Bus groove transmission device and multi-layer bus groove electric connection method

A technology of power transmission device and busway, which is applied to the installation of circuit devices, conductive connections, and busbars. It can solve problems such as automatic stoppage, burnout of conductors, and increased costs, so as to reduce manufacturing costs and avoid excessive current. The effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

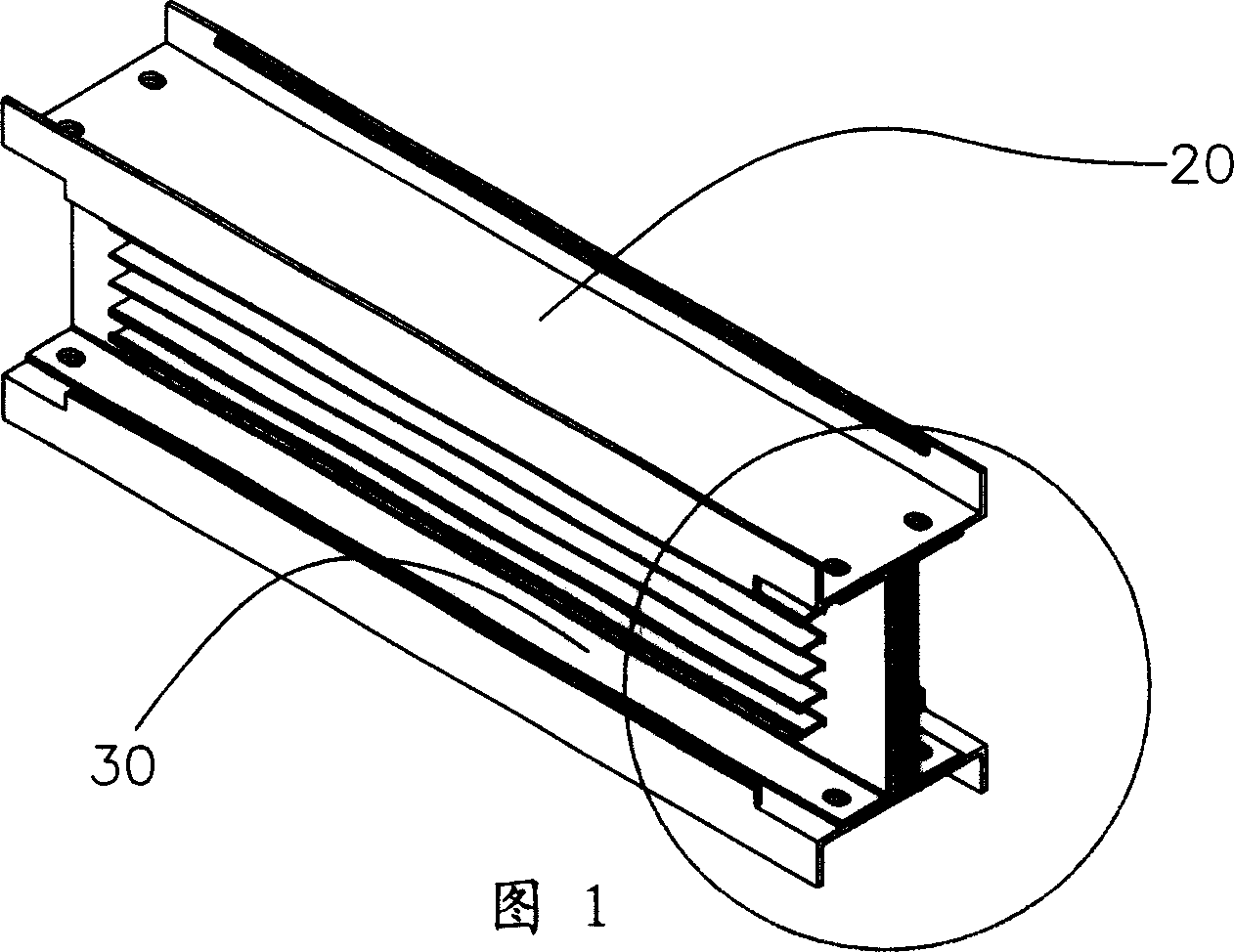

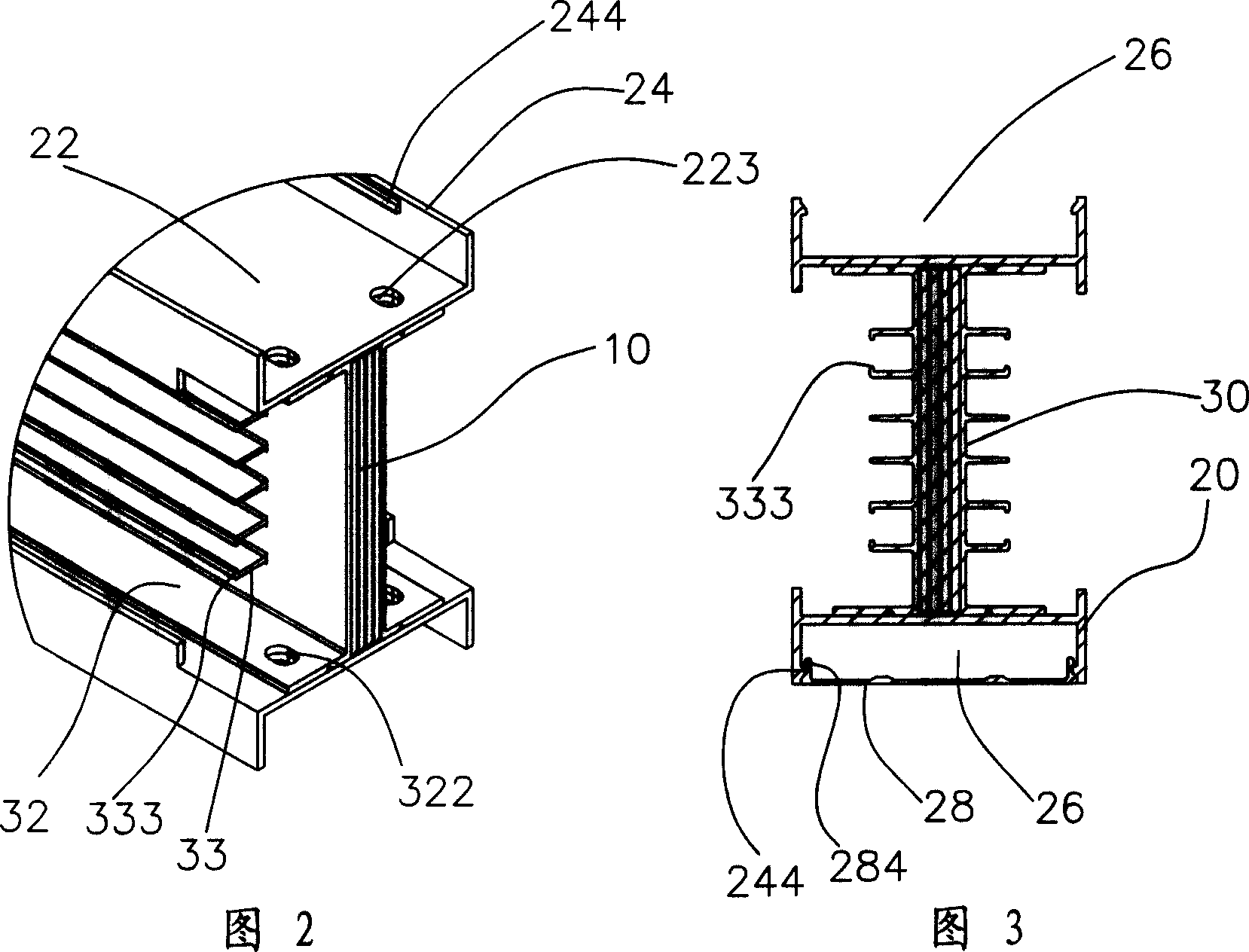

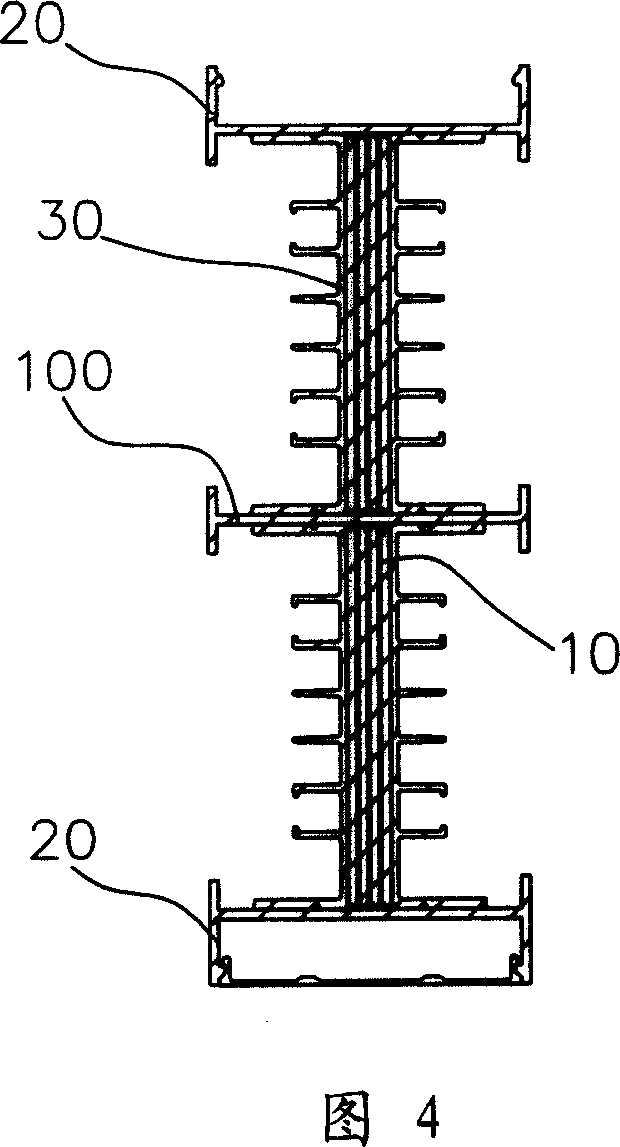

[0031] Please refer to Figure 1 to Figure 3, the bus duct power transmission device of the present invention includes multiple dense bus ducts in this embodiment, here we first introduce the single-layer bus duct with simple structure as an example, in which the bus duct is used to install A set