylinder is input according to the product's opening size requirements. As shown in Figure 6, the three-dimensional mathematical model is established as follows:

[0028] X Y Z = sin θ 1 0 cos θ 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com