Method for preparing cristobalite by calcining quartz

A cristobalite and quartz technology, applied in the field of calcined quartz to prepare cristobalite, can solve the problems of large amount of additives added, low conversion rate, influence on the purity of cristobalite, etc., and achieve the effects of high conversion rate, reduced energy consumption, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

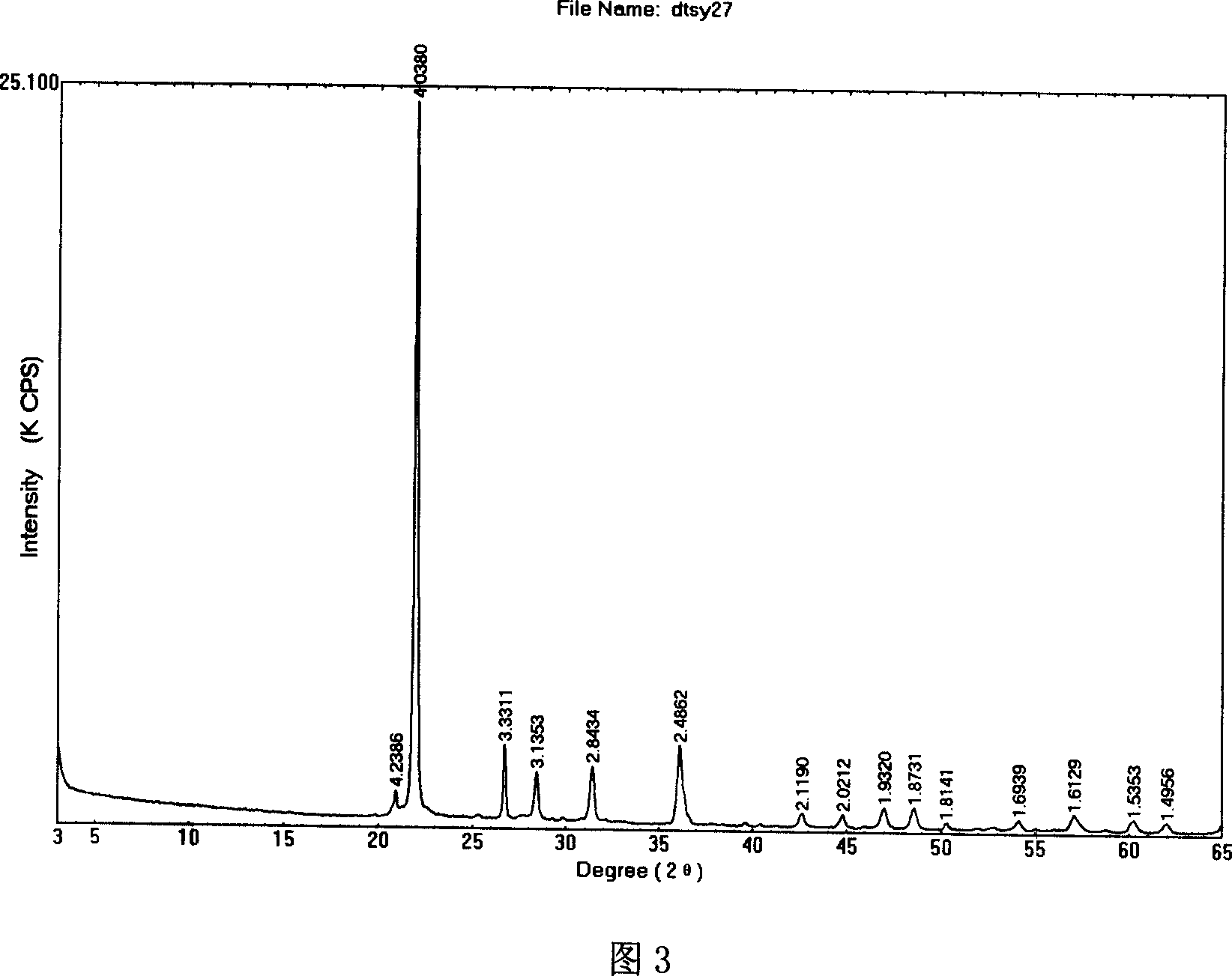

Embodiment 1

[0026] Put 5.00g of quartz powder less than 0.149mm into the corundum crucible, add yttrium oxide with a weight of 2‰ of the quartz powder, add sodium carbonate with a weight of 8‰ of the quartz powder, add barium fluoride with a weight of 5‰ of the quartz powder, mix well , placed in a silicon molybdenum rod box-type resistance furnace, heated to 1300 °C at a rate of 4 °C per minute, and kept at 1300 °C for 6 hours to obtain a cristobalite product, and the product was subjected to X powder crystal diffraction analysis to obtain XRD pattern 3 . It can be seen from Figure 3 that the cristobalite conversion rate is 95.23%.

Embodiment 2

[0028] Put 5.00g of quartz powder less than 0.149mm into the corundum crucible, add yttrium oxide with a weight of 5‰ of the quartz powder, add sodium carbonate with a weight of 9‰ of the quartz powder, add barium fluoride with a weight of 3‰ of the quartz powder, mix well , placed in a silicon molybdenum rod box-type resistance furnace, heated to 1300 °C at a rate of 4 °C per minute, and kept at 1300 °C for 6 hours to obtain a cristobalite product, and the product was subjected to X powder crystal diffraction analysis to obtain XRD pattern 4 . It can be seen from Figure 4 that the cristobalite conversion rate is 94.34%.

Embodiment 3

[0030] Put 5.00g of quartz powder less than 0.149mm into the corundum crucible, add yttrium oxide with a weight of 4‰ of the quartz powder, add sodium carbonate with a weight of 8‰ of the quartz powder, add barium fluoride with a weight of 5‰ of the quartz powder, mix well , placed in a silicon molybdenum rod box-type resistance furnace, heated to 1300 °C at a rate of 4 °C per minute, and kept at 1300 °C for 6 hours to obtain a cristobalite product, and the product was subjected to X powder crystal diffraction analysis to obtain XRD pattern 5 . It can be seen from Figure 5 that the cristobalite conversion is 95.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com