Windbreak grid wall

A technology of grid wall and grid plate, which is applied in the field of windproof grid wall, can solve the problems of unsightly wall surface, increased wall load, large folding amount, etc., and achieve the effect of avoiding waste of raw materials, reducing processing cost, and improving the blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

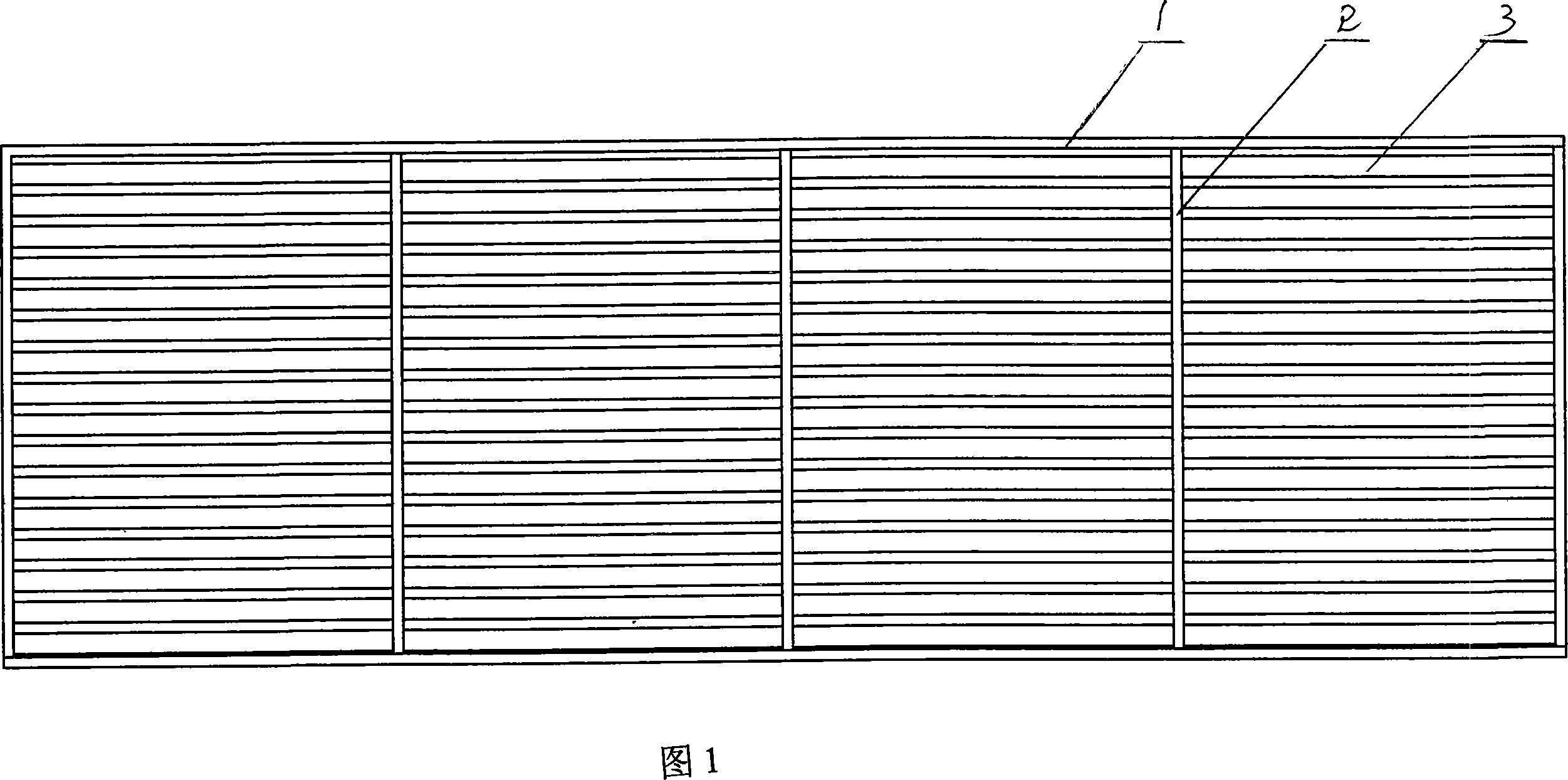

[0016] A windproof grid wall includes a frame 1, and at least two curved grid panels 3 are arranged in parallel in the frame 1. Beads 2 are also pressed on the curved grid plate 3 . Curved grids are made of steel or iron or other non-metallic materials.

