Semiconductor package stack with through-via connection

A through-hole, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems that it is not easy to reduce the overall size and packaging area, require space, limit miniaturization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

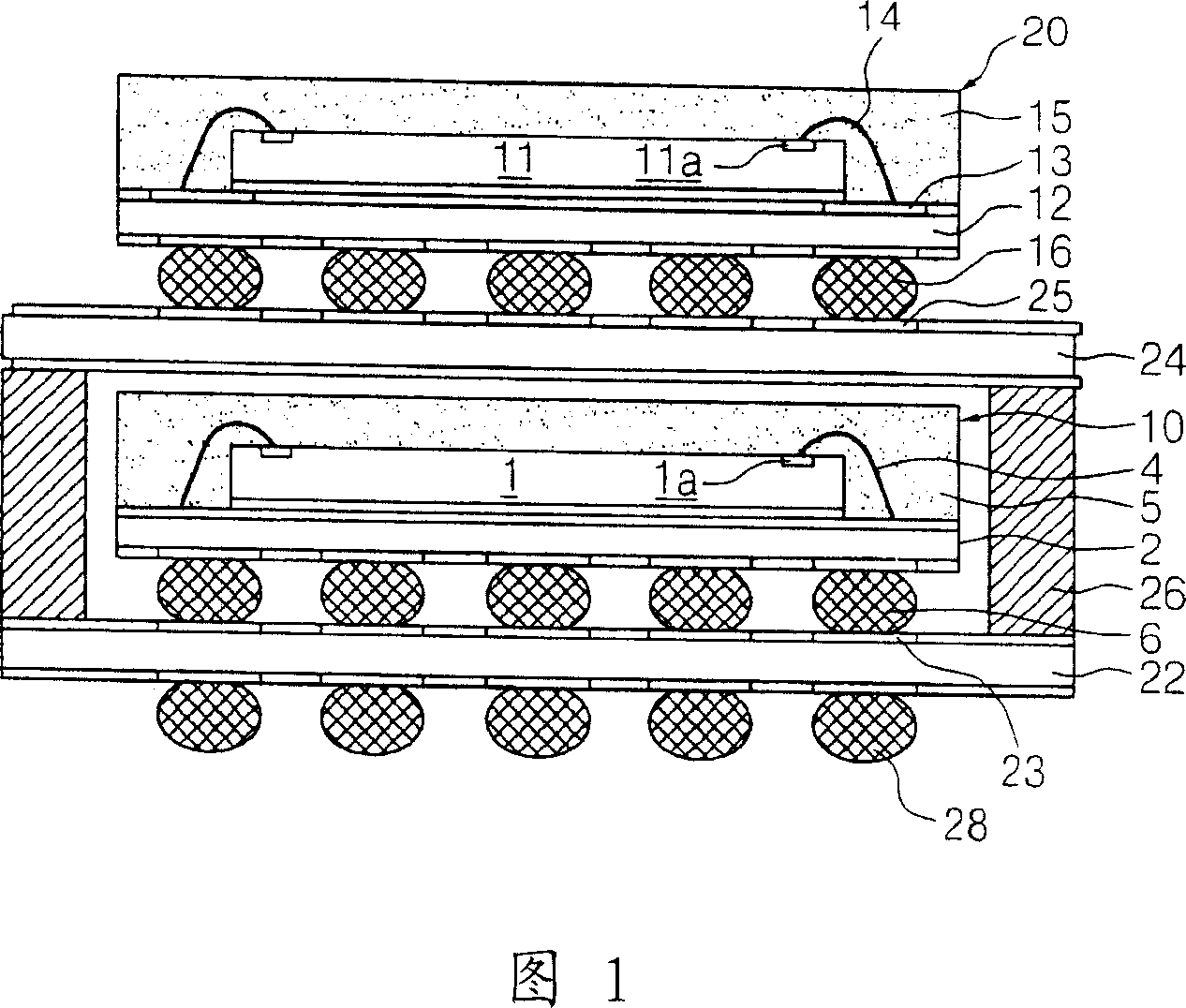

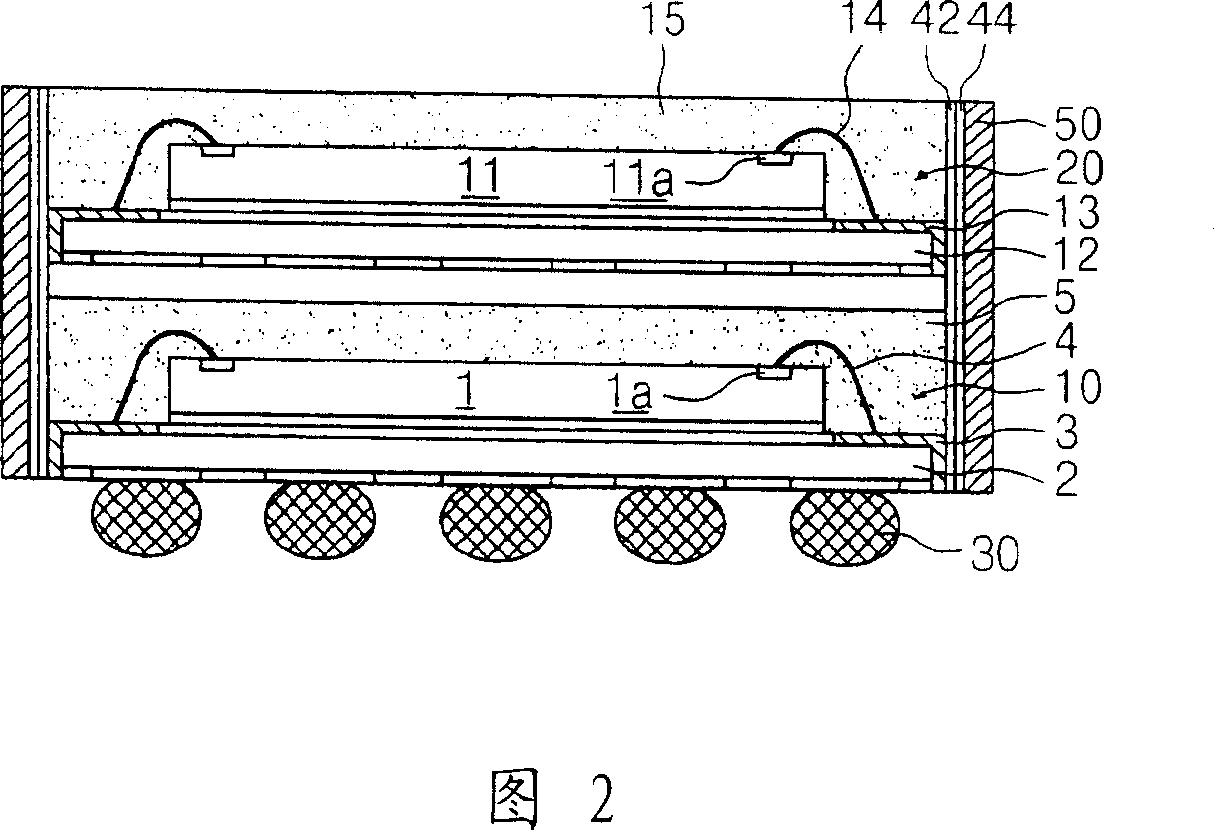

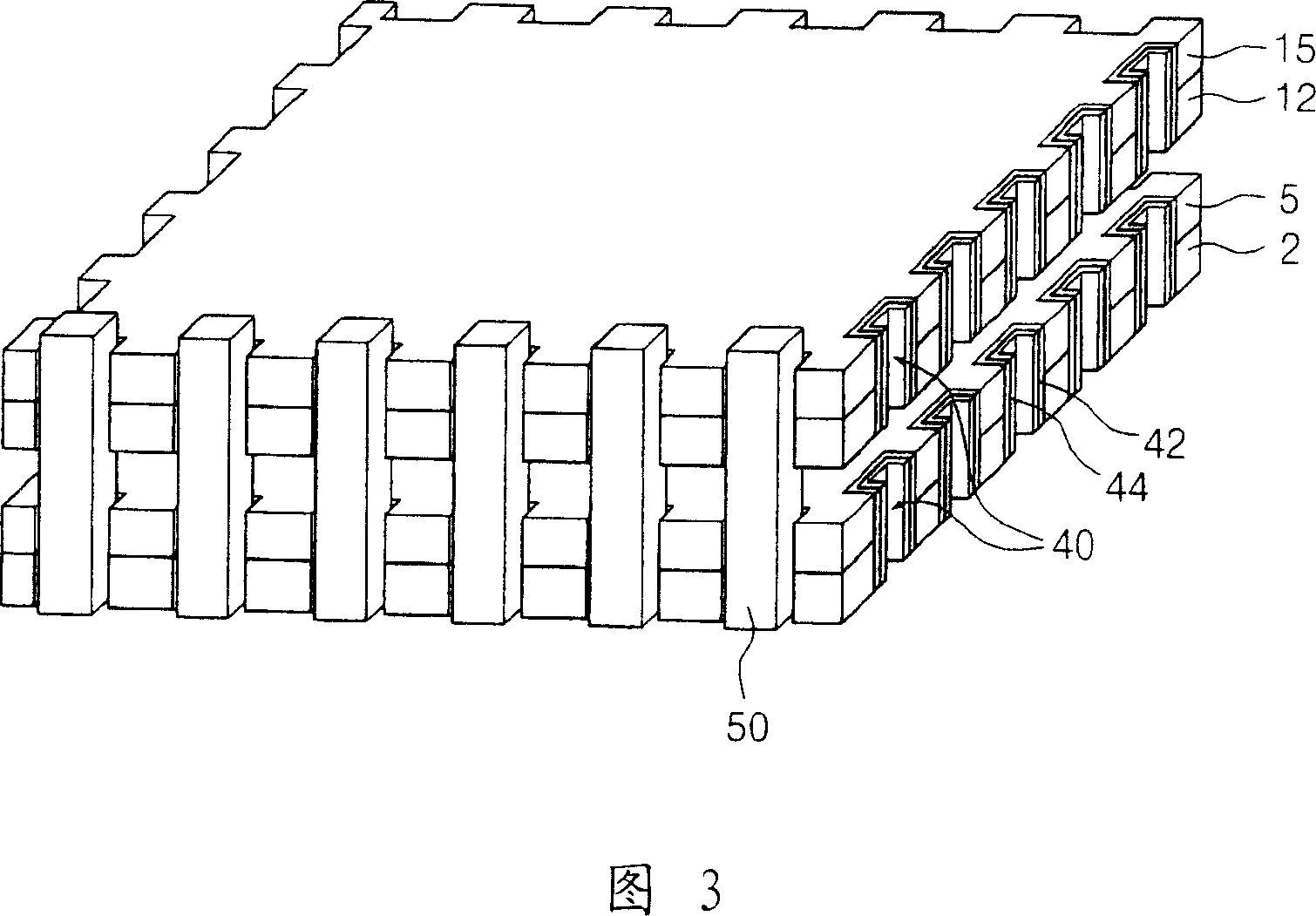

[0026] Next, preferred embodiments of the present invention will be described with reference to the relevant drawings. In the following descriptions and drawings, the same reference numerals will be used to designate the same or similar components, and repeated descriptions of the same or similar components will be omitted.

[0027] According to an embodiment of the present invention, when FBGA packages are stacked together, plated through holes are formed on the side of each package, and conductive leads are disposed in each plated through hole for electrical connection between the package stacks.

[0028] Because the present invention does not need to add extra space when performing package stacking. Therefore, the overall size and thickness of the package stack can be reduced to meet the volume requirement of the current semiconductor technology. In addition, compared with the conventional technology, the present invention does not use either the substrate or the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com