Spiral support and manufacturing method thereof

A technology of helical and tubular materials, applied in the field of tubular helical stents, can solve the problems of high cost, complex structure and disconnection of the helix, and achieve the effects of avoiding energy loss, simple manufacturing technology and uniform connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

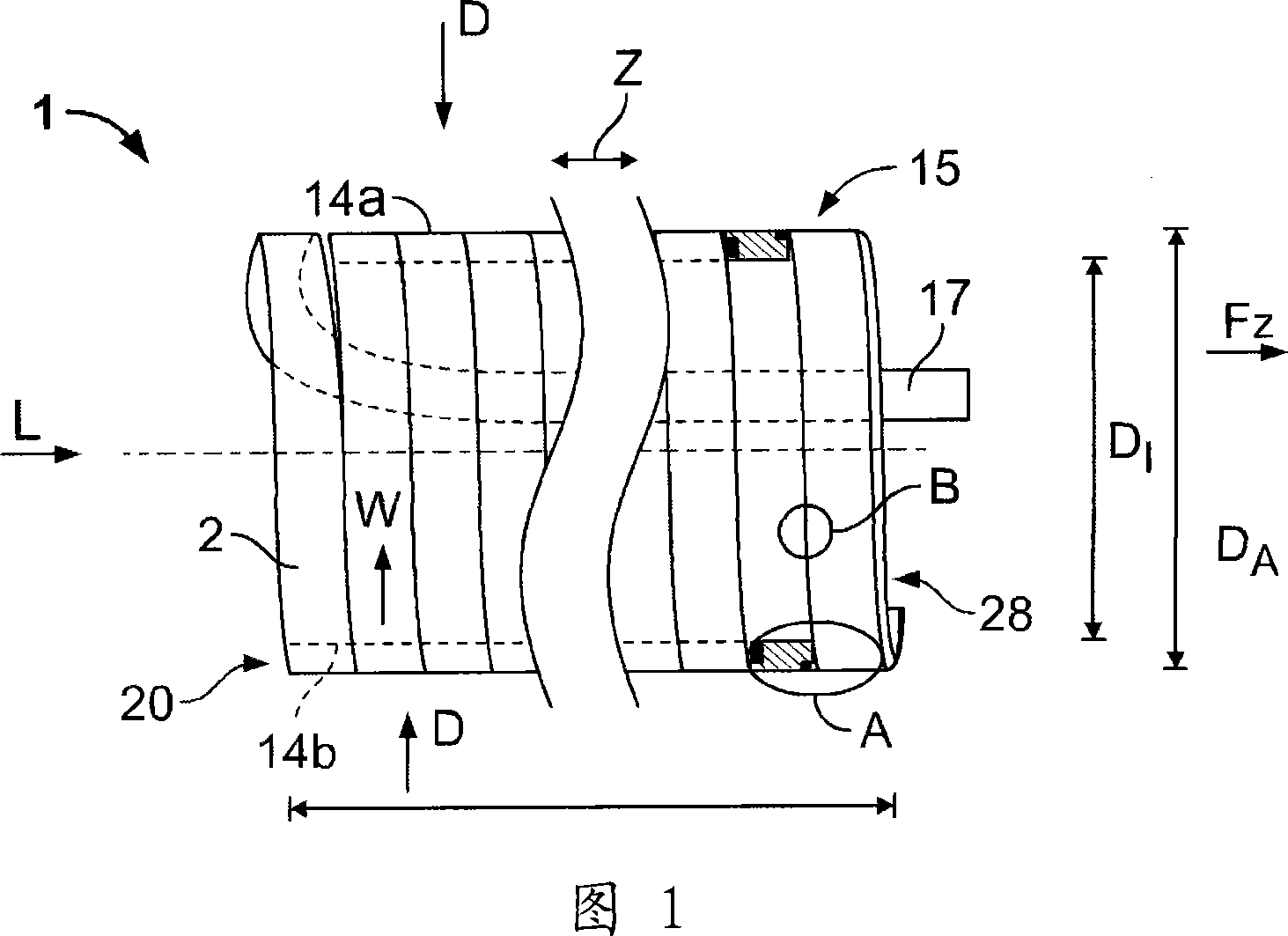

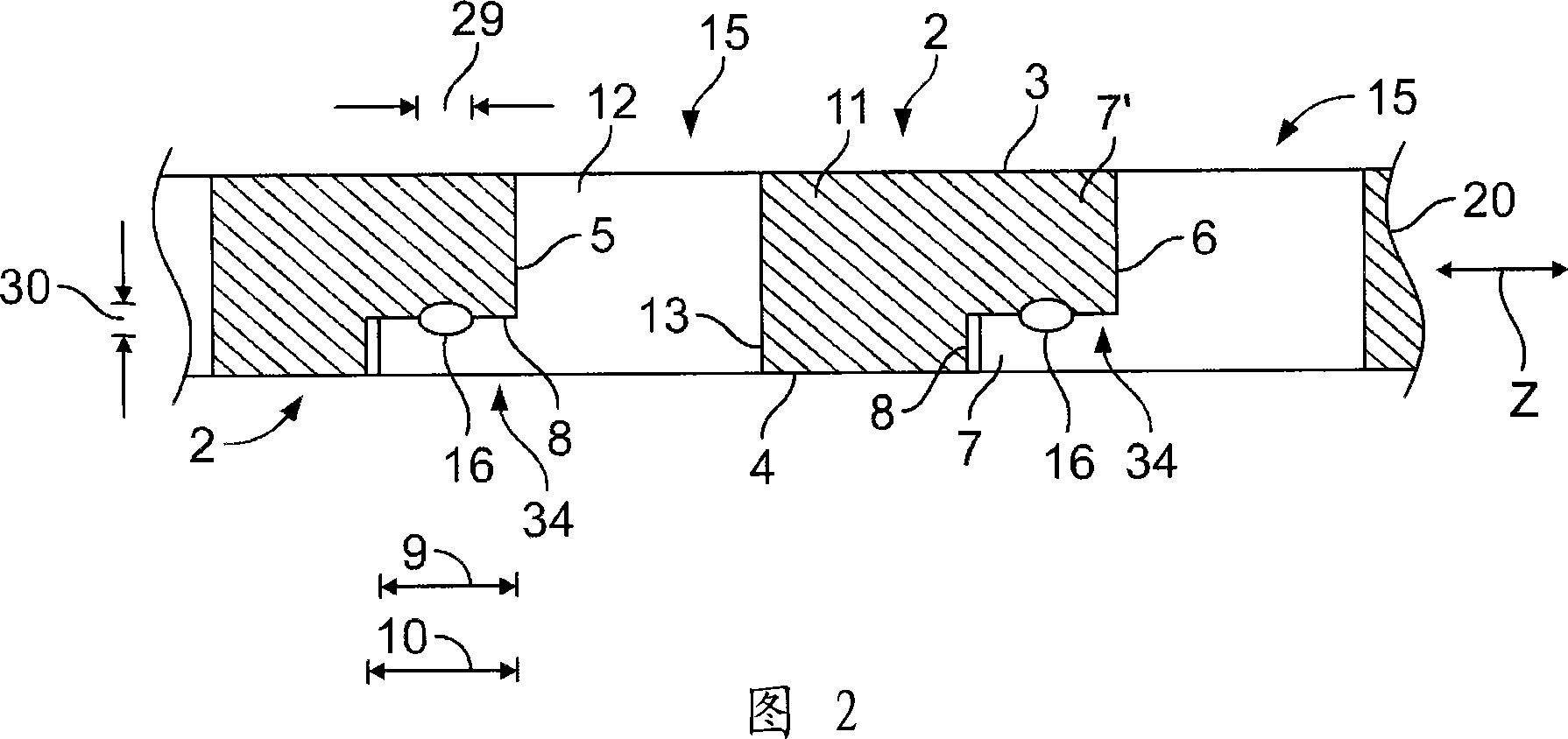

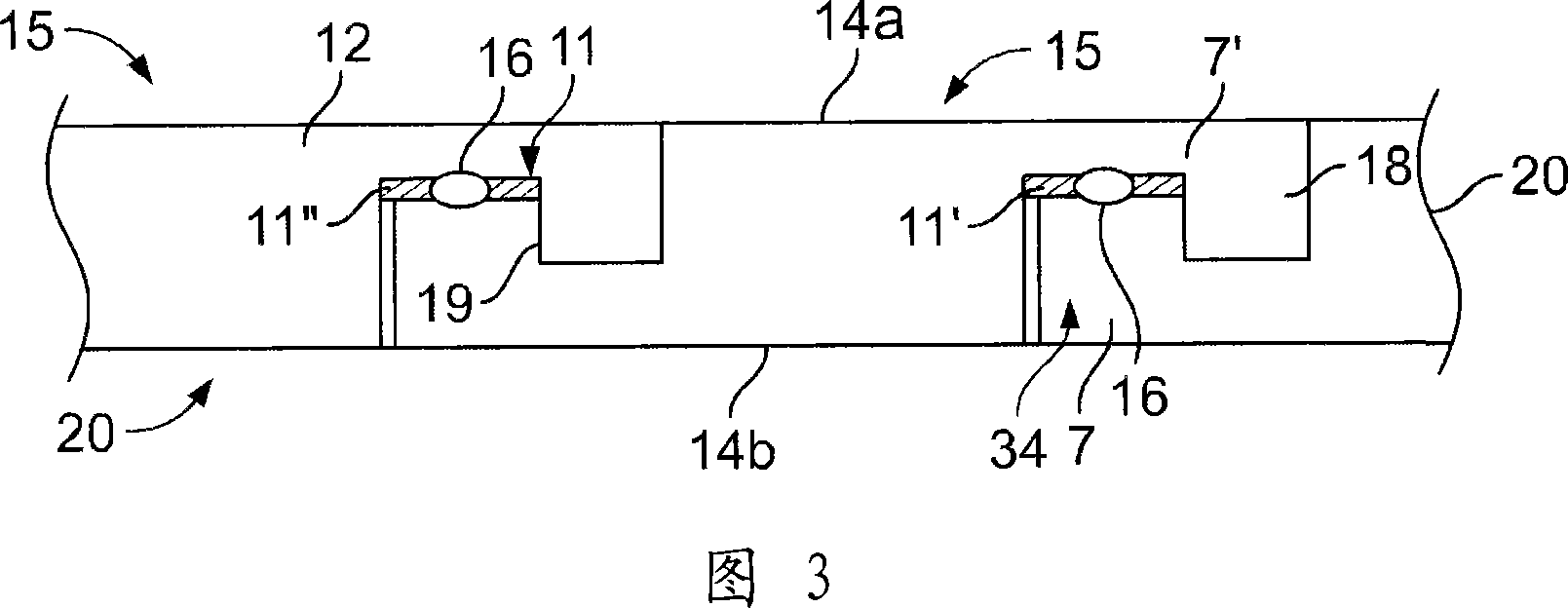

[0043] First, the general configuration of the helical stent 1 according to the present invention will be described with reference to FIGS. 1 and 2 and the exemplary embodiment shown therein.

[0044] The helical support 1 consists of an extruded body 2 wound in a winding direction W with a plurality of loops 15 .

[0045] The extruded body 2 is configured as a substantially continuous strip-shaped body, which is produced, for example, by an extrusion method. In this way, theoretically, the helical stent 1 can be manufactured to an infinite length. In practice, the helical stent 1 is usually about 30 to 50 cm long. In cross section, the extruded body 2 is substantially rectangular in the embodiment shown in FIGS. 1 , 2 and 9 , with parallel upper and lower edges 3 , 4 and shorter side edges 5 , 6 . The side edges 5, 6 match each other. The rectangular protrusion 7 is arranged on the edge 6 side, and the rectangular groove 8 is arranged on the edge 5 side. The protrusion 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com