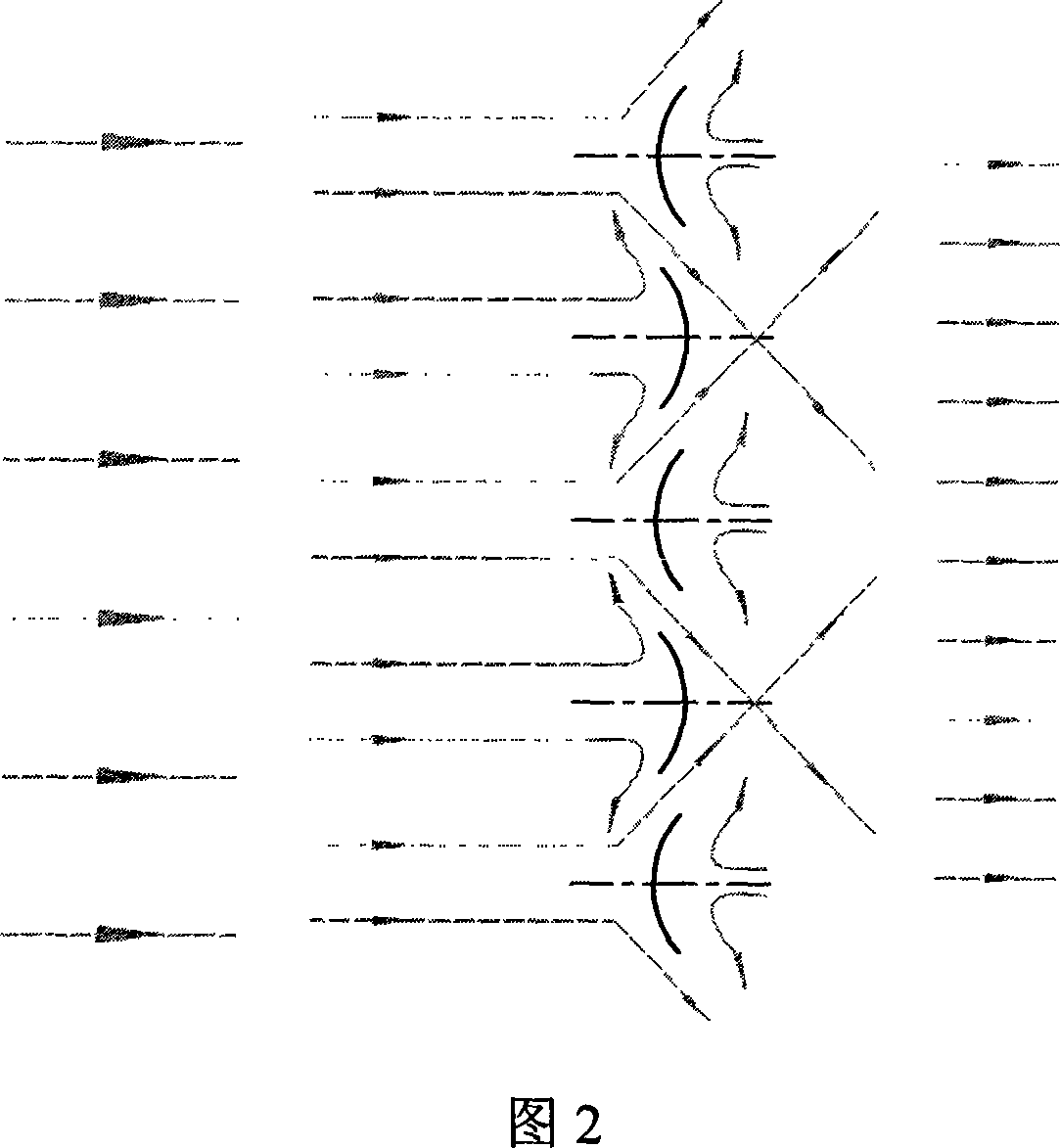

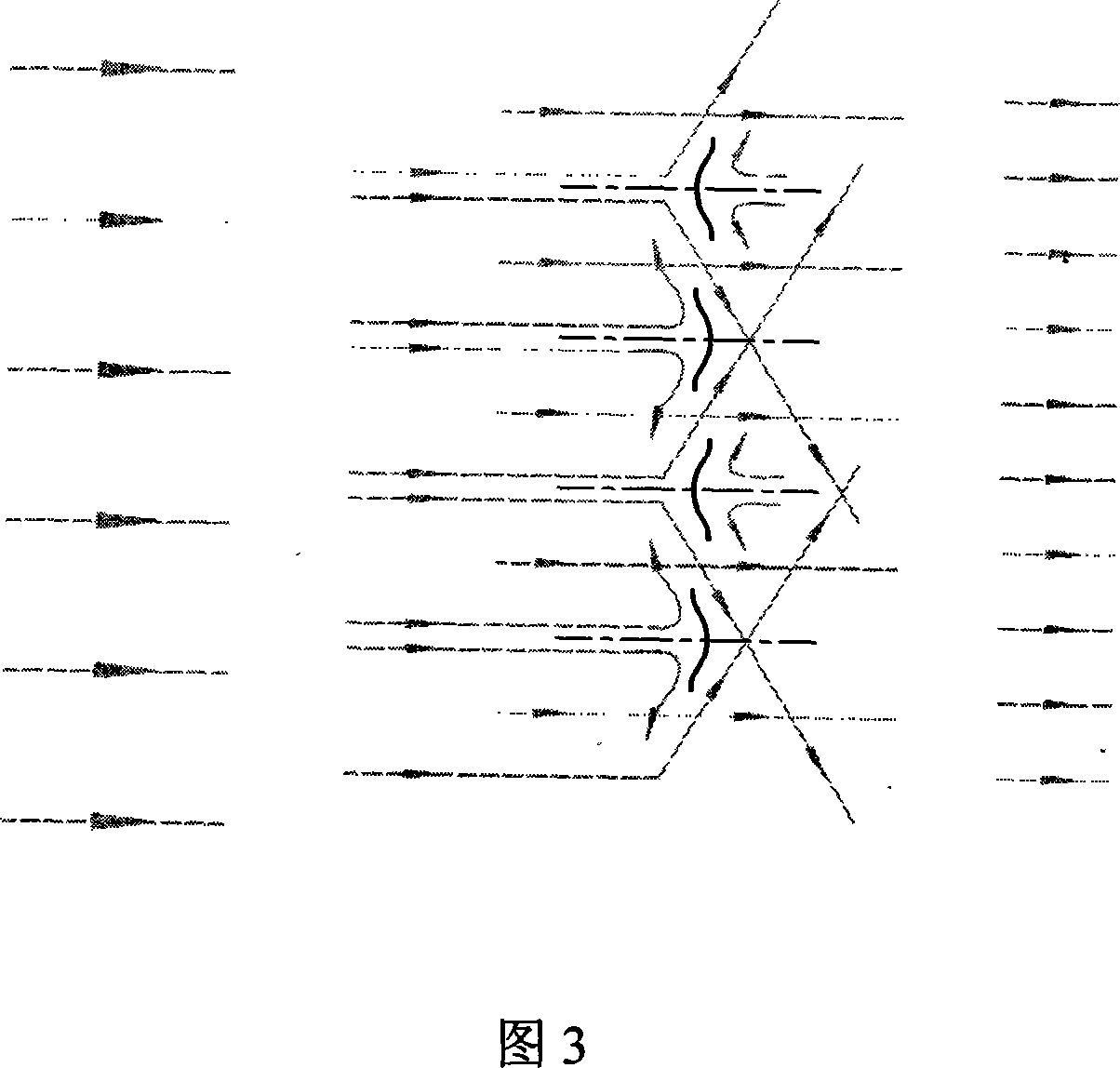

[0017] The curved grid plate is bent into C-shape, S-shape and Ω-shape.

[0018] The arrangement direction of the curved grid plates can be in the same direction, and the arrangement direction of the curved grid plates can also be alternately reversed.

[0019] The total width of the curved grid can be 20-200mm, and the discharge angle between the center line of the curved grid and the horizontal direction is 0-180°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com