of mutually insulated conductors 10, such as conductive copper bars, is provided. In this embodiment, the set of conductors 10 includes four conductive copper bars. The busway includes a pair of cover plates 20 and a pair of side plates 30 , and the conductor group 10 is installed in the space enclosed by the pair of cover plates 20 and the pair of side plates 30 .

[0032] A pair of cover plates 20 are symmetrical in shape, and one of them will be introduced here. The cover plate 20 is roughly U-shaped, including a body 22, and a pair of side walls 24 extend upwards from the two side edges of the body 22 to form a measurement and control wire slot 26, for laying out measurement and co...

Embodiment 2

[0046] As another embodiment of the present invention, the bus duct power transmission device of the present invention can adopt other types of bus ducts, such as air-type bus ducts, high-performance bus ducts, fire-resistant bus ducts, waterproof bus ducts, and air additionally insulated bus ducts Groove, high-voltage co-phase closed bus duct, etc.

[0047] Cover plate 20, side plate 30, connecting cover plate 40, connecting side plate 50 all can adopt asymmetric shape, such as, can only have the side plate 30 of one side to be provided with heat sink 33 structures, can only have the cover plate 20 of one side to be provided with There are 26 structures for measuring and controlling wire slots.

[0048] At least one hook member 60 can be arranged in each buckle slot 525 , and the hook member 60 can be directly fixed on the side plate 30 by other means, such as buckle, riveting, welding and so on.

[0049] The slot cover 28 can be pivotally connected to the measurement and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com